High Quality Gypsum Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

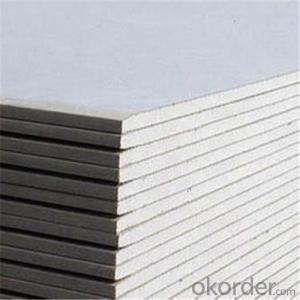

CMAX Gypsum Board Drywall Introduction.

Your drywall can be virtually any shape, anywhere. Choose from a wide range of heavy-duty system options that provide code-compliant performance in both fire rated and non-fire rated applications with labor-saving advantages.

1.Gypsum Board Drywall Specification.

| Convenient Construction | The plaster board can be constructed easily by nailing ,cuting and planing,and thus it becomes the first choice among home decoration materials. |

| Raw material | The gypsum board is characterized for lightness and high intensity,dryness operation, green environmental protect, convenient construction and good processing quality. |

| Size | 595x595 |

| 605x605 | |

| 1200x2400 | |

| 1220x2440 | |

| Thickness | 7,7.5,8,9,9.5,10,12,12.5,13,15,15.9 |

| Surface treatment | Paper/PVC laminated/foil back |

| Production capacity | 10,000m2/day |

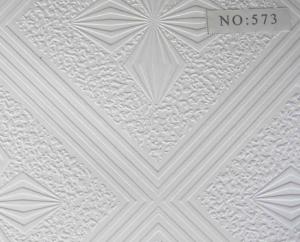

2.Gypsum Board of ceiling & wall partition system.

CMAX System is a modern, non load bearing and quickly assembled on site. The system consists of Gypsum Board screw fixed to lightweight galvanized metal sections and joint finished with drywall system is suitable for all internal applications for commercial and residential.

CMAX drywall system provides smooth, seamless and crack-free wall surface. Thanks to the distinctive property of PRANCE gypsum Board, it allows easy further decoration by either painting or wallpaper work. Moreover, a renovation can be done easily without any disturbance of office building structure.

Durable and Standard Quality

Lightweight, Easy to Install and Economic

Specially Designed and Patented Materials of Gyproc

Applicable to Various Usages as Required

Office buildings requiring extra fine resistance, standard drywall system can provide a half-hour fire resistance. Other drywall Systems are also available to provide resistance up to 2 hours.

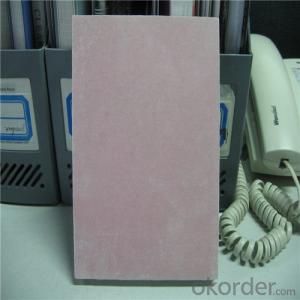

Other special properties such as heat insulation wall, high moisture resistant wall, acoustic wall, can also be provided by drywall system.

Loading

Transportation: By 20'Container or 40'container

sizes | Quantity |

2400*1200*8 | 1150(20FCL) |

2400*1200*9 | 970(20FCL) |

2400*1200*9.5* | 950(20FCL) |

2400*1200*12 | 750(20FCL) |

2430*1210*8 | 1150(20FCL) |

2430*1210*8.5 | 1100(20FCL) |

3000*1200*12 | 1050(40 FCL) |

3000*1200*9.5 | 850(40FCL) |

Loading port: Qingdao port

Origin: Shandong china

6)Fuction,Advantage and Use

- Q: Three building materials, plasterboard, brick, and wood, all the same thickness and area, are sandwiched to form a wall. Temperatures are 27 degrees Celsius at the inside plasterboard surface and 0 degrees celsius at the outside wood surface. Find the temperature where the plasterboard meets the brick and where the brick meets the wood.k for plasterboard = .40k for brick = .70k for wood = .2

- 1/0.4+1/0.7+1/.2 = 7.5+1/.7 or about 8.93 the plasterboard drops 27*2.5/8.93 C : about 7.7C so temperature at plasterboard/brick is around 19.3 C the wood drops twice as much about 15.2C so brick-wood interface is around 15.2C. Appropriate numerical precision when the conductivities are given to 2 significant figures means your answers should be about 19C and 15C. The brick is awful! Have a look at the link below; even thermal grease isn't much worse than this brick but the values do seem to be pretty typical.

- Q: I have some plasterers doing some work in my kithchen at the moment, and i've just had the kitchen damp proffed with injection and a roll of bitchumen membrane up to approx a metre high all round the kitchen. The plasterers have told me that the dry wall won't stick to the bitchumen membrane, so have suggested putting up a stud frame all round the kitched so that they can screw the plasterboards to the new stud frame!! Is this really necessary?? Does plasterboarding with dry wall adhesive really not stick to sheet roll's of bitchumen?? Also, they have also told me that you can't drywall with foil back boards as the adhesive won't stick to the foil....is this also true???Many thanks

- plasterboard or sheetrock is not glued to any backing. It must be nailed or screwed onto a frame. never heard of the adhesive way.

- Q: please help!

- u need to have the right brackets and self tapping plaster bord screws to find good fixing place by tapping wall till u find a good fixing place

- Q: Replace rippled plasterboard tape?My house's interior walls are all plasterboard - not plaster on brick. As is usual with modern houses (built 1995) the vertical joints at the corners of the walls are joined by plasterboard tape. Unfortunately due to differential expansion/contraction the tape has become rippled. As I am about to paint a bedroom, should I replace the rippled tape with new plasterboard tape and apply some kind of polyfilla, smooth and sand it, OR expect continued minor movement and fill the corners with some kind of decorators caulk instead of plasterboard tape?I should add I think the movement is because the walls are made of different materials - one is an end wall - plasterboard on brickwork, the other a sloping ceiling, presumably plasterboard nailed to batons?? So, different degrees of exapnsion / contraction according to the temperature rather than settlement.

- The first answer is good. But you should know about fiber glass wallboard tape. It is a lot stronger than the paper but you need to completely embed it in compound. Otherwise it will show when sanded.

- Q: what is the going rate for hanging plasterboard?square ft>?

- $30 to 45 per hour

- Q: Construction method of wood keel gypsum board

- First with wooden keel frame structure, ceiling wood keel should be coated with fire retardant paint, hanging on the main keel. Ladder-type ceiling with blockboard and wood composition. Wood keel do a good job after the paper gypsum board, paper gypsum board and keel connection must use self-tapping screws, screw head must enter the board 2mm or so, is strictly prohibited using gun nail, because the paper gypsum board strength is low, Small surface, easy to cause paper and gypsum board layer, and the paint construction caused great trouble. Gypsum board splicing should be left about 5mm gap, to prevent the damp expansion caused by the top of the arch. Paste gypsum board base treatment when applied anti-rust paint the screw point, otherwise the rust will penetrate the surface. And then the patchwork with elastic putty approved flattened with a white bandage, then full approval, the general approved scraping two to three times, dry after grinding smooth, and finally coated with paint. For the installation of the ceiling of the ceiling due to the low strength of the plaster board, so gypsum board and keel should be added between a layer of plywood, so that the installation and maintenance of the downlight can prevent paper gypsum board damage, Of the installation of fastness.

- Q: How can I best cover up or disguise where the old strip lights were? Will new artex be the same colour as the existing? Should I consider repainting the ceiling?

- For a professional looking job you should repaint the ceiling. Use a lightweight premixed spackling compound...apply it over the damaged plasterboard with a putty knife and smooth to make a flush surface, after it is completely dry, sand any rough or uneven areas if necessary, paint with primer, then paint.

- Q: Gypsum board wall is 19MM thick it?

- Have. Double 9.5mm gypsum board

- Q: Under what circumstances to use double gypsum board ceiling

- In general, only high-star hotel and high-end hardcover residential will use double ceiling (keel need to use at least the national standard light steel keel), the advantage is high flatness, easy to crack.

- Q: Gypsum board sowing the specific practices and seam width

- First with woodworking board, do not play full, only need to stay in the place to play full, the other place is drilling wells grid, and then cut into pieces of gypsum board, nailed to the woodworking board, leaving the place to stay That is, to do out of the rough is: a large market gypsum board, leaving the place is the carpentry board, leaving the width of the seam is generally about two centimeters

Send your message to us

High Quality Gypsum Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords