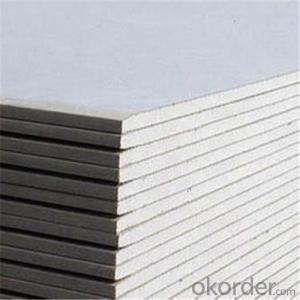

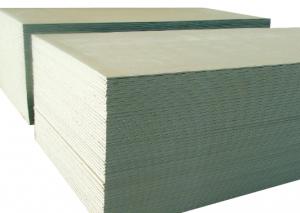

High Quality Fire-Resistant Gypsum Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1) Sepcial healthy breath function

2) Cost effective and more reliable, easy to install

3) moisture-resistance Fireproof

durable moistureproof gypsum board

1)Raw materials

gypsum powder,gypsum retaining paper,fiber(wood fiber,paper fiber,fiber glass),corn, starch,vesicant,lightweight aggregate,citric acid,water,adhesive,etc.

2)Product Description(size and thickness)

Normal size: 2440x1220mm, 2400x1200mm 3600*1200,3000*1200,1830*1220.

Normal thickness scope:7.0,7.5,8.0,8.5mm,9mm,9.5mm10mm,12mm,15mm.

Length scope: 1800-3660mm, Width scope: 900-1220mm,

Thickness scope: 6.00-15.90mm .

About other specification, we could process for you according to your special demand.

3)Qyality standard(thickness):

parametedr | Length | width | thickness | diagonal | unit area mass | landscape breaking load | potait breaking load |

|

|

|

|

tolerance | -4 to 4 | -4 to 0 | ±0.5 | less than 5mm | 7.0±0.3Kg | more than 140N | more than 400N |

|

|

|

|

4)Packing:

Two pieces glued together, packed by hand with labels on.

5)Loading

SIZE(mm) | KGS/PC | PCS/20GP | SQM/20GP |

1200*2400*7 | 17 | 1180 | 3398 |

1200*2400*7.5 | 18 | 1150 | 3312 |

1200*2400*8 | 18.2 | 1080 | 3110 |

1200*2400*9 | 22.1 | 970 | 2793 |

1200*2400*9.5 | 22.8 | 940 | 2707 |

1200*2400*10 | 23.5 | 900 | 2592 |

1200*2400*12 | 29.5 | 720 | 2073 |

1200*2400*12.5 | 30 | 710 | 2044 |

1220*2440*7 | 17.55 | 1160 | 3453 |

1220*2440*7.5 | 18.14 | 1130 | 3363 |

1220*2440*8 | 18.58 | 1060 | 3155 |

1220*2440*9 | 22.83 | 950 | 2827 |

1220*2440*9.5 | 23.55 | 920 | 2738 |

1220*2440*10 | 23.83 | 900 | 2679 |

1220*2440*12 | 30.5 | 700 | 2083 |

1220*2440*12.5 | 31 | 690 | 2053 |

- Q: I'm buying a cheap floating shelf for 20 so I can hang it on my bedroom wall (plasterboard). I'm buying it for a new stereo I'm getting , but I don't know how to hang the shelf up. I read somewhere that if you're putting a floating shelf on plasterboard you need to use toggle bolts. Can I just drill the holes in the wall , put wall plugs in , and then screw the shelf in to them. The stereo is a Samsung mini system with two seperate speakers. How can I put it up without a chance of it falling down ?

- A shelf is a simple lever. If you have, say, a shelf 10 wide with a 2 vertical bracket, that's got a mechanical advantage of 5 - if you put a 10lb stereo on the edge of the shelf, there's 50lb of force trying to pull the top bolts out. So it depends on the shape of the shelf, the weight of the stereo, how far it is from the wall etc. Most likely it will be OK until you accidentally grab the shelf one day, in which case if you just used wall plugs they will tear out and everything will fall to the floor. If you can, try and get at least one screw into a stud and use toggles for the others.

- Q: Black mirror attached to the wall above the wall is 2.8 meters long 0.37 wide, can live it, hang the glue with the marble, the mirror with a gypsum board to do the following and the mirror almost thick bottom, but also to catch, ? Similar to the L line gypsum board on the mirror

- The base of the lens is preferably sandwich, or the base of the nine-board. This is the standard base material. In the paper gypsum board on the lens, the actual is also posted, but theoretically is not possible. Keep the room dry. The bottom with a care can be better.

- Q: Gypsum board partition with what norms

- 1, the wall of the gypsum board should be from the side of the wall to start the end, the order of installation. After the installation side, the wall of a variety of pipelines, sockets, switches and other concealed works to install. To be concealed works acceptance is completed, and then install the other side of the gypsum board. 2, gypsum board should be vertical laying, long side joints should be installed in the vertical keel. Gypsum board with the keel overlap width should not be less than 20mm. 3, gypsum board along the edge (cut off) application of the top plate lift, about 10mm from the ground, not directly placed on the floor. 4, gypsum board along the floor with the top should be tight, leaving no gap. The top of the partition wall should be left 10mm gap, embedded sealant. Fireproof wall and top sliding wall top construction practices, see "Light steel keel gypsum board partition" GJT 002 in the relevant nodes. 5, gypsum board must be wrong to install (including vertical joints, transverse joints, keel on both sides of the board, both sides of the double-sided board and keel side of the other side of the double board). 6, light steel keel application special anti-rust self-tapping screw fixed and electric screwdriver once into and tighten. Along the gypsum board around the screw spacing to 200mm is appropriate, the plate screw spacing to 300mm is appropriate; screw from the edge of the edge should be 10 ~ 15mm, from the cutting edge should be 15 ~ 20mm.

- Q: Construction method of wood keel gypsum board

- Simple description The production process is: first with wooden keel frame structure, ceiling wood keel should be coated with fire retardant paint, hanging on the main keel. Ladder-type ceiling with blockboard and wood composition. Wood keel do a good job after the paper gypsum board, paper gypsum board and keel connection must use self-tapping screws, screw head must enter the board 2mm or so, is strictly prohibited using gun nail, because the paper gypsum board strength is low, Small surface, easy to cause paper and gypsum board layer, and the paint construction caused great trouble. Gypsum board splicing should be left about 5mm gap, to prevent the damp expansion caused by the top of the arch. Paste gypsum board base treatment when applied anti-rust paint the screw point, otherwise the rust will penetrate the surface. And then the patchwork with elastic putty approved flattened with a white bandage, then full approval, the general approved scraping two to three times, dry after grinding smooth, and finally coated with paint. For the installation of the ceiling of the ceiling due to the low strength of the plaster board, so gypsum board and keel should be added between a layer of plywood, so that the installation and maintenance of the lamp when you can prevent damage to the plaster board, Of the installation of fastness.

- Q: The mirror is about 75cm wide and 50cm high. Can it be hung on a plasterboard wall? What type of screws or nails do I need?

- Yup, just like the answer before mine say's you need the proper wall-anchors for it and you will all set.

- Q: how do i get tiles off a plasterboard wall?

- Is it wire mesh paster? If so you take two methods: one, beat it to death with a sledge hammer two- use a skill saw with combination blade (masonry-wood-metal) and cut into sections. Less dust and mess this way! Probably a bathroom wall?

- Q: What is the proportion of gypsum board?

- Gypsum board generally used surface density measurement, for example: 9.5mm thickness gypsum board, the national standard requires its surface density to be less than 9.5Kg / m2, but most of the better quality gypsum board density control in (6.5-7.2) Kg / M2. If compared with the density of water, the proportion of ordinary gypsum board is less than water. But the refractory board due to gypsum core inside the addition of glass fiber, depending on the amount of added, the density may be greater than the density of water.

- Q: it is always a dry wall

- Sure there are different glues made that allow you to glue drywall straight to a brick or concrete block wall. The one problem with brick is that they are sometimes uneven and getting the drywall to contact the brick wall evenly in all places is difficult and can lead to a wavy wall line. What I suggest is to glue furring strips, something like a 2x2 to the brick wall at 16 on center. Use a glue like Liquid Nails Heavy Duty. The best way is to use the quick set-up method. Simply run a bead of glue on the furring strip and place it on the wall where you intend to put it and push it firmly. Then pull it back off the wall and let the glue sit up for about 10 minutes. If you do this, after waiting 10 minutes, you can place it back on the wall and push it firmly in place, and you will not be able to pull it back off. I would also suggest, before gluing, to hold each strip on the wall where they will be going and check for a high spot that may be causing problems. You can always notch out the wood if you find a problem area. The other reason I would use the wood furring strips is that you can always use nails in the wall to hang things later on.

- Q: Im doing a loft conversion and have got to the boarding out stage, i need to buy a load of plasterboard but have found wallboard and baseboard are cheaper. should i go for the cheaper baseboard or pay the extra for plasterboard

- or you can get some drywall base boards go on the bottom of the wall where it meets the floor plaster board is for patching a broken ceiling u can use drywall to its all basically the same thing but drywall is the cheapest for sure

- Q: Gypsum board partition and brick wall connection, how to build to achieve no cracks

- Seam cracking is a wide range of reasons, there are foundations, stress, shrinkage, etc., if only consider the seam due to the expansion coefficient of the material and cause less deformation of the stress, the following materials can be used: 1, seams at the first treatment, with gypsum forward powder, and with a good tension of the joint tape, do not use mesh cloth; 2, the wall selection of plaster base putty, put three times, before the construction of water-based interface agent must be done; 3, the construction level of workers accounted for a large factor. As for the principle of gypsum material is a chemical process of change, think about whether the gypsum products are cracked to understand, because the gypsum in the crystal hard when the expansion is, so it will not crack, shrink will crack.

Send your message to us

High Quality Fire-Resistant Gypsum Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords