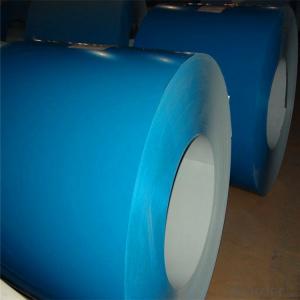

Hot Dipped Aluzinc Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

AZ60 (60G/㎡), Regular Spangle, Anti-Finger PrintFOB CY SHANGHAI (USD/MT)COIL ID: 508MMWEIGHT WIDTH OF ROLL THICKNESS- 75 ton 122 cm 0.58mm 710- 25 ton 120 cm 0.58mm 715- 50 ton 89 cm 1 mm 725- 25 ton 100 cm 1 mm 695COIL WEIGHT: ABOUT 5MTSPAYMENT: 30% T/T DOWNPAYMENT AND BALANCE AGAINST INVOICE & PACKING LIST OR 100% LC AT SIGHTCARGO READINESS: 35 DAYS AFTER T/T DOWNPAYMENT OR LC ISSUING DATESHIPMENT: BY 20’GP CONTAINER

- Q: What are the different types of steel coil storage systems?

- There are several different types of steel coil storage systems, including coil racks, coil cradles, coil saddles, and coil tongs.

- Q: How are steel coils used in the manufacturing of steel drums?

- Steel coils are used in the manufacturing of steel drums by being shaped and welded into the cylindrical body of the drum. The coils are unrolled and cut to the desired length, then formed into a circular shape and welded together to create a seamless drum.

- Q: Can steel coils be coated with tin?

- Yes, steel coils can be coated with tin.

- Q: How are steel coils used in the production of industrial machinery?

- Steel coils are used in the production of industrial machinery as they can be processed and shaped into various components such as structural supports, frames, and gears. The coils are often cut, bent, and welded to create the necessary parts that form the foundation of the machinery, ensuring strength, durability, and efficient operation.

- Q: How are steel coils used in the manufacturing of industrial mixers?

- Steel coils are often used in the manufacturing of industrial mixers as they provide the necessary strength and durability required for the equipment. These coils are typically used to construct the main body and components of the mixers, ensuring they can withstand the high-intensity mixing processes and heavy loads that they encounter in industrial settings.

- Q: I know you can still but steel core ammo. I have read that it IS Armor Piercing (AP) and I have read it is not. Which is true? I am not looking for its AP capabilities. I want it if it is or is not AP. I live in Oklahoma. I need to know if it legal for me to purchase it in this state; and where can i get it? I am over 18, not a felon, etc. I have seen it sold online in Oklahoma years ago, but have read it is and isn't legal to purchase here. I am looking for 7.62x39 steel core for an SKS. If anyone knows where or how to get some, please let me know, if it's legal. Thanks.

- You can legally buy chinese steel core and 855 5.56 which is also steel core. That's on the federal level. I don't know about your state in particular but ammo peircing ammo is illegal but there are different grades of steel. If that were the case I couldn't buy Bugarian steel cased light ball in 7.62x54R.

- Q: How do steel coils contribute to energy savings in buildings?

- Steel coils contribute to energy savings in buildings in several ways. Firstly, steel coils are often used as part of the insulation system in buildings. The high thermal conductivity of steel allows for efficient heat transfer, ensuring that the building remains well-insulated and energy loss is minimized. Additionally, steel coils are often used for HVAC systems, which play a crucial role in energy efficiency. By using steel coils in these systems, the heat transfer process can be optimized, reducing the energy required to heat or cool the building. Moreover, steel coils are durable and long-lasting, reducing the need for frequent replacements and maintenance, which in turn saves energy and resources. Overall, the use of steel coils in buildings helps to improve energy efficiency and reduce energy consumption, contributing to significant energy savings.

- Q: What are the different types of steel coil surface protection methods?

- There are several types of steel coil surface protection methods, including oiling, painting, galvanizing, and applying protective films. These methods help prevent corrosion, rusting, and damage to the steel surface during storage, transportation, and processing.

- Q: What is the average flatness tolerance for steel coils?

- The average flatness tolerance for steel coils varies depending on the specific industry and application. However, in general, most steel coil manufacturers aim for a flatness tolerance of around 0.25% to 0.5% of the material's thickness.

- Q: How are steel coils packaged for shipping?

- Steel coils are typically packaged for shipping by being tightly wound and secured with steel bands or straps. They are then placed on wooden pallets or in steel cradles to ensure stability during transportation. Additionally, protective packaging materials such as plastic or cardboard may be used to prevent damage from moisture, dust, or other external factors.

Send your message to us

Hot Dipped Aluzinc Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords