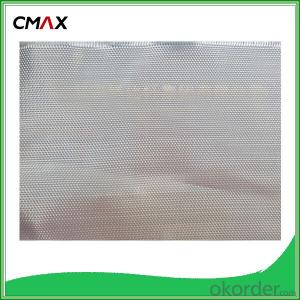

High Quality PP Woven Geotextile

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000m2 m²

- Supply Capability:

- 28 million M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Polypropylene Geotextiles:

Geotextile is usually used for filtration,isloation, reinforcement or preservation with good characteristics of high tensile strength, good penetrability,freezing durability,aging and corrosion resistance, etc.

Application of Polypropylene Geotextiles:

Geotextile has excellent permeability, acquired, durability, which can be widely used in railway, highway, movement hall, Dams, hydraulic structures, hence hole, coastal shoal, reclamation, environmental protection and other projects. The main products are Synthetic staple fibers needle punched non woven geotextiles and slit and spilt film yarn woven geotextiles.

Specification of Polypropylene Geotextiles:

Technical specification of short fiber needle punched non woven geotextile

No. | Item | Specification | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Weight Variation% | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width Variation % | -0.5 | |||||||||||

4 | KN/m≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD and TD |

5 | Elongation at Break % | 25~100 | |||||||||||

6 | CBR Mullen Burst Strength KN ≥

| 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Sieve Size O90 mm | 0.07~0.2 |

| ||||||||||

8 | Vertical Permeability Coefficient cm/s | K×(10ˉ1~10ˉ3) | K=1.0~9.9 | ||||||||||

9 | Tear Strength KN≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | MD and TD |

- Q: How do geotextiles improve the performance of geosynthetic clay liners?

- Geotextiles improve the performance of geosynthetic clay liners by acting as a cushioning layer, preventing the direct contact between the clay liner and the surrounding soil, which helps to reduce the risk of puncture or damage to the liner. Additionally, geotextiles enhance the drainage capabilities of the clay liner by allowing water to pass through while retaining the clay particles, which improves the liner's hydraulic conductivity and overall performance in terms of filtration and containment.

- Q: What are the specifications for geotextiles in roadways?

- Geotextiles used in roadways typically have specific specifications, including high tensile strength, puncture resistance, and durability to withstand heavy traffic loads. They are often made from synthetic materials like polypropylene or polyester, with a minimum weight per unit area to ensure sufficient strength and stability. Additionally, geotextiles for roadways should have proper drainage capabilities to prevent water buildup and promote better road performance.

- Q: How are geotextiles made?

- Geotextiles are made by weaving or knitting synthetic fibers together to form a fabric that is durable, permeable, and resistant to various environmental conditions. These fibers are typically made of materials such as polyester or polypropylene, which undergo a manufacturing process that includes extrusion, spinning, and heat treatment. The resulting fabric is then often coated or laminated to enhance its performance and functionality in various applications, such as soil stabilization, erosion control, and drainage systems.

- Q: Polypropylene geotextile and polyester geotextile with the naked eye how to distinguish

- Polypropylene compared to white, polypropylene fiber than polyester fiber density point, anti-aging anti-aging of polypropylene, polyester aging,

- Q: How do geotextiles affect soil permeability?

- Geotextiles can improve soil permeability by creating a pathway for water to flow through the soil, preventing clogging and enhancing drainage.

- Q: Geotextile and geogrid difference

- Different geotextile used to prevent seepage, geogrid used to reinforce the geotextile is mainly used to seepage, isolation, geogrid are generally used in reinforced reinforcement, the two are essential differences in the use of the process Sometimes used in the same project, such as high-speed, railway and other engineering production grid is made of polypropylene, polyvinyl chloride and other polymer polymer by thermoplastic or molded two-dimensional grid or a certain height of the three-dimensional Dimensional grid grid, when used as a civil engineering, known as geogrid. Engineering applications: roads, railways, abutments, approach roads, docks, dams, slag and other soft soil foundation reinforcement, retaining walls and road surface cracking engineering and other fields. Fiberglass mesh used in the external walls, wall paint, the main material to prevent the junction of different mortar and other plastering material cracking, hollowing. Local node reinforcement will also be used. Geotextile has excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. Common non-woven fabrics, water layer inside the use, polyethylene polypropylene waterproof also used.

- Q: Can geotextiles be used for reinforcement in retaining walls?

- Yes, geotextiles can be used for reinforcement in retaining walls. They are commonly used to provide stability and prevent soil erosion behind the retaining wall. The geotextiles act as a barrier, separating the soil layers and allowing water drainage while providing additional strength and stability to the structure.

- Q: What are the specifications for geotextiles in retaining wall construction?

- The specifications for geotextiles in retaining wall construction typically include requirements such as the tensile strength, elongation, permeability, and durability of the material. The geotextiles should have sufficient strength to resist the forces exerted by the retained soil, as well as the ability to allow water to drain through the fabric. Additionally, they should be resistant to degradation from UV exposure, chemicals, and biological agents to ensure long-term performance in retaining wall applications.

- Q: Can geotextiles be used in the construction of sports fields?

- Yes, geotextiles can be used in the construction of sports fields. Geotextiles are commonly used as a separation and drainage layer under the playing surface to prevent soil contamination, promote proper water drainage, and enhance the stability and longevity of the field. Additionally, geotextiles can help control erosion and provide reinforcement to the subgrade, ensuring a durable and high-quality sports field.

- Q: Where to sell waterproof geotextile

- Hello, waterproof geotextile is a composite geomembrane if necessary to the Department of Huazhi geotextile material manufacturers to answer the beginning of 135, 4791 last 9192, do not forget Oh

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2001 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% North America 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001; ISO14000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality PP Woven Geotextile

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000m2 m²

- Supply Capability:

- 28 million M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords