FRP Pultrusion Profiles - Corrosion Resistant and Fire Resistant FRP Gratings with Modern Shape/Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

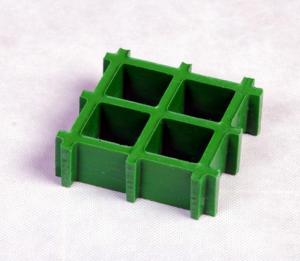

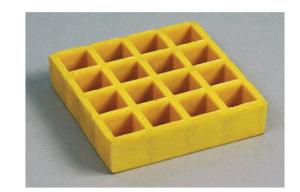

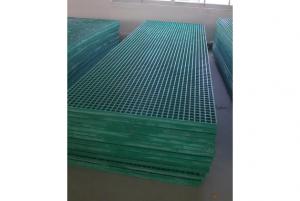

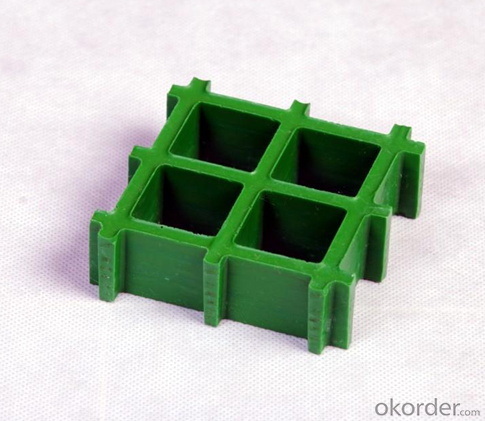

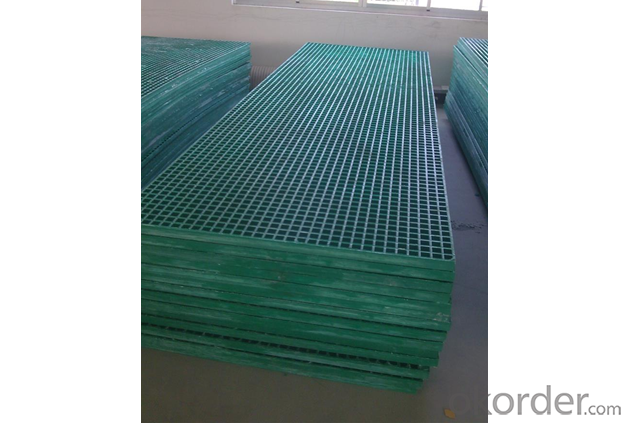

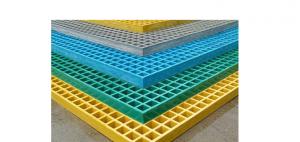

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

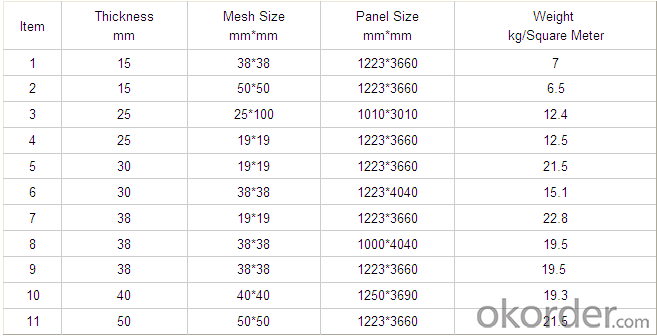

Specification

Advantage

- no maintenance

high strength

long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

- FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How is the package?

Usually, we arrange the standard out-package for exporting.

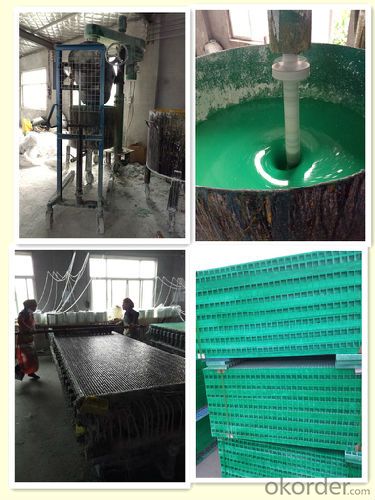

PROCESS

FACTORY

- Q: Can FRP pultrusion profiles be used in the construction of wind turbine blades?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of wind turbine blades. FRP pultrusion profiles offer several advantages that make them suitable for wind turbine blade construction. Firstly, FRP pultrusion profiles are lightweight yet strong, which is an important characteristic in wind turbine blades as they need to be able to withstand the aerodynamic forces exerted by the wind. The high strength-to-weight ratio of FRP pultrusion profiles allows for the construction of longer and more efficient blades. Additionally, FRP pultrusion profiles have excellent corrosion resistance properties, which is crucial for wind turbines exposed to harsh weather conditions. Unlike traditional materials like steel, FRP does not corrode, ensuring a longer service life for the wind turbine blades. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements. This flexibility allows for the optimization of blade performance by tailoring the shape, thickness, and stiffness of the profiles to maximize energy capture and minimize fatigue. Furthermore, FRP pultrusion profiles offer good fatigue resistance, meaning they can withstand repeated loading cycles without experiencing significant degradation in performance. This is essential for wind turbine blades that are subjected to cyclic loading due to wind gusts and changes in wind direction. Finally, FRP pultrusion profiles are also electrically non-conductive, which is advantageous for wind turbine blades as it eliminates the risk of electrical discharge during operation. Overall, the lightweight, strong, corrosion-resistant, and customizable nature of FRP pultrusion profiles make them an excellent choice for the construction of wind turbine blades, contributing to the development of more efficient and durable wind energy systems.

- Q: Can FRP pultrusion profiles be used in the construction of highway guardrails?

- Highway guardrails can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess several advantages that render them appropriate for this purpose. To begin with, FRP pultrusion profiles combine strength with a lightweight nature, making them ideal for highway guardrails. Their high strength-to-weight ratio enables them to provide the necessary structural support while being significantly lighter than conventional materials such as steel. This facilitates easier and more cost-effective transportation, installation, and maintenance. Moreover, FRP pultrusion profiles exhibit corrosion resistance, unlike steel, which is susceptible to rusting over time due to exposure to harsh weather conditions. The absence of corrosion in FRP guardrails ensures their durability and longevity, thereby reducing the frequency of repairs or replacements. In addition, FRP pultrusion profiles are non-conductive, meaning they do not conduct electricity. This feature is crucial for highway guardrails as it eliminates the risk of electrical shock in the event of accidents involving power lines or lightning strikes. Furthermore, FRP pultrusion profiles can be manufactured in various shapes and sizes to meet the specific requirements of highway guardrails. They can be designed to possess the necessary stiffness and impact resistance to withstand the forces exerted by vehicles during accidents or collisions. In conclusion, FRP pultrusion profiles offer a suitable material for constructing highway guardrails due to their lightweight, corrosion-resistant, non-conductive, and customizable properties. They provide a cost-effective and durable solution that contributes to enhancing safety on highways.

- Q: What are the load-bearing capabilities of FRP pultrusion profiles?

- The load-bearing capabilities of FRP pultrusion profiles are exceptional. Factors such as fiber type, arrangement, resin properties, and profile design determine their load-bearing capacity. Due to their high strength-to-weight ratio, FRP pultrusion profiles are widely used in various industries. The reinforcing fibers, made of materials like fiberglass or carbon fiber, provide the profiles with outstanding tensile and flexural strength. These fibers are embedded in a resin matrix, further enhancing the profiles' load-bearing capabilities. Manufacturers can customize the load-bearing capacity of FRP pultrusion profiles by adjusting fiber type, orientation, and resin properties. This flexibility allows for a wide range of design options, enabling engineers to optimize the profiles for different applications. Additionally, FRP pultrusion profiles have excellent corrosion resistance, making them suitable for harsh environments. Unlike steel or wood, they do not rust or rot, ensuring long-lasting durability and structural integrity. In conclusion, FRP pultrusion profiles have impressive load-bearing capabilities, making them a reliable choice for a variety of applications, including structural supports, bridges, platforms, and industrial equipment.

- Q: Are FRP pultrusion profiles electrically conductive?

- No, FRP pultrusion profiles are not electrically conductive.

- Q: Can FRP pultrusion profiles be used in automotive applications?

- Yes, FRP pultrusion profiles can be used in automotive applications. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. Additionally, FRP pultrusion profiles can withstand harsh environmental conditions, making them suitable for various automotive components, including body panels, structural supports, and interior parts.

- Q: Are FRP pultrusion profiles resistant to saltwater corrosion?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are highly resistant to saltwater corrosion. The corrosion resistance of FRP profiles is one of their key advantages over traditional materials such as steel or aluminum. The combination of the reinforcing fibers and the resin matrix used in FRP pultrusion profiles makes them inherently resistant to the corrosive effects of saltwater. FRP profiles are composed of a mixture of glass or carbon fibers embedded in a thermosetting resin. These materials do not react with saltwater, preventing the corrosion that occurs in metals when exposed to saltwater for an extended period. Additionally, the resin matrix used in FRP profiles provides a protective barrier that further prevents saltwater from reaching the reinforcing fibers. The corrosion resistance of FRP pultrusion profiles makes them ideal for applications in marine environments. They are commonly used in structures such as seawalls, dock fenders, offshore platforms, and marine vessels. The durability of FRP profiles in saltwater environments ensures long-term performance and reduces the need for frequent maintenance or replacement. However, it is important to note that while FRP pultrusion profiles are highly resistant to saltwater corrosion, they may still be affected by other factors such as UV radiation or chemical exposure. Therefore, it is essential to consider the specific environmental conditions and consult with manufacturers or experts to select the most suitable FRP profile for a particular application.

- Q: Are pultruded FRP sections strong? What are its main areas of application?

- More fields. Advantage is obvious, if the corrosion resistance, insulation resistance, quality is lighter than steel; strength and steel strength comparable;

- Q: Can FRP pultrusion profiles be used for structural applications?

- Certainly, FRP pultrusion profiles can be utilized for structural purposes. The process of pultrusion involves pulling fiber reinforcements through a resin bath and a heated die to cure the resin, resulting in robust, lightweight, and corrosion-resistant profiles with exceptional mechanical properties. The high strength-to-weight ratio of FRP pultrusion profiles makes them widely employed in different structural applications. These profiles can be engineered to possess specific load-bearing capacities, stiffness, and durability, making them suitable for a wide range of structural requirements. FRP pultrusion profiles find common use in various structural applications such as bridges, walkways, platforms, handrails, supports, beams, columns, and reinforcements in concrete structures. They are particularly advantageous in situations where traditional materials like steel or wood are unsuitable due to concerns regarding corrosion, electrical conductivity, or weight. The benefits of FRP pultrusion profiles are numerous. They are lightweight, making them easy to handle and transport. Furthermore, they exhibit resistance to corrosion, chemicals, and UV radiation, ensuring long-term durability even in harsh environments. Additionally, they possess excellent dimensional stability, remaining unaffected by warping, twisting, or shrinking over time. To summarize, FRP pultrusion profiles are highly suitable for structural applications owing to their strength, lightweight nature, corrosion resistance, and durability. They provide a cost-effective alternative to traditional materials while delivering superior performance in various structural projects.

- Q: Can FRP pultrusion profiles be used in the construction of chemical processing equipment?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of chemical processing equipment. FRP pultrusion profiles offer several advantages that make them suitable for such applications. Firstly, FRP pultrusion profiles are highly resistant to corrosion, making them ideal for use in chemical environments where exposure to corrosive substances is common. Unlike traditional materials such as steel, FRP pultrusion profiles do not rust or corrode, ensuring a longer service life and reducing maintenance costs. Secondly, FRP pultrusion profiles are lightweight yet strong, providing excellent structural integrity and load-bearing capacity. This is particularly important in chemical processing equipment, where the materials used must withstand high pressures and temperatures. The strength of FRP pultrusion profiles allows for the construction of robust and durable equipment. Additionally, FRP pultrusion profiles offer design flexibility, allowing for the customization of shapes and sizes to meet specific requirements. This enables the construction of complex chemical processing equipment with intricate designs that are not easily achievable with traditional materials. Furthermore, FRP pultrusion profiles have excellent electrical insulation properties, which can be advantageous in chemical processing equipment where electrical conductivity needs to be minimized to prevent unwanted reactions or hazards. Overall, FRP pultrusion profiles are a reliable and cost-effective choice for the construction of chemical processing equipment. Their corrosion resistance, strength, design flexibility, and electrical insulation properties make them suitable for a wide range of applications in the chemical industry.

- Q: Can FRP pultrusion profiles be used in the construction of oil storage tanks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of oil storage tanks. These profiles provide excellent corrosion resistance, high strength-to-weight ratio, and durability, making them suitable for storing various chemicals, including oil. Additionally, FRP pultrusion profiles are easily customizable, allowing for the construction of tanks of different sizes and shapes to meet specific requirements.

Send your message to us

FRP Pultrusion Profiles - Corrosion Resistant and Fire Resistant FRP Gratings with Modern Shape/Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords