Horizontal Multistage Booster Water Pump for Boiler Feed

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Horizontal Multistage Booster Water Pump for Boiler Feed

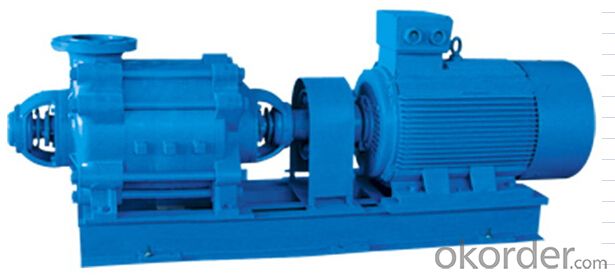

1.Structure of Horizontal Multistage Booster Water Pump for Boiler Feed

The high presuure boiler feed multistage water pump is a horizontal multistage centrifugal pump and suitable for transporting pure water,both ends of it are supported,the casing portion is a senctional form,it is connected and actuated by motor via a resilient clutch.From the driven direction,the pump rotated direction is clockwise.

2.Main Features of Horizontal Multistage Booster Water Pump for Boiler Feed

• High Effiency

•Low noise

•Long life, OEM and ODM are welcomed.

3.Horizontal Multistage Booster Water Pump for Boiler Feed Images

4.Horizontal Multistage Booster Water Pump for Boiler Feed Specification

Material |

Cast iron and as customer's request |

Temperature |

Less than 150°C |

Flow rate | 3.75-300m3/h |

Head | 75-1000m |

Medium temperature | 0 ~170°C |

Operation pressure | ≤40 bars |

5.FAQ

①What is the applications?

Power Station,Industry Water Supply

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance. Normally, We have 1 year warranty.

- Q: Rotary vacuum pump does not meet the requirements of vacuum, what are the reasons?

- 1) oil rotary vane vacuum pump is too low, no effect on the oil seal exhaust valve, rotary plug to refuel after large exhaust sound, and oil mist, that the level is too low, the gas can be eliminated.(2) the vacuum caused by the condensable steam pollution of oil should be changed, and new vacuum pump oil should be replaced.

- Q: Must the water pump in the tank be all soaked in water?

- Need a submersible pump in the water, but it is not entirely like this, I have to work for a long time no problem in water, but there is a problem you should pay attention to the water pump, at least in half, or stop when the smoke is not on water.

- Q: Is the diaphragm pump and the drain pump one?

- Therefore, the need to play a liquid discharge pump, if the medium is corrosive liquid, high viscosity, volatile, flammable, highly toxic liquid, you can choose diaphragm pump. Conversely, the general liquid, there is no special requirements, you can use the general centrifugal pump to reduce costs.

- Q: How to distinguish the flow and displacement in the hydraulic pump? What's the difference between the two?

- For example, once you sprinkle water from the tank to the ground, one shot of water is 1000 milliliters, which is equivalent to displacement, once (pump turn) 1000 ml.,

- Q: Please give me professionals to calculate, the cylinder bore is 100 and the rate of 20m/s, the leakage can be ignored, but to the large flow pump!

- 1. rpmOperating speed is the actual rotation speed of a pump (or motor) at work.Rated speed is the maximum speed that can operate normally for a long time under rated pressure. If the pump exceeds the rated speed, the work will cause insufficient oil absorption, vibration and noise, the parts will suffer cavitation damage, life expectancy.Minimum steady speed is the minimum speed allowed for normal motor operation. At this speed, the motor does not appear crawling phenomenon.

- Q: What is the liquid pump? What are their categories? What are their strengths and weaknesses?

- The liquid pump can be filled with oil, water and chemical medium. The gas drive range of the liquid pump is 1 to 10bar (14.5-145psi). The bottom piston is controlled by a two position four pass pilot valve.

- Q: What are the problems that should be paid attention to when using vacuum pumps?

- (8) in the process of running the pump, the bearing temperature shall not exceed the ambient temperature 35C, and the maximum temperature shall not exceed 80C.(9) if the abnormal sound of the vacuum pump is found, the reason should be stopped immediately.(10) vacuum pump to stop using, first shut down valve, pressure gauge, and then stop the motor. (11) vacuum pump in the first month of work, 100 hours after the replacement of lubricating oil, oil every 500 hours after the change.(12) adjust packing gland regularly to ensure the normal condition of drip in packing room. (13) regular inspection of shaft sleeve wear, larger wear should be replaced in good time.

- Q: Common failure treatment of piston pump

- 1) overflow valve regulation is too high, overload after the pump2) the overflow valve spool is blocked, the central hole of the valve core is blocked or the overflow valve is blocked by a damping hole, and the overflow is not overflow3) pump outlet one-way valve installed or spool blocked and stuffy pump4) motor fault x091) adjust the relief valve pressure value2) repair valve boring3) overhaul check valve4) overhaul or replace the motor

- Q: Metering pumps related matters

- 2) change the metering pump diaphragmTrouble is often encountered when the old diaphragm is removed. Provide some additional advice on how to remove the old diaphragm.After in the pump head loose, remove the pump head before the stroke length adjustment to the 10% position. To ensure that the electromagnetic axis has sufficient pressure to maintain its connection firmly, so that you can unscrew the diaphragm.The pull end torque from the Jack out of the screw. Seize the liquid counter clockwise rotation. There is a slight resistance that can unscrew the diaphragm.Chemical 3 measurement may end in fluid crystallization, resulting in a one-way valve ball and seat valve does not work.In the end inhalation metering pump may have a gas leak. Hydraulic end suction side connector may lack O ring or suction valve connection loose.3) flow monitoring and measurement of a high viscosity medium, in the process of liquid delivery received a flow failure signal, how can we solve this problem?Move the hydraulic end by loosening the 4 pump head screws. Rotating stroke length to 10%, and seize the hydraulic end, and then slide out of the screw hole, then the screws do not touch them, but still control the back and diaphragm. Then rotate the component counter clockwise, with a slight resistance, and the diaphragm will loosen from the electromagnetic axis. If the diaphragm is not loose, use some grease on the contact surfaces of the diaphragm and the electromagnetic shaft. After a few minutes, gently tap the diaphragm with a small plastic hammer. Then proceed again in accordance with the above description.

- Q: Centrifugal pumps for normal operation, is it reasonable to install valves on their inlet lines? Why?

- Unreasonable, easy to produce throttling loss, pressure loss, pressure reduction, easy to cause cavitation

Send your message to us

Horizontal Multistage Booster Water Pump for Boiler Feed

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords