High Quality Solid Wood Board Moulding Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 meters m³

- Supply Capability:

- 500000 per month m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Name:wood moulding

2.ISO/FSC certificate

3.Customized design

4.No warp in different temperature

5.Wood:alder, okume ,oak,sapele,cherry.

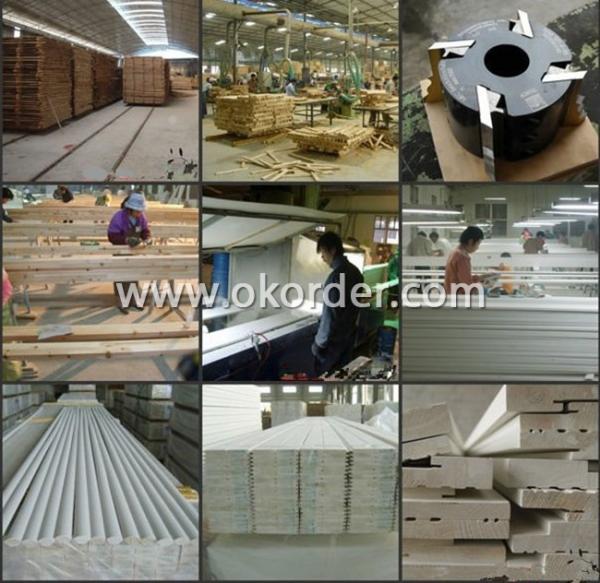

Manufacturing process of Solid Wood Moulding/Profile

1.Moulding preparation

The wood blanks are maufactured in mouling profiles.

2.Surface sand following moulding preparation, Machined(produced) with high speed planing equipment to yield a premium finish timber moulding ready for priming with a gesso coating.

3.Priming-stage:Mouldings are spray-coated with the 1st application of thin gesso coating.

4.Intermediate sanding stage:Surface sand following priming stage 1

5.Mouldings are spray-coated with the 2st(and final) application of water base primer.

6.Final product check with light sand and buff to the surface,that is readily painted with quality topcoats

Quality standards of Solid Moulding Profile

1.Moisture content must be accurately tested with an electronic moisture meter.

2.All dimensions should be within the dimensional tolerances as specified on the order

3.Coating application would be applied equally on all edges and has a strong adhesion to the wood substrate throug testing .No visible defects like

patching,open finger joints,bleed through,etc,after being coated/primed.

4. Mouldings would stay straight and not have excessive bow or spring.

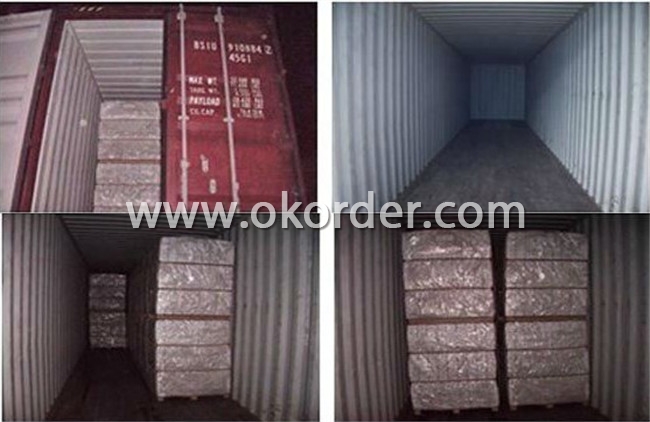

Packing&Loading

1.All mouldings to be packed in mini-bundles secured with tape, within the main pack structure.

2.Packs will be then strapped securely with poly strapping (to be confirmed by customer) to secure for shipment.

3.All bottom packs are secured to a plywood pallet that allows containerisation and unloading.

Species for Solid Wood Moulding/Profile

Production Progress for Solid Wood Moulding/Profile

Loading for Solid Wood Moulding/Profile

- Q: when you choose the big core board, be sure to saw a corner, check the quality inside.

- Good big core board, which between the small wood, have a jagged-shaped tenon interface.

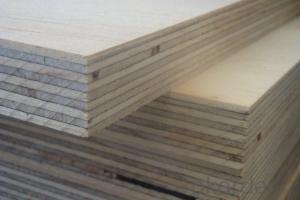

- Q: ulti-layer solid wood board shortcomings

- it may cause the separation and deformation of the plate, resulting in reduced service life.

- Q: Glulam, is not easily deformed

- .As the process is different, this board's environmental performance is superior, is a large core board to allow formaldehyde content of 1 / 8, the price of each 200 yuan or so, slightly more expensive than the high-end big core board.

- Q: hat is the environmental protection of solid wood and multilayer?

- At present, the market a lot of wood-based panels can be boldly claiming to "solid wood ... ... board", such as: solid wood particle board = particleboard.

- Q: Anti-injury of solid wood board

- Repair, whether it is nail-mounted, specifications, or paint colors, should strive to restore the original

- Q: What are the characteristics of solid wood, what are their characteristics

- First, the classification of wood 1, according to the material classification can be divided into: solid wood, wood-based panels two categories

- Q: Distinguish between ecological board and solid wood board

- TV cabinet, shoe cabinet, showcase, wine cooler, cut off health, commercial partition, office furniture and so on

- Q: melamine double paste board, not afraid of fire and water

- This board is shiny on both sides, very hard, not afraid of water and fire, mainly used in furniture and cabinets

- Q: What are the advantages and disadvantages of multi-layer solid wood board?

- because it is multi-layer plywood, so it is more hard than the other plate, solid structure, the appearance is also nice

- Q: The characteristics of wood-based panels and solid wood panels are as follows

- fiberboard. Fibreboard is the use of wood processing in the scrap, after crushing, pulping, forming, drying, hot pressing made of a wood-based panels

Send your message to us

High Quality Solid Wood Board Moulding Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 meters m³

- Supply Capability:

- 500000 per month m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords