Hot Dipped Binding Wire 0.1mm to 6.0mm 0.2kg to 500kg/Roll Factory Price

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 250000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Hot Dipped Binding Wire 0.1mm to 6.0mm 0.2kg to 500kg/Roll Factory Price Description:

Galvanized Iron Wire has the characteristics of thick zinc coating, good corrosion resistance, firm zinc coating, etc.

Galvanized Iron Wire mainly used in construction, express way fencing, binding of flowers and wire mesh weaving. Galvanized iron wire according to manufacturing technique, it includes hot-dipped galvanized iron wire and electro galvanized iron wire. Mainly telecommunication equipment and materials, medical equipment and device, weaving of wire mesh, steel rope, and filtration mesh, high-pressure pipe, construction, arts and crafts.

2.Main Features of Hot Dipped Binding Wire 0.1mm to 6.0mm 0.2kg to 500kg/Roll Factory Price:

• Use widely

• Corrosion- resistant

• Durable

• Practical use

• Beauty Surface

• Versatile

3. Hot Dipped Binding Wire 0.1mm to 6.0mm 0.2kg to 500kg/Roll Factory Price Images

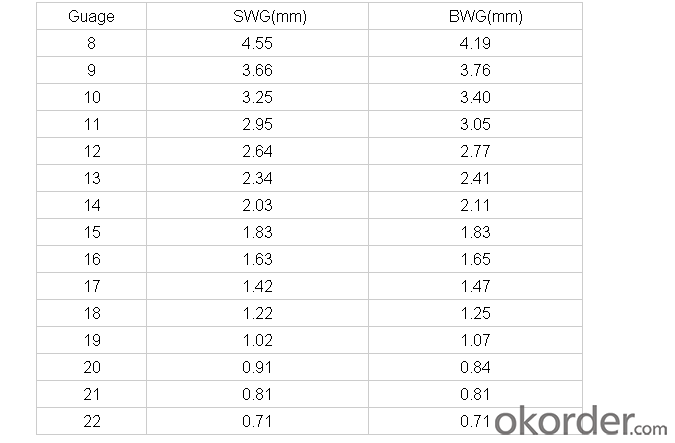

4.Hot Dipped Binding Wire 0.1mm to 6.0mm 0.2kg to 500kg/Roll Factory Price Specification

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your products?

One of the most biggest manufacturer & supplier of wires and wire mesh,is a large-scale professional Galvanized Iron Wire factory in China. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world. Different kinds of wires and mesh are available according to customer’s requirements.

②What is your Technical Information of Hot Dipped Binding Wire 0.1mm to 6.0mm 0.2kg to 500kg/Roll Factory Price?

1).Material: super carbon steel

2).Processing by drawing, hot-dip zinc-plating

3).Standard wire gauge from 8# to 24#

4).Thick zinc-coating layer

5).Super in corrosion resistance

6).Firm coating layer

7).Custom size available

③How long can we receive the product after payment?

In the purchase of Galvanized Iron Wire within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: wire diagram and manual

- a small boats wiring cant be very complicated. If you're needing to replace it get a book called Small Boat Wiring or a similar. If you're trying to find a fault with existing wiring simply trace the existing wires remake all the connections as you go. I suggest you pull the lot out redo it properly. Except for the electric start you dont need super heavy cabling for a small boat. Tinned multi strand wire with a core diameter of about 2 mm is fine. Get a roll of red one of black ( or use red/black figure 8 cable) From the battery fit a service fuse of about 15 - 20 amp in line with the positive cable right near the battery. Use only properly crimped screwed or soldered connections. If the connection is ever likely to get wet then cover the connection with a piece of heatshrink tubing with a good smear of neutral cure silicone inside it. The silicone should squeeze out both ends of the tube when you shrink it. Dont make any joints mid run ( never in the bilges). Make sure the wiring is secured where it is out of the way is neat. Support the wire near the connections. Run from the switch panel to each item as a separate circuit, dont daisy chain. Give each item its own cable including the return (black wire) brought back to the panel. Be neat make a permanent record of what you've done. Fuse each circuit with a fuse rated about 50% above what that item should draw. Always carry plenty of spare fuses.

- Q: I was doing some homemade circuit wiring and had a plug wired to a push button switch, wired to the load,(lamp light) then wired back to the plug. My question is the first time around I used 14g wire and it worked fine, light came on at the push button. Second time I used the same plug, 16gauge wire wired to the switch, to the load(this time a miniature bulb that sat in a smaller version of those pull lights in closets) and then back to the plug. When it was switched on nothing happened. So I went back to the 16gauge and wired it up and the bulb popped. Is this because the wire used is to small and not rated to carry the amps provided by the wall receptacle?

- Not sure, but I think you used a 12 V bulb instead of a 110V.

- Q: I want to get an underground fence but i cant figure out what the difference in the wire they use and regular insullated wire. What is the difference and why can't i use regular wire instead of the wire that comes with the kit

- The okorder

- Q: DO i TWIST THE WHITE AND RED SMALL WIRES TOGETHER UNDER THE WIRE NUTS ON AC WIRING TO THE CONDENSER?

- Do you have two whites and two reds? If so connect the whites together, and connect the reds together.

- Q: Some states allow the use of aluminum wire in houses in place of copper. If you wanted the resistance of your aluminum wire to be the same as that of copper, would the aluminum wire have to have a greater diameter than, smaller diameter than, of the same diameter as the copper wire? Calculate the thickness ratio of aluminum to that of copper.

- Are you using 12 volt batteries to do this..?

- Q: Hi I have a ceiling fan/light to put up but after taking down the original rose, I am now unsure how to wire the existing wiring into the ceiling fan the wiring is a s follows:block 1 Live empty,red,red, block 2 loop all empty, block 3 neutral empty,black,blackthe connections on the fan are live neutral and earthGrateful for any help

- Don't hurt yourself...Get someone with a volt meter to help you find which wire it what

- Q: I'm trying to fix a light fixture for a friend. Her father-in-law gummed it up. At the fixture, there are 3 white wires soldered to a single wire. There are 3 black individual wires and one red wire. There are three switches that control the light.If I hook one of the black and the 3 white to the light, the light stays on constantly. If I hook either of the two other black individually, nothing comes on period.I'm pretty much at a loss. Any advice would be greatly appreciated.

- USA Sounds to me that what you have is 1 two conductor (black/white) cable as a power feed, 1 two conductor tap taking power somewhere else, and 1 three conductor (black, white, red) taking power to and back from a switch. All the whites get joined together, with a pigtail to the light. Make sure you have a tester. Find the black wire that is always energized, and mark it. Find the black and red that are in the same cable; mark them. I think what you have is they ran power to the light instead of the switch, then took the power down to the switch on the black conductor, and back from the switch to the light on the red conductor. Take the black that is always hot, and splice it to the other two blacks. Do not take it to the light. Hook the red to the light. If this does not work, reverse the red and black that go to the switch. This will take power to the switch on the red, and back from the switch on the black.

- Q: My light switch has three sets of three wires (like conduit).. there are three black wires, three white wires, and three bare wires.. and I don't know how to hook up another light switch because it's near impossible to get three wires around a screw terminal. My boyfriend (works in maintenance) hooked a light switch up (one that you put the wires in a hole and then screw) except for the bare wire where two wires are under the screw terminal and the third is wrapped around the other two bare wires. The lights will stay on but when you turn the switch off, it kicks the breaker.. can anyone tell me why it's doing that? Thank you.

- What it sounds like is happening there is that the switch box is the main feed for the room. You have a set from the panel, a set for the light fixture, and a set that are downstream, such as for an outlet. You need to determine which set is which. Then cut a piece of black wire and a bare copper about 8 long. This is how the connections are made: TURN THE POWER OFF. Then connect all of the whites together with a wire nut. Connect the new bare copper to the other grounds with another wire nut. Then connect the black from the panel, the downstream black, and the short black together with another wire nut. The black to the light fixture and the black pigtail (short wire) connect to the 2 brass terminals on the switch. The bare copper pigtail goes on the green screw on the switch. Reinstall the switch in the box, turn the power on, and check your work. If the light stays on at all times, but the outlets only work when the switch is on, those 2 wires are reversed. Turn the power off, switch the wires, and you should be good to go. Hope this helps.

- Q: im gettin a amp and sub for my car and was wondering how would i make a wiring kit for it ... i have basic knolage of wires but thats about it thanks in advance

- the wiring kit is usually: - low gauge cable of certain length (x2) - rca cable of a certain length (x1) - small power connect cable (x1) seeing as these things are already pretty much in their simplest form, I don't see the practicality of making your own wiring kit. just buy one.

- Q: A vertical straight wire carrying an upward 14.2 A current exerts an attractive force per unit length of 7.80E-4 N/m on a second parallel wire 7.60 cm away. What is the magnitude of the current that flows in the second wire?

- For a current I1 = 14.2 Amperes and radial separation between wires r =0.076 m, the magnetic field at wire 2 is B =0.000037368 Tesla If current I2 = 21 Amperes then the force per meter is F/ΔL =0.000784 Newtons/m hyperphysics.phy-astr.gsu.edu/hba... Goodbye

Send your message to us

Hot Dipped Binding Wire 0.1mm to 6.0mm 0.2kg to 500kg/Roll Factory Price

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 250000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords