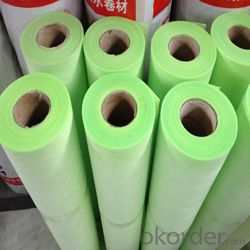

High polymer pp pe pp waterproof membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Polymer polyethylene polypropylene composite

waterproof membrane

PP+PE+PP composite waterproof membrane is made by multipleply different materials,

especially its aging and weathering resistance layer enables the membrane possess

more longer effective age. It can bond with many kinds of adhesions, firm and secure.

In case of cement-base, cementations agent can be used, the cementationsagent

can easily enter into the non-woven felt layer, forms a well-combination with cement

after solidification, permanent durability.

1.Specifications:

2.Core Material: PE, EVA

3.Color: black, white, green, grey

4.Weight: 300g/m2-800g/m2

5.Length: 100M, 50M

6.Width: 1.15M, 1.20M, 1M

7.Thickness: 0.6mm-1.5mm

8.Technics: Heat synthesis

9.Payment: T/T

10.Port: Qingdao

11.Origin: CHINA

12.Packaging & Delivery: Packed in roll, will deliver after 7-14 days after receive the prepayment

Characteristic:

1. Non-toxic, no pollution, environmental protecting product.

2. Can be used for many different surfaces, especially for cement basement.

3. Tough, impermeable, multi-layered sheet;

4. High tension strength, good cold flexibility.

Application:

Products used in roofing, basement, restroom, water conservation, warehouse to

protect structure from water infiltration.

Construction:

1.The application is simple and no-pollution. It is mainly used in the middle of building

for waterproofing. On this layers of protection and decoration are needed;

2. When application, pour the adhesive materials homogeneously on the smooth roof

deck, then roll the membrane to make is fully adhered to the deck.

3. The adhesive materials are usually made form cement or other building glue

- Q: Does a waterproofing membrane require any special tools or equipment for installation?

- Yes, a waterproofing membrane typically requires specific tools and equipment for installation. These may include a trowel or roller for applying the membrane, a utility knife for cutting the material to size, a brush or sprayer for applying adhesive or primer, and a heat gun for activating self-adhesive membranes. Additionally, some installations may require specialized equipment such as a hot air welder for joining seams or a pressure washer for surface preparation.

- Q: Can a waterproofing membrane be used on roofs with skylights?

- Yes, a waterproofing membrane can certainly be used on roofs with skylights. In fact, it is highly recommended to use a waterproofing membrane around skylights to prevent any water infiltration or leakage. Skylights are potential weak points in a roof system, as they create openings that can allow water to seep through if not properly sealed. By applying a waterproofing membrane around the skylights, it helps to create a watertight barrier that protects the roof from any potential leaks. Additionally, a waterproofing membrane can also provide added protection against other elements such as UV rays and temperature fluctuations, prolonging the lifespan of both the skylights and the roof itself.

- Q: What is a waterproofing membrane?

- To prevent the passage of water or moisture, one can apply a thin layer or sheet of material known as a waterproofing membrane onto a surface. This technique is widely utilized in construction, especially in areas where water infiltration is a concern, like roofs, basements, and bathrooms. By acting as a barrier, the membrane effectively stops water from seeping through and causing harm to the underlying structure. Enhancing its effectiveness, multiple layers of the membrane are typically applied, which can be composed of various materials such as rubber, bitumen, or synthetic polymers. In order to endure environmental factors like UV radiation and temperature fluctuations, these waterproofing membranes are meticulously designed to be flexible, durable, and resistant. By keeping buildings dry and safeguarding them from water-related problems such as leaks, mold, and deterioration, they play a crucial role in ensuring the longevity and integrity of structures.

- Q: Can a waterproofing membrane be used for underground bunkers?

- Yes, a waterproofing membrane can be used for underground bunkers. Waterproofing membranes are designed to create a barrier against moisture, preventing water penetration into structures. This makes them an effective solution for underground bunkers, which are susceptible to water infiltration due to their underground location. By applying a waterproofing membrane to the walls and floor of the bunker, it can help to prevent water seepage and keep the interior dry. This is crucial for the protection of any stored items or occupants within the bunker. Additionally, waterproofing membranes can also provide added benefits such as insulation and protection against radon gas. It is important to ensure that the chosen membrane is specifically designed for underground applications and can withstand the unique conditions and pressures associated with being underground.

- Q: Does a waterproofing membrane require any specific cleaning methods?

- Yes, a waterproofing membrane typically requires specific cleaning methods. It is important to avoid using abrasive cleaners or tools that may damage the membrane. Instead, gentle cleaning solutions and soft brushes or cloths should be used to remove dirt and debris without compromising the membrane's integrity. Regular maintenance and cleaning will help prolong the lifespan and effectiveness of the waterproofing membrane.

- Q: Are waterproofing membranes resistant to gasoline?

- Yes, waterproofing membranes are generally resistant to gasoline.

- Q: Can a waterproofing membrane be used on interior walls?

- Yes, a waterproofing membrane can be used on interior walls. Waterproofing membranes are designed to create a barrier against moisture, preventing water from penetrating the surface and causing damage. While they are commonly used on exterior walls to protect against rain and groundwater, they can also be used on interior walls in areas that are prone to moisture, such as bathrooms, kitchens, or basements. By applying a waterproofing membrane, you can effectively protect the interior walls from water damage, mold growth, and other moisture-related issues. It is important to note that the specific type of waterproofing membrane and the proper installation technique should be determined based on the specific needs and conditions of the interior walls. Consulting with a professional or following manufacturer guidelines is recommended to ensure proper application and long-lasting protection.

- Q: Are waterproofing membranes resistant to salt damage?

- Waterproofing membranes are generally resistant to salt damage, as they are specifically designed to create a barrier against moisture and water infiltration, offering protection against saltwater as well. Saltwater can be highly corrosive and cause harm to different materials, but waterproofing membranes are typically constructed using materials that can withstand the corrosive effects of salt. These membranes often consist of reinforced PVC, modified bitumen, or EPDM rubber, all of which have proven their durability and reliability in saltwater environments. In fact, waterproofing membranes are commonly used in areas like basements, swimming pools, and marine structures, where they are regularly exposed to saltwater. Thus, it can be concluded that waterproofing membranes are generally resistant to salt damage and effectively shield against saltwater infiltration.

- Q: How does a waterproofing membrane handle joint or crack movements?

- A waterproofing membrane is designed to handle joint or crack movements by being flexible and accommodating the expansion and contraction of the underlying structure. It can stretch and move with the joints or cracks, ensuring that it remains intact and provides a continuous barrier against water penetration.

- Q: Can a waterproofing membrane be used on sloped roofs?

- Yes, a waterproofing membrane can be used on sloped roofs. In fact, it is often recommended to use a waterproofing membrane on sloped roofs to prevent water infiltration and potential leaks. The membrane acts as a barrier, preventing water from seeping into the roof structure and causing damage. Additionally, the membrane can also help to protect the roof from other elements such as UV rays, temperature fluctuations, and mechanical stresses. It is essential to choose a waterproofing membrane that is specifically designed for sloped roofs and is compatible with the roofing material to ensure long-lasting protection.

Send your message to us

High polymer pp pe pp waterproof membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords