High Quality Pre-painted Aluminum Composite Sheets Los Angeles - Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

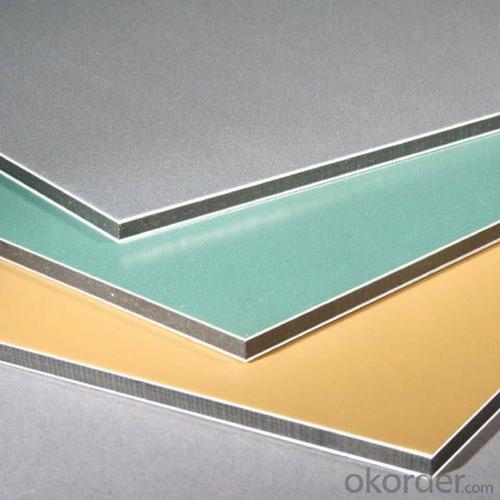

Structure of Prepainted Aluminium Sheet Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

It is widely used in architecture (corrugated sheet and light steel structure of houses; transporting industry (automobile roof, vehicle & ship separator, container); household light products (shell of refrigerator, cooler, washing machine, air conditioner, etc), as well as metal sheet processing products and furniture.

Main Features of Prepainted Aluminium Sheet:

High intensity

Low welding costs.

Outstanding color compatibility after anodizing

Easy to operate. All-position welding.

Excellent corrosion resistance

Images of Prepainted Aluminium sheet:

Prepainted Aluminium Sheet Specification:

Specification of prepainted aluminum coil sheet | |||

Substrates: | Aluminium (AA1100, 3003, 3004, 3105, 5006, 5052, 8011, etc), etc. | ||

Thickness: | 0.08-4.0mm | ||

Width: | << span="">1800mm | ||

Coils core diameter: | 150mm ,405mm, 505mm, 508mm, 510mm | ||

Coating thickness: | PVDF >=25micron POLYESTER>=18micron | ||

Color standard: | E < 2 or it is not obvious by eyeballing | ||

Pencil hardness: | > 2HB | ||

Coating adhesive: | not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) | ||

Bend stength: | >100 times | ||

Boiling point: | no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) | ||

Corrosive: | surface deep in the 5% muriatic acid and 5% NaCL, interior deep in the 2% muriatic acid and 2% NaCL, after 48 hours, no change | ||

FAQ of Prepainted Aluminium Sheet:

What's your package style?

Standard export packing as follow:

Plastic film wrapped inside and carton packing. Wooden pallet with steel strip tied.

Buyers can slao choose to pay for wooden case packing, which enables safer and more room saving in loading.

Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can 101 aluminum sheets be used in the production of decorative panels?

- Yes, 101 aluminum sheets can be used in the production of decorative panels. 101 aluminum is a commercially pure aluminum alloy known for its excellent formability and corrosion resistance. These characteristics make it suitable for various applications, including decorative panels. The aluminum sheets can be easily shaped, cut, and fabricated to create intricate designs and patterns for decorative purposes. Additionally, the corrosion resistance of 101 aluminum ensures that the panels will maintain their appearance over time, even in outdoor or high-moisture environments.

- Q: Are the aluminum sheets suitable for manufacturing electronic enclosures?

- Yes, aluminum sheets are suitable for manufacturing electronic enclosures. Aluminum is lightweight yet sturdy, providing excellent protection for electronic components. It is also corrosion-resistant, making it suitable for various environments. Additionally, aluminum is a good conductor of heat, allowing for effective thermal management in electronic enclosures.

- Q: A construction worker uses a steel tape to measure the length of an aluminum support column. If the measured length is 17.7 m when the temperature is 21.2°C, what is the measured length when the temperature rises to 35.4°C? (Note: Do not neglect the expansion of the steel tape. Give your answer to three decimal places.)I am really confused... Could someone solve it for me with a step-by-step explanation? Thank you so much.

- Assume linear thermal expansion with constant expansion coefficient. The change of length is given by: ΔL = L?·α·ΔT (L? initial length, α linear thermal expansion coefficient) The overall length of an object as function of temperature is: L= L? + ΔL = (1 + α·ΔT) · L? Consider the measurement at 21.2°C as reference: The aluminum column changes its length to L= (1 + α_aluminum · ΔT) · L? = (1 + 23×10-6 ^C°-1 · (35.4°C - 21.2°C) ) · 17.7m = 17.705m That would be the length measured with a steel tape at reference temperature of 21.2°C. Unfortunately the steel tape expands too. Because the scale increases with the expansion it measures too short. On the expanded tape you read the length L? while the actual length is L. Hence the measured length is: L? = L / (1 + α_steel · ΔT) = 17.705m / (1 + 11×10-6 ^C°-1 · (35.4°C - 21.2°C) ) = 17.003m

- Q: Aluminum plate thickness 1 cm, iron plate thickness 0.15 cm, area 1 square meters, thank you

- It's too difficult. Just think about it

- Q: I am looking for info on grades of aluminum like 3003, 5053, 6160 what's the differance witch one are cheaper and weld easy please explain

- Types Of Aluminum

- Q: What is the typical price range for aluminum sheets?

- The typical price range for aluminum sheets can vary depending on factors such as size, thickness, and quality. However, generally speaking, aluminum sheets can range anywhere from $0.25 to $3 per square foot.

- Q: Can aluminum sheets be used for bus shelters?

- Indeed, bus shelters can utilize aluminum sheets. Aluminum, a lightweight and enduring substance, finds extensive use in construction ventures, encompassing bus shelters. Its exceptional resistance to corrosion renders it apt for outdoor scenarios, where it confronts inclement weather. Moreover, aluminum sheets are conveniently malleable and can be fashioned into manifold forms and dimensions, permitting tailor-made designs and effortless installation. Employing aluminum sheets for bus shelters also entails a cost-efficient resolution as it demands scant upkeep and boasts a prolonged existence.

- Q: Can aluminum sheet be used for electrical enclosures?

- Yes, aluminum sheet can be used for electrical enclosures. Aluminum is a popular choice for electrical enclosures due to its excellent conductivity, lightweight nature, and corrosion resistance. It provides effective shielding against electromagnetic interference and offers good heat dissipation properties. Additionally, aluminum is easily formable, allowing for the creation of complex shapes and designs. Overall, aluminum sheet is a suitable material for electrical enclosures and is commonly used in various industries including electronics, telecommunications, and power distribution.

- Q: I'm making a project for class and I bought a 10 Inch long 5mm thick aluminum/metal, How do you cut it WITHOUT large machinery? is there any power tools adapters or tools that can do this job without a problem?Here is what I have to do:*Cut the metal into ~1x1 and 2X2inch squares*Somehow shave a circle about 2mm deep without going trough the 5mm aluminum (Shaded gray)*Drill a hole right through the 5mm (right in the center)*Drill screw holes on each cornerI provided a really basic pic of what I'm trying to dohttp://img204.imageshack.us/img204/487/77845398.pngRED=backgroundGRAY=drilled 2mm deep WITHOUT GOING THROUGHRED HOLES=screw holes with threadsPlz help need to finish this by friday!PS: Screw holes, and other sizes don't matter right now I'm just trying to figure out what tools/tool adapters I need thanks!

- If you have access to a table saw, mount the blade in backwards and then cut the aluminum. But I would cut it down to the correct size last. The extra length gives you a handle to use for the other operations. Regular hand or power tools will work. Get VERY coarse blades. The fewer teeth per inch, the better. Aluminum really clogs up toothed blades/cutting tools. For the 2mm deep recess, a regular spade bit should work and will drill a hole in the center for you. But if this is for a metal shop course, you should have all of the proper tools to do the job correctly. The methods I gave is if you don't have access to the proper equipment.

- Q: What is the typical wear resistance of aluminum sheets?

- The typical wear resistance of aluminum sheets can vary depending on the specific alloy and temper of the sheet. Generally, aluminum sheets have a moderate wear resistance compared to other metals. However, they are not as wear-resistant as materials such as steel or titanium. Aluminum sheets can withstand light to moderate wear and abrasion, making them suitable for applications where they are not subjected to excessive friction or impact. To enhance the wear resistance of aluminum sheets, they can be treated with coatings or surface treatments such as anodizing or painting. Additionally, the thickness and hardness of the aluminum sheet can also affect its wear resistance, with thicker and harder sheets generally offering better resistance to wear.

Send your message to us

High Quality Pre-painted Aluminum Composite Sheets Los Angeles - Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords