Geotextile Murah PP Woven Fabric, Woven Geotextiles, High Strength Geotextile

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Woven Fabric,Woven Geotextiles,High Strengh Geotextile

Desciriptions:

PP Woven Geotextile Professioal Waterproof Geotextiles. A woven geotextiles is an economical solution for any civil engineering applications. It separates, stabilizes, and reinforces soils and allos allows for filtration. Woven geotextiles are manufactured by extruding polypropylene film and then slitting the film into individual yarns which are then woven to form the geotextiles.

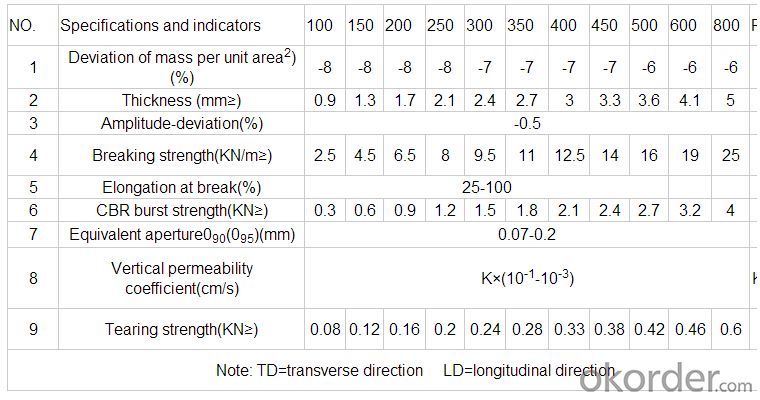

Specifications and Technical datas:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

Details of our products:

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

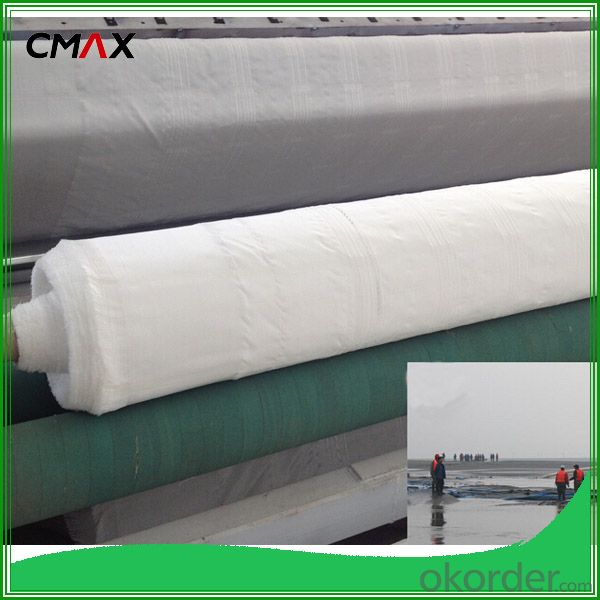

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Would like to know the product of the market

- According to geotextile specifications to offer. Ranging from $ 1-9.60.

- Q: Drainage board geotextile or gravel plus geotextile which water treatment effect is good

- Sure that the drainage board plus geotextile drainage effect is good, but the cost than the gravel Gao Hua Zhi geotechnical materials manufacturers to answer

- Q: How do geotextiles help with separation and stabilization in railroads?

- Geotextiles help with separation and stabilization in railroads by acting as a barrier between the subgrade and the ballast layer, preventing the mixing of materials and maintaining the integrity of the track structure. They also provide reinforcement by distributing loads more evenly, reducing settlement and promoting overall stability.

- Q: Can geotextiles be used in subsurface drainage applications?

- Yes, geotextiles can be used in subsurface drainage applications. Geotextiles are often used as a filter or separator in drainage systems to prevent soil erosion and clogging of drainage pipes. They allow water to pass through while retaining soil particles, thus enhancing the performance and longevity of subsurface drainage systems.

- Q: Are geotextiles commonly used in sports field applications?

- Yes, geotextiles are commonly used in sports field applications. They are often used as a base layer to provide stability, prevent soil erosion, and improve drainage in sports fields.

- Q: Is the polypropylene composite geotextile and the polyethylene composite geomembrane the same?

- Geotextiles and geomembranes are not the same, but they complement each other to meet the engineering requirements. First introduced under the geotextile: geotextile is the state for civil engineering in the construction of a new type of construction materials, by filament or short fiber through different equipment and process shop into a mesh, and then after acupuncture and other processes to different Fibers are intertwined with each other, tangent to the fabric to make the fabric normal, so that the fabric is soft, plump, thick, stiff, to meet the different thickness to meet the requirements, according to the length of silk is divided into filament non-woven geotextile or short wire Non-woven geotextile, filament tensile strength higher than the short wire. Fibrous soft with a certain tear resistance. The main role is: filter, filter, reinforcement role. Specifications from 100 grams per square meter to 800 grams per square meter. The main material for the polyester fiber, with excellent permeability, filtration, durability deformation adaptability, and has a good flat drainage capacity (see below) Geomembrane to plastic film as anti-seepage substrate, and non-woven composite Made of geotextile impermeable material can be divided into two cloth a film, a cloth a film, its impermeability depends mainly on the plastic film impermeability. The geomembrane is a waterproof barrier material with the polymer of the polymer chemical material as the basic raw material. The proportion of small, strong extension, high adaptability to adapt to deformation, corrosion resistance, low temperature, good frost resistance. (See below)

- Q: What are the key considerations for geotextile installation in areas prone to landslides?

- The key considerations for geotextile installation in areas prone to landslides include the selection of appropriate geotextile material, understanding the slope characteristics, conducting a thorough site investigation, ensuring proper anchoring and securing methods, and collaborating with experienced geotechnical engineers for design and installation guidance. Additionally, considering the long-term performance, maintenance requirements, and monitoring of the geotextile system is crucial to ensure its effectiveness in mitigating landslide risks.

- Q: How are geotextiles manufactured?

- Geotextiles are typically manufactured using a process called needle punching. This involves mechanically interlocking synthetic fibers together to create a strong and durable fabric. The fibers are first carded, meaning they are aligned and separated, before being fed through a machine that punches them with barbed needles. These barbs entangle and interlock the fibers, creating a stable fabric structure. Further processes such as heat setting, calendaring, and coating may be applied to enhance the geotextile's properties, such as increasing its resistance to UV degradation or improving its filtration capabilities.

- Q: How to determine the nominal breaking strength of filament spunbonded nonwoven geotextile

- You can use a dedicated geotextile strong test machine detected.

- Q: Are geotextiles suitable for use in geocell retaining walls?

- Yes, geotextiles are suitable for use in geocell retaining walls. Geotextiles are commonly used as a separation and filtration layer in geocell retaining walls to prevent soil erosion and provide stability. They help in reinforcing the structure and improving the overall performance and longevity of the retaining wall system.

Send your message to us

Geotextile Murah PP Woven Fabric, Woven Geotextiles, High Strength Geotextile

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords