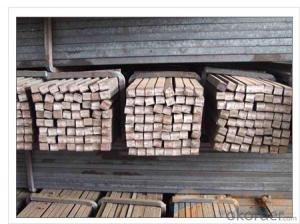

High Quality GB Standard Steel Square Bar 48mm-60mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

We offer Square Steel Bar with grade Q195 / Q235

Specifications of Square Steel Bar:

-Standard: GB,

-Grade: Q195/Q235 or equivalent.

Chemical Composition:

-Chemical Composition. Q195

Standard | Grade | Element (%) | ||||

GB | Q195 | C | Mn | S | P | Si |

0.06~0.12 | 0.25~0.50 | ≤0.050 | ≤0.045 | ≤0.30 | ||

-Chemical Composition. Q235

Standard | Grade | Element (%) | ||||

GB | Q235B | C | Mn | S | P | Si |

0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 | ||

Measures and Tolerances of Square Steel Bar:

(The section of Square Steel Bar)

-The length of a side and the theoretical weight of Square Steel.

Length of a side(a, mm) | Theoretical weight(kg/m) | Length of a side(a, mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 79 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-The allowed tolerance of Square Steel:

Length of a side(mm) | Allowed Tolerance | ||

Group1 | Group2 | Group3 | |

5.5~7 | ±0.20 | ±0.30 | ±0.40 |

7~20 | ±0.25 | ±0.35 | ±0.40 |

20~30 | ±0.30 | ±0.40 | ±0.50 |

30~50 | ±0.40 | ±0.50 | ±0.60 |

60~80 | ±0.60 | ±0.70 | ±0.80 |

80~110 | ±0.90 | ±1.0 | ±1.1 |

110~150 | ±1.2 | ±1.3 | ±1.1 |

150~190 | ―― | ―― | ±2.0 |

190~250 | ―― | ―― | ±2.5 |

Usage/Applications of Steel Square Bar:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery of Steel Square Bar:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

- Q: How do you use a steel square to measure board diagonals at different points?

- To use a steel square to measure board diagonals at different points, follow these steps: 1. Place the steel square on one corner of the board, making sure that one edge of the square aligns with one edge of the board. 2. Slide the square along the edge of the board until the other edge of the square aligns with the opposite edge of the board. 3. Take note of the measurement on the steel square where it intersects the opposite edge of the board. This measurement represents the diagonal length of the board at that specific point. 4. Repeat steps 1-3 for each corner of the board, ensuring that the steel square remains aligned with the edges. 5. Compare the measurements of the diagonals at different points to check for any variations. If the measurements are consistent, it indicates that the board is square. However, if there are discrepancies, it suggests that the board is not perfectly square. By using a steel square in this manner, you can accurately measure the diagonals of a board at multiple points to determine its squareness and identify any irregularities.

- Q: Can a steel square be used for checking the alignment of drill press tables?

- Indeed, the alignment of drill press tables can be verified using a steel square. This versatile tool serves the purpose of measuring and checking right angles. To guarantee proper alignment, simply position the steel square against both the drill press table and the drill bit. This ensures that the table is perpendicular to the drill bit, resulting in accurate and precise hole drilling. Moreover, the steel square can also assess the squareness of the table itself, preventing any tilting or misalignment. In conclusion, the steel square proves to be a practical tool for confirming the alignment of drill press tables.

- Q: Can a steel square be used for checking the plumbness of a support post?

- The plumbness of a support post is not typically checked using a steel square. A steel square, also known as a framing square, is primarily utilized in carpentry and woodworking to measure angles and create square cuts. It is composed of a long arm and a shorter arm that intersect at a right angle, forming an "L" shape. For checking the plumbness of a support post, a level is the more suitable tool. A level is specifically designed to ensure vertical alignment and determine if an object is perfectly plumb. It usually consists of a long, straight body containing a bubble vial filled with liquid and an air bubble. When the bubble is centered between the two lines in the vial, it indicates that the object is perfectly vertical or plumb. Using a steel square to assess the plumbness of a support post may not yield accurate results since it is not specifically designed for that purpose. It is always recommended to use the appropriate tools for the task at hand to ensure precise measurements and reliable outcomes.

- Q: Can a steel square be used for checking the alignment of beams?

- Yes, a steel square can be used for checking the alignment of beams. The steel square has a 90-degree angle and can be placed along the edges of the beams to ensure they are perfectly perpendicular or parallel.

- Q: What are the different ways to hold a steel square when making angle measurements?

- There are three main ways to hold a steel square when making angle measurements: 1) Holding it against the edge of the workpiece and using the inside corner as a reference point, 2) Placing it on top of the workpiece and aligning the blade with the desired angle, and 3) Holding it against the workpiece and using the outside corner as a reference point.

- Q: Can a steel square be used for marking out dovetail joints?

- Yes, a steel square can be used for marking out dovetail joints. A steel square is a versatile tool that can be used for measuring and marking angles accurately, making it suitable for marking out the precise angles required for dovetail joints.

- Q: What are some common features of steel squares?

- Steel squares possess several common characteristics, including: 1. Material: Crafted from high-quality steel, these squares exhibit exceptional durability and strength. 2. Shape: Typically resembling a right-angled triangle, steel squares possess one elongated side and two shorter sides that form a perfect 90-degree angle. 3. Precision: Meticulously engineered, steel squares guarantee precise measurements and angles. Their edges and corners undergo meticulous machining to deliver consistent and accurate results. 4. Markings: Often adorned with markings along their edges, steel squares offer users the ability to measure and indicate specific lengths or angles. 5. Graduations: Some steel squares are embellished with engraved or printed scales, allowing for easier measurement of angles or distances. 6. Versatility: Steel squares serve a multitude of purposes, including measuring, marking, and verifying right angles, as well as determining and transferring angles. 7. Size and weight: Steel squares are available in various sizes, ranging from compact pocket-sized squares to larger ones designed for heavy-duty applications. The weight of a steel square varies depending on its size and thickness. 8. Corrosion resistance: To prolong their lifespan, steel squares are often treated or coated to enhance their resistance to rust and corrosion. 9. Stability: Engineered for stability and rigidity, steel squares provide a dependable reference point for precise measurements and layout work. 10. Multi-functionality: Certain steel squares may incorporate additional features, such as built-in spirit levels, scribing tools, or adjustable components, offering enhanced versatility and convenience for specific applications.

- Q: How do you use a steel square to determine the angle of a compound spindle sanding cut?

- To use a steel square to determine the angle of a compound spindle sanding cut, you would first position the steel square against the spindle at the desired angle. Then, you can measure the angle formed between the square and the spindle using the markings on the square. This measurement will help you determine the exact angle for your compound spindle sanding cut.

- Q: What are some common uses of a steel square in metalworking sculpture?

- The steel square, also referred to as a framing square or a carpenter's square, serves multiple purposes in metalworking sculpture. It is a versatile tool commonly utilized for various tasks. Some of the common applications encompass: 1. Layout and marking: When working with metal sheets or other materials, the steel square plays a vital role in marking and laying out precise measurements. It facilitates the creation of straight lines, right angles, and accurate measurements. This ensures that the sculpture maintains proper alignment and symmetry. 2. Squareness verification: Metalworking sculptures often necessitate precise angles and right-angled corners. The steel square permits sculptors to verify squareness, guaranteeing perfect alignment of all corners and edges. This prevents distortions or irregularities in the final piece. 3. Measurement and dimension transfer: Metalworking sculptures require precise measurements for cutting, shaping, and joining various components. The steel square enables sculptors to measure and transfer dimensions accurately, ensuring the correct sizing and fit of different parts of the sculpture. 4. Miter cut creation: Miter cuts, which involve angled cuts made on the ends of metal pieces to create clean and tight joints, are a common technique in metalworking sculpture. The steel square aids in marking and cutting precise angles, facilitating seamless connections between different metal elements. 5. Flatness verification: The steel square can be employed to check the flatness of metal surfaces, ensuring they are level and even. This is particularly crucial when working with large metal sheets or when joining different components, as any unevenness can impact the overall stability and appearance of the sculpture. 6. Parallel line creation: Achieving symmetry or guiding the placement of various elements often requires parallel lines in metalworking sculpture. The steel square allows sculptors to effortlessly create parallel lines, ensuring uniformity and balance in the design. In conclusion, the steel square is an indispensable tool in metalworking sculpture. It aids artists and craftsmen in achieving precision, accuracy, and consistency in their work.

- Q: Can a steel square be used for checking the squareness of a deck frame?

- Indeed, the squareness of a deck frame can be assessed using a steel square. A steel square, which is also known as a framing square or carpenter's square, is a versatile tool commonly employed in the fields of carpentry and construction. It is comprised of two arms that intersect at a right angle, one of which is longer than the other. To evaluate the squareness of a deck frame utilizing a steel square, adhere to the subsequent steps: 1. Position the longer arm of the steel square against the edge of the deck frame, ensuring it is flush. 2. Extend the shorter arm of the steel square along the adjacent edge of the frame. 3. Observe for any gaps or incongruities between the frame and the steel square. If the frame is perfectly square, the steel square should align flawlessly with the edges of the frame. 4. In the event of gaps or misalignments, rectify the frame by gently tapping or pushing it until it achieves squareness. 5. Repeat this procedure for all corners of the deck frame to guarantee overall squareness. Employing a steel square is an efficient and dependable approach to ascertain the squareness of a deck frame. It furnishes a visual reference to ensure the frame maintains squareness, which is imperative for proper installation and structural soundness.

Send your message to us

High Quality GB Standard Steel Square Bar 48mm-60mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords