High-Quality Wall Angle Ceiling Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

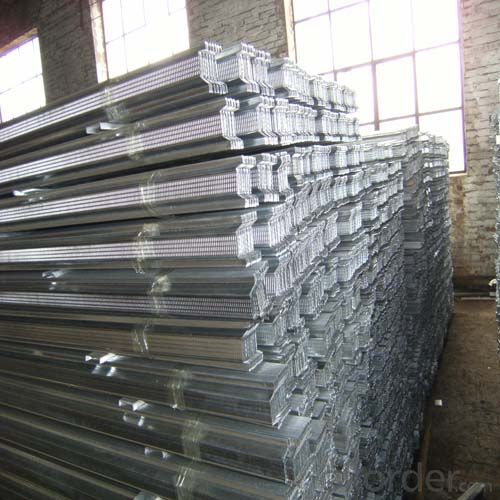

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel

Product Applications:

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

Main Product Features:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the

keels' vertical points and intensity.

(4) Various sizes of metal track and metal stud : we are able to manufacture German, Japan and Aus-American types etc..

We can meet your customized demands.

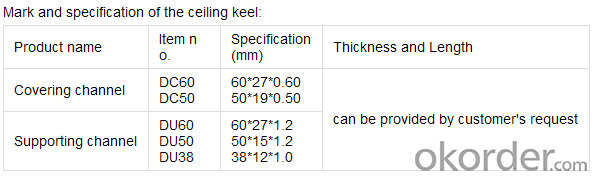

Product Specifications:

Images:

- Q: I am a novice . The How the keel is fixed on the ceiling of the hairy house. The Also gypsum board ceiling gypsum board is how to install on the keel I think: it will not fall? Is it to take nails or what glue up? What is the use of the boom (the ceiling will seem to use ..)

- Now the ceiling is generally light steel keel gypsum board ceiling. First of all, the hanging wire with the expansion of silk fixed on the ceiling hanging under a hanging piece is fixed on the main dragon. There is a buckle on the main dragon is stuck in the vice dragon. And then the gypsum board is used by the self-Gong Luo Luo on the vice dragon. Under normal circumstances as long as the operation in accordance with the norms do not have to fall off. Please rest assured that the landlord.

- Q: Light steel keel ceiling calculation method

- Per square meter ceiling need: The main keel 1 meter, deputy keel 2 meters, stays up the keel 2 meters, while the keel for the ceiling around the total length (with the room size, shape). If you want to calculate in detail, it is necessary to see how the layout of the keel on the drawings. for example: The main keel spacing of 1.2 meters, along the length of the layout of the room; vice keel spacing 0.6 m; stays keel spacing 0.6 m; room length 6 m, width 4.5 m. The main keel is: 4.5 ÷ 1.2-1 = 2.75 (root), rounding requires three main keels, keel spacing adjusted to 4.5 ÷ (3 +1) = 1.125 meters. The main keel needs: 6 × 3 = 18 meters. Vice keel is: 6 ÷ 0.6-1 = 9 (root), keel spacing just to meet the design requirements of 0.6 meters. Vice keel need: 4.5 × 9 = 40.5 meters. Hold the keel is: 4.5 ÷ 0.6-1 = 6.5 (root), rounding requires 7 stays keel, keel spacing adjusted to 4.5 ÷ (7 +1) = 0.56 m. Hold the keel need to: 6 × 7 = 42 meters. Side keel need: (6 + 4.5) × 2 = 21 meters. In the material plan, each should also be added to the loss of 1 to 3% OK!

- Q: Light steel keel and wood keel the difference

- Light steel keel advantage is not easy to deformation, the disadvantage is to do modeling difficult; The advantages of wood keel is easy to do all kinds of modeling, the shortcomings are easy to crack. Top construction method, classification, comparison: Wood keel ceiling: Wood keel is easier to do local shape, keel brush fire paint twice, keel with nails or nail fixed, each with two nails fixed, made 300 * 300 or 400 * 400 frame, Adjust the low, straight, after the acceptance of gypsum board, the use of self-tapping fixed, self-tapping density: 20cm, the edge part of the density should be some. Wood keel and light keel combination: Do not recommend this practice, the individual feel better than the complete wooden keel or completely light keel production of strong. And the construction time is relatively troublesome. Completely use light keel: Light steel keel is not easy to do local shape, the use of expansion screws, d nails, etc., to install more solid. Light Gang keel with fire, not easy to deformation, strong and so on, is currently widely used method. Whether it is a large area of ??the ceiling or local ceiling can use this method of construction. Ceiling Note: Top, the keel of the wall should be fixed with a wooden wedge, nail, or with an expansion bolt. Do not use spikes (easy to fall). When the gypsum board is installed, the gypsum board seams are staggered from the keel frame. Fixed gypsum board: the use of self-tapping fixed, do not agree with the use of spikes (nail many, small, easy to brush anti-rust paint).

- Q: Light steel keel ceiling one square meter how much money

- Now on the market of light steel keel ceiling is generally 30-40 / square meter, of course, different quality keel ceiling price is not the same, and now we come to understand the light steel keel ceiling installation method!

- Q: 140 square meters light steel keel double gypsum board ceiling fee, material costs about how much money

- The general cost of about 4,000 materials, first-line brand of materials costs around 7000, labor costs about 3000-4500 between ...

- Q: Light steel keel ceiling and wall construction technology

- Material purchase requirements 1. Light steel skeleton sub-U-shaped skeleton and T-skeleton two, according to the load and not on the master. 2. Light steel skeleton main pieces for large, medium and small keel; accessories hanging pendant, connectors, hanging plug. 3. Spare parts: a boom. Flower blue screws. Nail. Self-tapping screws. 4. According to the design can choose a variety of cover panels. Aluminum pressure or plastic pressure every bar, the material varieties. Specifications. Quality should meet the design requirements. 5. Binder: should be selected according to the performance of the main material, before use for bonding test.

- Q: I help people pull the line, to climb the ceiling, but the ceiling of the light steel looks thin, you can climb up? Afraid! I am now 120 pounds.

- The ceiling of the keel is divided into three kinds of specifications, two kind of not a man, a master, the man you stepped on the keel walking certainly no problem, not on the following 150 pounds can go, but the premise of his Keel must meet the national norms, wall thickness of 1.2mm or more.

- Q: Ceiling twenty square meters need light steel keel how many roots

- If the height of the room does not exceed 4 meters, usually: the main keel 1.2 meters, vice keel 4 meters (300MM open file), 1 meter pole, gypsum board 1.05 square (5% loss). Accessories too much here to do not introduce. The above calculation method is limited to flat top, if the shape plus 20% -30%

- Q: Light steel keel good or fir Fang Fang dragon skeleton good

- Light steel keel is good, will not be damp, will not be deformed, but not easy to do modeling, so there are a lot of home improvement with wood keel, because it is easy to do a variety of shapes, but to brush on the moisture and fire paint. 1, according to the order of operation. 2, wood keel no knots, wood keel then long to link firmly, boom and wood keel, floor link firmly. 3, keel should be painted fire anticorrosive coating. 4, suspended keel to consider the future sagging, so after installation, the center should be short side of the arch from 1/200. 5, where a lampshade, curtain box and other positions should increase the keel, ceiling fan shall not be in the dragon on the skeleton. 6, cover the panel should be flat, no Qiaojiao, from the skin, degumming and other phenomena, if the parquet, the design should be the design requirements. Slats, steel mesh plaster top 1, wood keel grid with the wooden ceiling. 2, lath joints must be staggered, the board should not be too light, slats and steel mesh are nailed. 3, lime paste must be fully mature, do not allow lime fixed particles, so as not to plaster from the bubble after the bubble. 4, slag dry, easy to water swelling, after the plaster dry and easy to crack, so the end of the ash should be sprayed with water after wetting, and then wipe the leveling layer to combine with each other. Light steel keel ceiling 1, the selection of light steel keel should meet the design requirements to ensure quality. 2, all in the ceiling of spare parts, keel should be galvanized pieces. 3, keel, boom, connectors should be the right position, the material formation, straight, connected firmly, no loosening.

- Q: Gypsum board ceiling side keel with a good side of the wood or supporting the light keel edge keel good?

- Work with wood keel is good, the quality is still supporting the light steel keel is good, at least not easy to deformation, not raw insects (fixed time when a few points)

Send your message to us

High-Quality Wall Angle Ceiling Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords