FRP Pultrusion Profiles - High Strength, Corrosion Resistant, and Fire Resistant for Platform with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

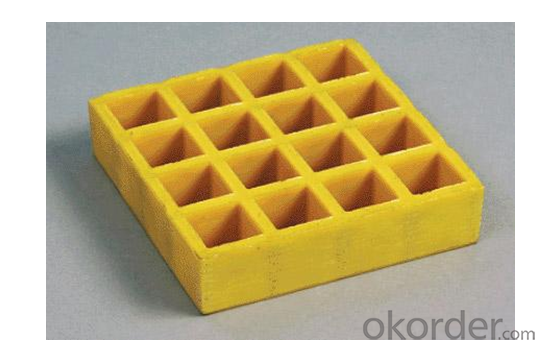

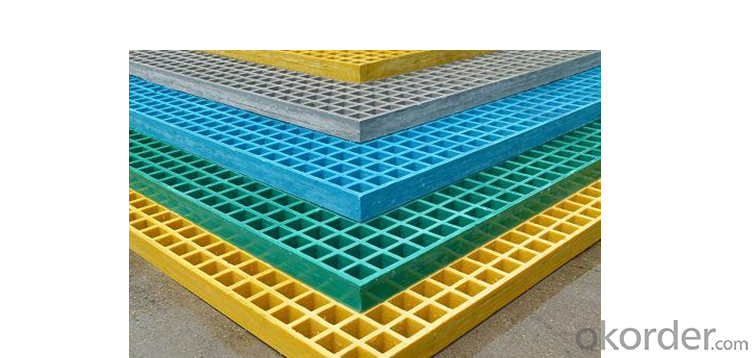

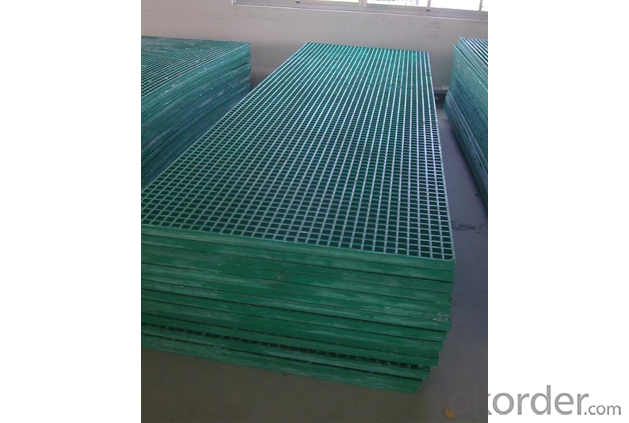

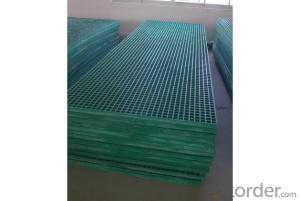

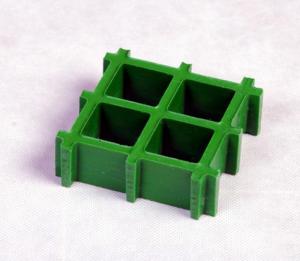

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Aging Resistance

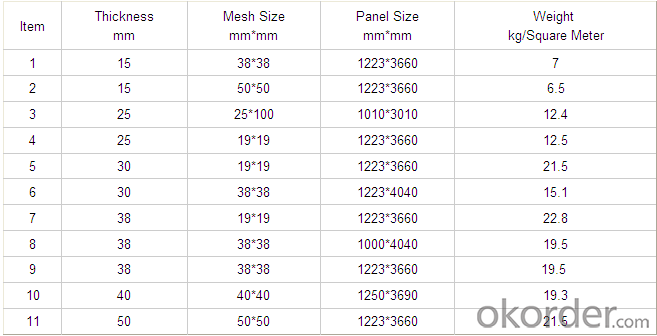

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

- FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

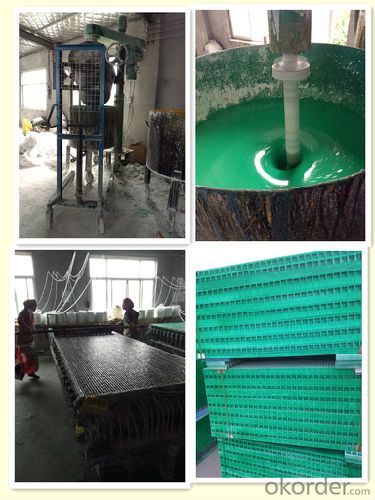

FACTORY

- Q: Are FRP pultrusion profiles resistant to impact from heavy machinery?

- FRP pultrusion profiles are generally known for their high strength-to-weight ratio and excellent mechanical properties, which make them resistant to various external impacts. However, the specific resistance to impact from heavy machinery depends on several factors. Firstly, the design and composition of the FRP pultrusion profiles play a vital role in determining their impact resistance. Different manufacturers may use various reinforcement materials, such as fiberglass, carbon fiber, or other composites, which can significantly affect the profiles' ability to withstand heavy machinery impacts. Additionally, the thickness and overall dimensions of the FRP profiles contribute to their impact resistance. Thicker profiles tend to provide higher resistance to impact loads compared to thinner ones. Moreover, profiles with reinforced sections or additional layers for structural integrity can further enhance their impact resistance. It is also essential to consider the specific application and the magnitude of impact expected from heavy machinery. While FRP pultrusion profiles can generally withstand moderate to high impacts, extreme forces or heavy machinery with substantial weight may still cause damage. In such cases, additional protective measures like using impact-resistant coatings or reinforcing the profiles with metal inserts may be necessary. Overall, FRP pultrusion profiles exhibit good resistance to impact from heavy machinery due to their inherent strength and durability. However, it is always recommended to consult with the manufacturer or a structural engineer to ensure the profiles meet the specific requirements of the application and machinery involved.

- Q: Are FRP pultrusion profiles resistant to electrical arcing?

- Generally, FRP pultrusion profiles exhibit resistance to electrical arcing due to their composition of non-conductive materials such as fiberglass reinforced plastic. By not conducting electricity, these profiles prove to be an optimal choice when concerns arise regarding electrical arcing and conductivity. Nevertheless, it is crucial to acknowledge that the extent of their resistance to electrical arcing may differ based on the unique composition and design of the FRP pultrusion profiles. Therefore, it is advisable to consult the manufacturer or supplier of the profiles to ensure they meet the specific electrical resistance standards required for a given application.

- Q: Can FRP pultrusion profiles be used in the production of electrical cabinets?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the production of electrical cabinets. FRP pultrusion profiles provide excellent electrical insulation properties, high strength-to-weight ratio, and resistance to corrosion, making them suitable for use in electrical cabinets where electrical safety and durability are essential.

- Q: Are FRP Pultruded Shapes poisonous?

- The products certified by SGS are basically reliable.If the food is best to use food grade resin, there is a health permit.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of antenna masts?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of antenna masts. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and excellent electrical insulation properties. These characteristics make them ideal for antenna mast construction, as they can withstand various environmental conditions and provide reliable support for antennas.

- Q: Can FRP pultrusion profiles be used in renewable energy projects?

- Yes, FRP pultrusion profiles can be used in renewable energy projects. FRP (Fiber Reinforced Polymer) pultrusion profiles offer high strength, durability, and corrosion resistance, making them suitable for various applications in renewable energy projects. They can be used in the construction of wind turbine blades, solar panel frames, and structural supports for renewable energy infrastructure. Additionally, FRP pultrusion profiles can provide cost-effective solutions by reducing maintenance requirements and improving the overall performance of renewable energy systems.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of chemical reactors?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are suitable for the manufacturing of chemical reactors. FRP pultrusion profiles offer several advantages that make them well-suited for this application. Firstly, FRP pultrusion profiles are highly corrosion-resistant, which is a critical characteristic for chemical reactors that are exposed to harsh chemicals. Unlike traditional materials like steel or concrete, FRP does not corrode or degrade when exposed to a wide range of chemicals, making it a reliable choice for chemical reactor construction. Secondly, FRP pultrusion profiles are lightweight yet strong, providing excellent structural integrity and durability. This allows for the construction of large-scale chemical reactors without adding excessive weight, reducing installation and transportation costs. Furthermore, FRP pultrusion profiles offer design flexibility, allowing for customization to meet specific requirements. They can be easily molded into various shapes and sizes, enabling the construction of complex reactor designs that optimize efficiency and performance. In addition, FRP pultrusion profiles have excellent thermal insulation properties, which can be advantageous in maintaining stable operating temperatures within chemical reactors. This can help improve the overall energy efficiency of the reactor and reduce heat loss. Overall, FRP pultrusion profiles are suitable for the manufacturing of chemical reactors due to their corrosion resistance, lightweight yet strong nature, design flexibility, and thermal insulation properties. These profiles offer a reliable and cost-effective solution for constructing chemical reactors that can withstand the demanding conditions of chemical processing.

- Q: How to install GRP mark pile

- The first said the difference is not the same as the first material (FRP pultrusion is out of the square or triangle pipe by processing printing or engraving machine engraving to cover finished concrete (concrete) is the direct brush word OK)

- Q: How do FRP pultrusion profiles perform in high humidity environments?

- FRP (Fiber Reinforced Polymer) pultrusion profiles perform exceptionally well in high humidity environments. The inherent properties of FRP, such as its corrosion resistance and moisture resistance, make it an ideal material for applications that are exposed to moisture or high humidity. One of the key advantages of FRP pultrusion profiles is that they are non-porous, which means they do not absorb moisture. This characteristic prevents the profiles from swelling, warping, or rotting when exposed to high levels of humidity. Unlike traditional materials like wood or steel, FRP does not degrade or lose its structural integrity in humid conditions. Additionally, FRP pultrusion profiles have a high resistance to chemicals, including the corrosive effects of moisture and humidity. This resistance to corrosion is due to the composite nature of FRP, which combines a matrix material (typically a resin) with reinforcing fibers, such as glass or carbon fibers. This combination provides excellent resistance to water and moisture-induced corrosion, ensuring the long-term performance of FRP profiles in high humidity environments. Furthermore, FRP pultrusion profiles offer excellent dimensional stability, even under extreme temperature and humidity variations. They do not expand or contract significantly, maintaining their shape and structural integrity in diverse environmental conditions. This stability makes FRP profiles suitable for applications in coastal regions, wastewater treatment plants, chemical processing plants, and other environments where humidity levels are high. Overall, FRP pultrusion profiles are specifically engineered to withstand harsh conditions, including high humidity environments. Their non-porous nature, resistance to corrosion, and dimensional stability make them a reliable and durable choice for various applications in humid climates.

- Q: Can FRP pultrusion profiles be used in the construction of chemical storage tanks?

- FRP pultrusion profiles have the capability to be utilized in the construction of chemical storage tanks. Their exceptional resistance to corrosion is well-known, making them an optimal choice for storing a wide array of chemicals. Pultrusion profiles, created by pulling fiber reinforcements through a resin bath and then through a heated die, possess a high strength-to-weight ratio, dimensional stability, and durability. Most chemicals do not cause a reaction with FRP pultrusion profiles, and they can withstand harsh environments, including exposure to corrosive substances. The profiles have a low permeability, which prevents chemicals from seeping through the tank walls. Moreover, FRP profiles can be customized to meet specific requirements, enabling the construction of tanks in various shapes and sizes. In addition, FRP pultrusion profiles offer other benefits, such as easy installation, reduced maintenance, and a long service life. Being lightweight simplifies transportation and installation processes. The low maintenance requirements of FRP tanks contribute to minimizing downtime and reducing overall costs. With appropriate design and construction, FRP pultrusion profiles can provide reliable and long-lasting solutions for chemical storage tank applications.

Send your message to us

FRP Pultrusion Profiles - High Strength, Corrosion Resistant, and Fire Resistant for Platform with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords