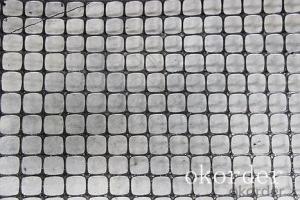

High Modulus Fiberglass Geogrid with High Tensile Strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

Biaxial

Production function

1.It can be applied in all kinds of roads,airports to enhance the roadbed;

2.It can be applied in a large car park and terminal freight yard,etc. to strengthen the foundations of a permanent load;

3.It can be applied in rail, road slope's protection;

4.It can be applied to enhance the culvert;

5.It can be applied as a secondary enhancement after the uniaxial Geogrid soil enhancement, further enhance the soil;

6.It can be applied in mining, tunnel reinforcement.

7.Network used for animal and husbandry;

8.Network used for cage fishing.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Evaluation criteria and technical disclosure of geogrid.. Know how to share. Thank you

- 2) according to the design of the location, along the road to the laying of the grid, laying the grille, should pay attention to the connection between the grid and straightening smooth. Grille of the longitudinal and transverse joints can use nylon or polyester rope sewn or U nail connection method between the grid as a whole, grid overlapping width not less than 20cm, in the direction of the stress intensity of the joint shall not be less than the design tensile strength of materials. The grid distortion, fold, overlap, is not conducive to play its role, thus laying by hands straightened, the grid is smooth and uniform, geogrid every 1.5-2.0m paved with hook nail fixed on the ground.

- Q:How do geogrids improve the performance of flexible bridge abutments?

- Geogrids improve the performance of flexible bridge abutments by providing reinforcement and stabilization to the soil. These synthetic materials are placed within the backfill soil behind the abutment, increasing its strength and load-bearing capacity. Geogrids also help distribute the load more evenly, reducing stress and potential settlement. This reinforcement prevents excessive movement and settlement of the abutment, ensuring its stability and longevity.

- Q:Are geogrids suitable for use in soft soil conditions?

- Yes, geogrids are suitable for use in soft soil conditions. Geogrids are engineered materials that provide reinforcement and stabilization to soils. They are specifically designed to improve the strength and stability of weak or soft soils. By distributing the loads and reducing soil movement, geogrids can effectively enhance the performance of the soil, making them a suitable solution for soft soil conditions.

- Q:Can geogrids be used in geothermal energy systems?

- Yes, geogrids can be used in geothermal energy systems. Geogrids are often used to reinforce soil structures and provide stability, which can be beneficial in supporting the infrastructure and components of geothermal energy systems. They can help prevent soil erosion, provide load-bearing capacity, and enhance the overall performance and longevity of the system.

- Q:Do geogrids help in reducing soil erosion?

- Yes, geogrids can help in reducing soil erosion. Geogrids are synthetic materials that are installed in soil to reinforce it and provide stability. They act as a barrier that prevents soil particles from being washed away by water or blown away by wind, thereby reducing erosion.

- Q:What are the factors to consider when selecting geogrids for a project?

- When selecting geogrids for a project, there are several factors to consider. These include the specific application or purpose of the project, the site conditions such as soil type and slope stability, the load requirements of the project, the desired lifespan and durability of the geogrids, and the cost-effectiveness and availability of the geogrids. Additionally, it is important to consider the installation process and compatibility with other materials used in the project. By considering these factors, you can ensure that the selected geogrids will effectively meet the needs of your project.

- Q:What is the effect of confinement on geogrid performance?

- The effect of confinement on geogrid performance is generally positive. Confinement helps improve the stability and load-bearing capacity of geogrids by restraining lateral movement and enhancing soil-geogrid interaction. It prevents the geogrid from elongating or deforming under heavy loads, leading to better reinforcement and increased structural integrity. Confinement also reduces the potential for geogrids to slip or creep, improving their long-term performance and durability.

- Q:Can geogrids be used in stormwater management?

- Yes, geogrids can be used in stormwater management. Geogrids are often employed in stormwater management systems to reinforce soil and stabilize surfaces, such as retaining walls, slopes, and embankments. They help prevent soil erosion, enhance drainage, and improve the overall performance and longevity of stormwater management infrastructure.

- Q:What are the factors that affect the installation and survivability of geogrids in cold climates?

- There are several factors that can influence the installation and survivability of geogrids in cold climates. Firstly, the freezing and thawing cycles in cold climates can result in ground movement, which may impact the stability and performance of geogrids. Additionally, the presence of frost heave can cause uplift forces on the geogrids, potentially leading to damage or failure. The type and quality of the soil, as well as its moisture content, also play a crucial role in determining the effectiveness of geogrid installation in cold climates. Furthermore, the design and proper installation techniques, such as adequate anchoring and appropriate subgrade preparation, are essential for ensuring the long-term survivability of geogrids in cold climates. Overall, understanding and addressing these factors are vital to ensure the successful implementation of geogrids in cold climate regions.

- Q:Can geogrids be used in shoreline protection applications?

- Yes, geogrids can be used in shoreline protection applications. Geogrids are commonly used in erosion control projects, including shoreline protection, to reinforce soil and prevent erosion. They can help stabilize the shoreline, reduce wave impact, and provide long-term protection against erosion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Modulus Fiberglass Geogrid with High Tensile Strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords