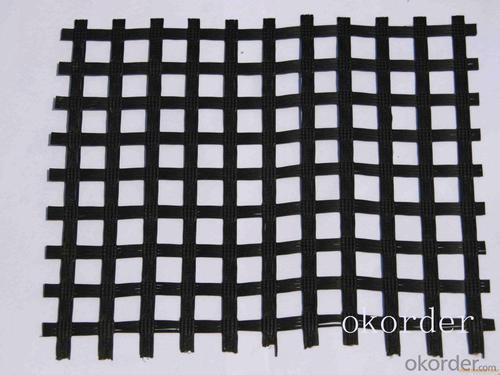

Hanes High Strength Fiberglass Geogrids for Civil Engineering Construction - Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

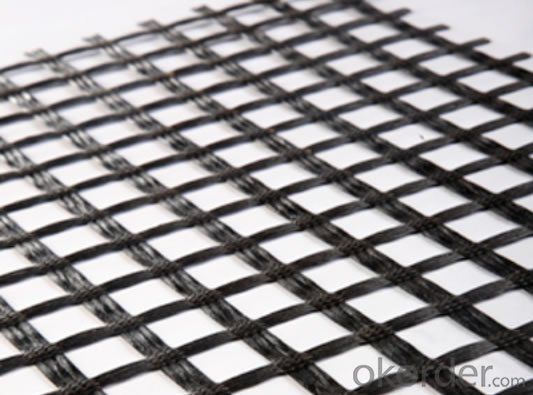

Plastic Geogrid is drilling a hole in the polymer board, by cold-drawn, the shape with large holes(long hole or square hole) of the high strength reinforcement material. According to customer demand, could composite geotextile or other material.

CNBM offers BaseGrid biaxial geogrids for base reinforcement. They are manufactured by welding or stitching together two layers of extruded, polypropylene, flexible geogrids to create a continuous sheet that will not separate.

Main applications:

Road bed reinforcement-it can effectively allocate and disperse load,improve the stability and load capacity of road bed and extend the useful lfe of road

It can be withstand greater alternating load

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

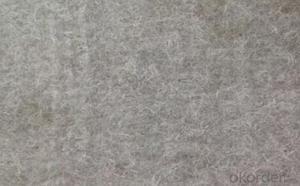

A: Yes, please check the pictures:

- Q: What is the coefficient of friction of Nonwoven Geotextiles (polypropylene)?

- The biggest difference is that the geotextile with the membrane is impermeable and the nonwoven geotextile is permeable

- Q: Can geogrids be used in temporary construction access mats?

- Yes, geogrids can be used in temporary construction access mats. Geogrids are commonly used to improve the stability and load-bearing capacity of access mats, making them suitable for temporary construction sites. They help distribute the weight of heavy equipment and vehicles and prevent soil erosion, ensuring safe and efficient access for construction activities.

- Q: How do geogrids improve the stability of cut slopes?

- Geogrids improve the stability of cut slopes by providing reinforcement to the soil, preventing it from sliding or slumping. These grid-like structures are placed within the soil layers, distributing the forces exerted by the slope and increasing its overall strength. Additionally, geogrids enhance the soil's ability to withstand erosion, maintain its integrity, and prevent the formation of cracks.

- Q: Can geogrids be used in coastal erosion control projects?

- Yes, geogrids can be used in coastal erosion control projects. Geogrids are commonly used in these projects to stabilize and reinforce coastal slopes, preventing erosion and maintaining the integrity of the coastline. They can help to reduce wave energy and control sediment movement, making them an effective solution for coastal erosion control.

- Q: How do geogrids improve the performance of geocell-reinforced embankments?

- Geogrids improve the performance of geocell-reinforced embankments by providing additional tensile strength and stability to the structure. They enhance the load-bearing capacity of the embankment, preventing lateral spreading and soil erosion. Geogrids also distribute the applied loads more evenly, reducing the stress on the geocell walls and maintaining the integrity of the structure. Overall, geogrids enhance the overall performance, longevity, and safety of geocell-reinforced embankments.

- Q: Can geogrids be used in retaining wall facing systems?

- Yes, geogrids can be used in retaining wall facing systems. Geogrids are commonly used to reinforce and stabilize soil in retaining walls, and they can help enhance the overall strength and stability of the wall. They are typically placed within the soil layers behind the facing system to distribute the forces and prevent excessive movement or failure of the retaining wall.

- Q: How do geogrids help in reducing the risk of landslides?

- Geogrids help in reducing the risk of landslides by reinforcing the soil and increasing its stability. They are typically placed in the ground to provide additional strength and prevent soil movement, effectively distributing the forces acting on the slope. This reinforcement helps to resist the gravitational pull that can cause landslides, reducing the likelihood of slope failure and subsequent damage.

- Q: What is the effect of strain rate on geogrid behavior?

- The effect of strain rate on geogrid behavior is that it influences the mechanical properties and performance of the geogrid material. Higher strain rates typically result in increased stiffness and strength, as well as reduced deformation and creep behavior. This is due to the time-dependent nature of geogrids, where faster loading rates induce a more immediate response from the material. Therefore, understanding and accounting for strain rate effects is crucial in designing and predicting the behavior of geogrids in various engineering applications.

- Q: Are geogrids suitable for erosion control on riverbanks?

- Yes, geogrids are suitable for erosion control on riverbanks. Geogrids provide stabilization and reinforcement to the soil, preventing erosion and maintaining the integrity of the riverbank. They are effective in withstanding the forces of water flow and offer long-term stability, making them an ideal solution for erosion control on riverbanks.

- Q: How to determine geogrid reinforcement or crack resistance

- Highway such as half fill half dug, soft foundation zone to prevent the differential settlement, fill inspection batch to distinguish between, please know that. Thank you

Send your message to us

Hanes High Strength Fiberglass Geogrids for Civil Engineering Construction - Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords