Hot-dip Aluzinc Steel Coil with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-Dip Aluzinc Steel Coil Used for Industry

1.Structure of Hot-Dip Aluzinc Steel Coil Description

Hot-dip aluzinc steel sheet is substrated on cold rolled steel in various strength and specification. Coating composition is 55% aluminmum in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent and heat resistance performance.

2.Main Features of the Hot-Dip Aluzinc Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

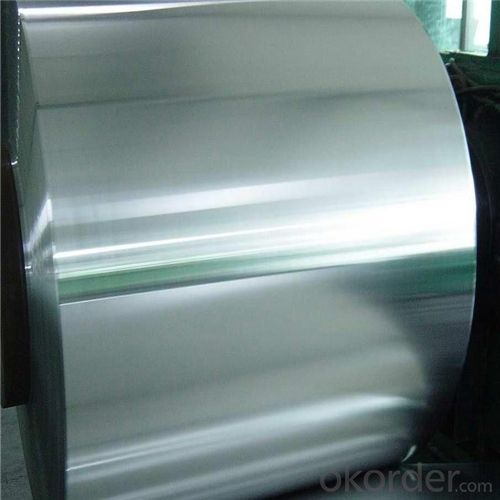

3. Hot-Dip Aluzinc Steel Coil Images

4. Hot-Dip Aluzinc Steel Coil Specification

Hot-Dip Aluzinc Steel Coil | |

Thicknenss | 0.16mm-3.5mm |

Width | 1250mm max |

Coating mass | 30-185g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How are steel coils processed and shaped into specific products?

- Steel coils are processed and shaped into specific products through a series of steps, involving various machinery and techniques. The process begins with the steel coils being unwound and flattened using a decoiler and a leveller. This step ensures that the coils are ready for further processing. Next, the flattened coils are fed into a rolling mill, where they undergo a process called cold rolling. Cold rolling involves passing the coils through a series of rollers to reduce their thickness and improve their surface finish. This process also enhances the strength and hardness of the steel. After cold rolling, the steel coils may undergo additional processes such as annealing or galvanizing, depending on the desired properties of the final product. Annealing involves heating the coils to a specific temperature and then slowly cooling them, which helps to relieve internal stresses and improve the steel's ductility. Galvanizing, on the other hand, involves coating the coils with a layer of zinc to protect them from corrosion. Once the necessary treatments are completed, the steel coils are ready to be shaped into specific products. This is achieved through various methods such as cutting, stamping, or forming. Cutting involves using shears or lasers to trim the coils into specific sizes or lengths. Stamping involves using a die and a press to shape the coils into intricate designs or patterns. Forming, on the other hand, involves bending or shaping the coils using specialized machinery to create curved or contoured products. Finally, the shaped steel products are inspected for quality and undergo any necessary finishing processes such as painting or coating. This ensures that the products meet the required specifications and are ready for distribution or further assembly. In summary, steel coils are processed and shaped into specific products through a combination of steps including unwinding, flattening, cold rolling, annealing or galvanizing, cutting, stamping, forming, inspection, and finishing. Each of these steps plays a crucial role in transforming the raw steel coils into high-quality products used in various industries.

- Q: How are steel coils used in the oil and gas industry?

- Steel coils are commonly used in the oil and gas industry for various purposes such as manufacturing pipelines, storage tanks, and offshore platforms. These coils are formed into cylindrical shapes and serve as the main structural component for these applications, providing strength, durability, and resistance to extreme conditions. Additionally, steel coils are used in the production of equipment like heat exchangers, compressors, and drilling machinery, which are essential for the extraction, processing, and transportation of oil and gas.

- Q: What are the different types of welding used for steel coils?

- There are several different types of welding used for steel coils, depending on the specific requirements and applications. Here are some of the most common types of welding techniques used for steel coil fabrication: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, it involves the use of a flux-coated electrode and an electric current to create an arc between the electrode and the base material. SMAW is a versatile and widely used welding technique suitable for various steel coil applications. 2. Gas Metal Arc Welding (GMAW): Commonly known as MIG (Metal Inert Gas) welding, GMAW uses a continuous wire electrode and a shielding gas to protect the weld pool from atmospheric contamination. GMAW is known for its high welding speed and ease of automation, making it a popular choice for steel coil manufacturing. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW uses a tubular electrode with flux inside. The flux provides both the shielding gas and additional alloying elements, resulting in increased efficiency and improved weld quality. FCAW is often used in high-speed welding applications for steel coils. 4. Gas Tungsten Arc Welding (GTAW): Also known as TIG (Tungsten Inert Gas) welding, GTAW uses a non-consumable tungsten electrode and an inert gas, typically argon, to shield the weld area. GTAW produces high-quality, precise welds with excellent control over the heat input, making it suitable for thin steel coil materials and critical welding applications. 5. Submerged Arc Welding (SAW): This welding technique involves the use of a continuously fed wire electrode and a granular flux that covers the weld area. The arc is submerged under the flux, providing excellent protection and reducing the need for post-weld cleaning. SAW is commonly used for welding thick steel coils due to its high deposition rates and deep penetration capabilities. These are just a few examples of the different types of welding techniques used for steel coil fabrication. The choice of welding method depends on factors such as the specific steel grade, thickness, desired weld quality, production speed, and cost considerations. It is essential to select the appropriate welding technique to ensure the durability and performance of the steel coils in various applications.

- Q: I bought a stainless steel water bottle today. I really like it, but there is no drinking spout, it just has a lid that screws on and off, and an open hole to fill it and drink out of. Is this normal for these bottles? Or do they usually come with a spout to drink from? I don't want to look like an idiot at the gym drinking from this cool bottle with no spout if there's supposed to be one! haha.

- That's normal. I'm sure there are caps that you can get that have a built in spout though.

- Q: Fallout 3 take it back quest?if i am in the rotunda and dont have broken steel installed yet so i cant leave if i instal it will i be able to continue the game even if im seconds away from the end without it Additional Detailsi know it continues on but im not sure if it will let me cause i got this far without it 1 objective away from finishing the quest idk if it will change that little bit so i can continue (ps3)already in the purifier place kill col. autum liek i said just gotta do the code thing to it idk if im to far for broken steel to effect this save file

- Yes. The Broken Steel add-on goes automatically where ever you are. The thing is, I would like stand around the control room for a little while until the Broken Steel add-on is completely downloaded (Basically pop A LOT of rad-x and radaway). You should see a pop-up message saying that Broken Steel is installed and the level cap is now at 30.

- Q: How do steel coils contribute to the automotive manufacturing sector?

- Steel coils are essential in the automotive manufacturing sector as they are used to produce various components such as body parts, frames, and suspension systems. The high strength and durability of steel coils make them ideal for ensuring the safety and structural integrity of vehicles. Additionally, steel coils are easily moldable, allowing manufacturers to create complex shapes and designs, contributing to the overall aesthetics and functionality of automobiles.

- Q: What are the common coil slitting methods?

- The common coil slitting methods include rotary shear slitting, loop slitting, and single-knife slitting.

- Q: I was wondering if anyone knew the grade/type of steel for this product. I'd like to use it as stock for a knife blade, but would like to know the specs so I can determine if it is suitable and, if so, how best to heat treat it.Thanks.PS: I know it isn't stainless, but that leaves a lot of other steel types.

- Flat Steel Bar

- Q: Are steel coils corrosion-resistant?

- Yes, steel coils can be corrosion-resistant depending on the type of steel used and any additional protective coatings applied.

- Q: I need to know a name of any site which provides information on Steel structures??

- steel structure- TC bolt to connect,SG shear wrench

Send your message to us

Hot-dip Aluzinc Steel Coil with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords