Monolithic Refractories High Performance Ladle Slide Gate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

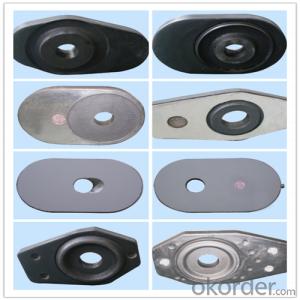

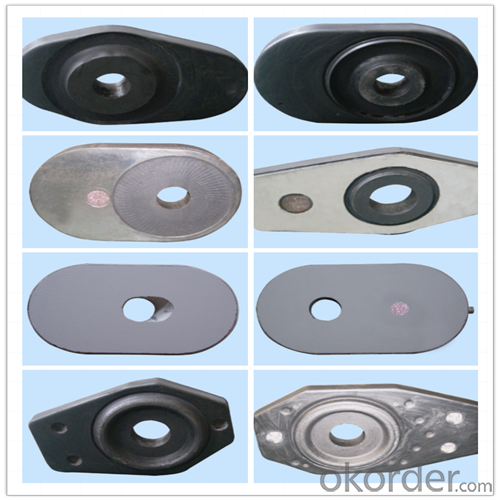

Quick Details for High Performance Refractory Ladle Slide Gate

| Place of Origin: | China (Mainland) | Shape: | Plate | Material: | Alumina Block |

| SiO2 Content (%): | N/A | Al2O3 Content (%): | 80-90% | MgO Content (%): | N/A |

| CaO Content (%): | N/A | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | N/A |

| SiC Content (%): | N/A | Model Number: | CS80 | Brand Name: | |

| Product name: | High performance refractory ladle slide gate | Model No.: | cs80 | Brand name: | CMAX |

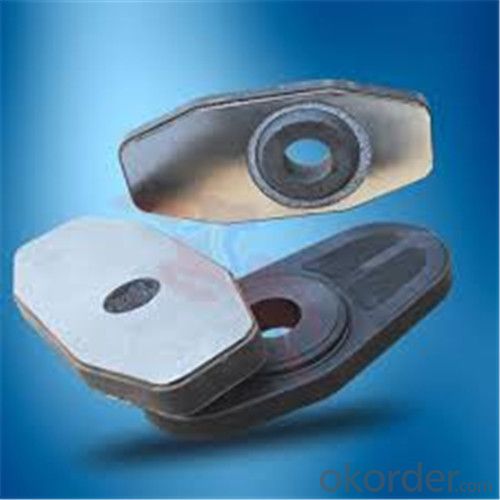

| Quality: | Al-C or Al-Zr-C | Service life: | 4-6 heats | Apparent porosity: | 7% Max |

| Bulk density:: | 3.1 MIN | C.C.S: | 120MPA | MOQ: | 100 pcs for trial |

| Delivery time: | 60 working days upon receipt of deposit |

Packaging & Delivery

| Packaging Details: | Inner carton packing, outer wooden case suitable for long term sea shipping |

| Delivery Detail: | three months working days upon receipt of deposit |

Specifications

Surface flatness less than 0.05mm

High mechanical strength

Erosion resistance

Oxidation resistance

Thermal shock stability

General Chemical Analysis for refractory ladle slide gate :

slide gate plate widely including Alumina carbon and Alumina Zirconia Carbon slide gate plate, MgO and MgO-spinel slide gate plate,nonoxides bonding slide gate plateand unburned slide gate plate.

Alumina -Zirconia-Carbon material

| Al-Zr-C Material | |||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) |

| 85 | 3 | 5 | 7 | 3.1 | 120 |

| 85 | 3 | 4 | 7 | 3.1 | 120 |

Composite type: Al-Zr-C for working line, outer Al-C material

| Al-Zr-C & Al-C Material | ||||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S | |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) | |

| Inner side (Working face) | 85 | 3 | 4 | 7 | 3.1 | 120 |

| Outside | 90 | 3 | 0 | 9 | 3 | |

Sample is on your request.

Welcome to visit our factory~

- Q: What are the key trends in the use of monolithic refractories in the iron and steel industry?

- There are several key trends in the use of monolithic refractories in the iron and steel industry that are worth noting. Firstly, there is a growing demand for monolithic refractories due to their superior performance characteristics compared to traditional brick refractories. Monolithic refractories offer higher thermal shock resistance, better insulation properties, and improved resistance to chemical attacks. This has led to their increased usage in various applications within the iron and steel industry. Secondly, there is a shift towards the use of low-cement and ultra-low cement castables in monolithic refractories. These materials have a reduced cement content, resulting in improved refractory properties such as higher strength, better corrosion resistance, and increased resistance to thermal spalling. This trend is driven by the need to enhance the overall efficiency and durability of refractory linings in iron and steel manufacturing processes. Another important trend is the development of advanced monolithic refractories with enhanced sustainability and environmental performance. The iron and steel industry is under increasing pressure to reduce its carbon footprint and minimize environmental impact. As a result, there is a growing emphasis on the use of environmentally friendly binders and additives in monolithic refractories. These new materials not only offer excellent refractory properties but also contribute to the industry's sustainability goals. Furthermore, there is a rising focus on the development of monolithic refractories that can withstand extreme operating conditions. Iron and steel manufacturing processes involve high temperatures, aggressive chemical environments, and severe mechanical stresses. Therefore, there is a need for monolithic refractories that can endure these harsh conditions without compromising their performance. The industry is investing in research and development to create refractories that provide exceptional resistance to thermal shock, abrasion, and erosion. Lastly, there is an increasing adoption of digital and smart technologies in the monitoring and maintenance of monolithic refractories. With the advancements in sensor technology and data analytics, it is now possible to collect real-time data on the condition and performance of refractory linings. This allows for proactive maintenance, early detection of potential issues, and optimization of refractory usage, resulting in improved operational efficiency and cost savings. In conclusion, the key trends in the use of monolithic refractories in the iron and steel industry include the demand for superior performance, the shift towards low-cement and ultra-low cement castables, the development of sustainable materials, the focus on extreme operating conditions, and the adoption of digital and smart technologies for monitoring and maintenance. These trends reflect the industry's continuous efforts to enhance the efficiency, durability, and environmental sustainability of refractory linings in iron and steel manufacturing processes.

- Q: How do monolithic refractories improve the efficiency of reheating furnaces in steel plants?

- The efficiency of reheating furnaces in steel plants is greatly improved by the use of monolithic refractories. Specifically designed to withstand high temperatures and harsh conditions, these refractories are an ideal choice for steel plants. One important way in which monolithic refractories enhance furnace efficiency is by decreasing heat loss. With their excellent insulation properties, these refractories minimize the transfer of heat from the furnace to its surroundings. As a result, less energy is wasted and the furnace can maintain its desired temperature more effectively. Furthermore, monolithic refractories contribute to a more uniform and controlled distribution of heat within the furnace. They can be easily shaped and installed to create a seamless lining, ensuring that heat is evenly spread throughout the furnace chamber. This even distribution of heat eliminates any hotspots or cold spots, resulting in a more efficient heating process. Another crucial role of monolithic refractories is reducing downtime and maintenance requirements. Unlike traditional brick linings, which are prone to cracking and erosion, monolithic refractories offer superior resistance to wear and tear. This increased durability reduces the need for frequent repairs and replacements, allowing for uninterrupted furnace operation and increased overall efficiency. Moreover, monolithic refractories help improve energy efficiency by decreasing fuel consumption. The superior insulation properties of these refractories help retain heat within the furnace, reducing the amount of energy needed to maintain the desired temperature. This leads to significant energy savings for steel plants, as less fuel is required to achieve the same heating results. In conclusion, the efficiency of reheating furnaces in steel plants is significantly enhanced by the use of monolithic refractories. These refractories reduce heat loss, ensure uniform heat distribution, minimize downtime and maintenance, and decrease fuel consumption. By incorporating these refractories into their furnace linings, steel plants can increase productivity, reduce energy costs, and improve overall operational efficiency.

- Q: How are monolithic refractories used in the repair and maintenance of ladles and tundishes?

- The steel industry extensively utilizes monolithic refractories for the repair and maintenance of ladles and tundishes. These refractories are specifically designed to endure the extreme conditions encountered during the steelmaking process, including high temperatures, thermal shock, and chemical erosion. In the case of ladle repair, monolithic refractories are employed to line the inner walls. Ladles are exposed to intense heat and corrosive molten metal, and the refractory lining serves as insulation and protection against these harsh circumstances. Additionally, the lining helps to maintain the desired temperature of the molten metal, ensuring it remains in an appropriate state for processing. Regarding tundishes, monolithic refractories are used to line the bottom, sides, nozzle, and impact pad. Tundishes are responsible for distributing molten metal to multiple casting molds and are subject to high temperatures and thermal shocks. The refractory lining helps to sustain the necessary temperature and prevent any leakage of molten metal. During the repair and maintenance process, monolithic refractories are applied as dense, high-strength materials that are easy to shape and install. They can be formed into various shapes, such as bricks, castables, and gunning mixes, depending on the specific requirements of the ladle or tundish. These refractories are frequently applied using specialized techniques, such as gunning or casting, to ensure proper adhesion and durability. In addition to their thermal and chemical resistance properties, monolithic refractories also possess excellent mechanical strength and resistance to abrasion. This is particularly crucial in ladles and tundishes, as they experience constant wear and tear from the movement of molten metal and the handling of refractory materials during repair and maintenance. Overall, monolithic refractories play a vital role in the repair and maintenance of ladles and tundishes in the steel industry. They provide the necessary insulation, protection, and durability required to withstand the demanding conditions of steelmaking.

- Q: How do monolithic refractories contribute to the efficiency of iron and steel production?

- Monolithic refractories play a critical role in improving the efficiency of iron and steel production processes. These refractories are renowned for their superior thermal properties, high resistance to mechanical stress, and outstanding resistance to chemical corrosion. One primary manner in which monolithic refractories enhance the efficiency of iron and steel production is by providing effective insulation. By lining furnaces and other high-temperature equipment, monolithic refractories prevent heat loss and ensure consistent maintenance of desired temperatures. This insulation helps reduce energy consumption by minimizing heat wastage, ultimately resulting in cost savings. Moreover, monolithic refractories offer exceptional resistance to thermal shock. In the iron and steel industry, frequent heating and cooling cycles are common, and conventional refractory materials may crack or fail under these conditions. However, monolithic refractories can endure rapid temperature fluctuations without failure, guaranteeing the longevity and reliability of the refractory lining. This resistance to thermal shock reduces downtime for repairs and maintenance, thereby increasing overall production efficiency. Furthermore, monolithic refractories exhibit significant resistance to chemical corrosion. In iron and steel production, various corrosive substances such as molten metal, slag, and gases are present. By utilizing monolithic refractories as lining materials, the underlying structures are protected from chemical attack, preventing erosion and prolonging the equipment's service life. This corrosion resistance reduces the need for frequent repairs or replacements, leading to cost savings and enhanced productivity. Additionally, monolithic refractories offer easy installation and repair. Unlike traditional refractories, which are often constructed brick by brick, monolithic refractories are applied as a single mass. This allows for faster installation and reduces the potential for weak points or joints that may compromise the overall efficiency of the refractory lining. Furthermore, when repairs or maintenance are necessary, monolithic refractories can be easily patched or replaced, minimizing downtime and ensuring seamless operation. To summarize, the use of monolithic refractories in iron and steel production contributes to increased efficiency in multiple ways. Their outstanding thermal insulation properties reduce energy consumption, while their resistance to thermal shock and chemical corrosion ensures reliable and long-lasting refractory linings. Additionally, their easy installation and repair capabilities further enhance productivity. Overall, monolithic refractories are an indispensable component in improving the efficiency and sustainability of iron and steel production processes.

- Q: What are the factors affecting the thermal expansion of monolithic refractories?

- The thermal expansion of monolithic refractories is influenced by several factors. These factors include the chemical composition of the refractory material, particle size, temperature, thermal history, porosity, binder content, and thermal shock. 1. The thermal expansion of the refractory material is significantly influenced by its chemical composition. Different chemical elements and compounds have varying coefficients of thermal expansion. For instance, materials with high levels of silica generally have lower coefficients of thermal expansion compared to those with higher concentrations of alumina. 2. The particle size distribution of the refractory material can also impact its thermal expansion. Smaller particle sizes result in higher thermal expansion due to increased surface area and greater particle contact. 3. The temperature at which the monolithic refractory is exposed plays a crucial role in its thermal expansion. As the temperature increases, the particles gain more kinetic energy, leading to increased movement and expansion. Different refractory materials exhibit significant expansion within specific temperature ranges. 4. The thermal history of the refractory material, including its heating and cooling cycles, can influence its thermal expansion behavior. Repeated heating and cooling cycles can induce microstructural changes in the material, affecting its thermal expansion properties. 5. The porosity of the monolithic refractory also affects its thermal expansion. Higher porosity generally results in higher thermal expansion due to the presence of voids and gaps within the material. 6. The type and amount of binder used in monolithic refractories impact their thermal expansion. Different binders have different coefficients of thermal expansion, which can influence the overall expansion behavior of the material. 7. Rapid temperature changes, such as quenching or exposure to alternating heating and cooling, can cause thermal shock in the refractory material. This can lead to cracks, spalling, and changes in thermal expansion behavior. Understanding these factors is essential when selecting the appropriate monolithic refractory material for specific applications. The thermal expansion characteristics directly affect the performance and longevity of the refractory in high-temperature environments.

- Q: How do monolithic refractories withstand thermal shock?

- Monolithic refractories possess unique properties and composition that enable them to endure thermal shock. Thermal shock occurs when there is a sudden alteration in temperature, leading to stress and potential damage to the refractory material. However, monolithic refractories are constructed to possess high resistance to thermal shock, and this is accomplished through various mechanisms. Firstly, the composition of monolithic refractories incorporates materials with low coefficients of thermal expansion. This implies that they undergo minimal alterations in size or volume when exposed to varying temperatures. This characteristic allows the refractory material to withstand thermal shock by minimizing the stress caused by temperature fluctuations. Secondly, monolithic refractories exhibit exceptional thermal conductivity. This quality enables them to efficiently transfer heat away from the hot regions, preventing localized overheating and diminishing the likelihood of thermal shock. The rapid dissipation of heat aids in maintaining a more even distribution of temperature within the refractory material, thereby reducing the chances of cracking or spalling. Furthermore, the binding agents employed in monolithic refractories play a vital role in enhancing their resistance to thermal shock. These binders provide strength to the refractory material and assist in preserving its integrity during thermal cycling. Additionally, the binders contribute to the refractory's ability to withstand thermal shock by reducing the permeability of the material, thus preventing the infiltration of hot gases or liquids that could cause damage. Moreover, the installation technique of monolithic refractories plays a significant role in their capacity to endure thermal shock. Typically, monolithic refractories are applied as a single, uninterrupted layer, eliminating the weak points such as joints and seams that exist in other refractory systems. This seamless installation method ensures superior resistance to thermal shock as there are no vulnerable points for cracks to propagate. In conclusion, monolithic refractories effectively withstand thermal shock through a combination of factors including their low coefficients of thermal expansion, high thermal conductivity, appropriate binding agents, and seamless installation techniques. These properties and design considerations enable monolithic refractories to proficiently handle rapid temperature changes and maintain their structural integrity, making them ideal for applications involving thermal cycling and extreme variations in temperature.

- Q: How do monolithic refractories prevent heat loss through radiation?

- Monolithic refractories prevent heat loss through radiation by their high thermal conductivity and low thermal expansion. These properties allow them to efficiently transfer heat from the hot side of the refractory to the cooler side, minimizing the temperature difference and reducing heat loss through radiation. Additionally, monolithic refractories provide a continuous and seamless lining, eliminating gaps and cracks that could allow heat to escape. The dense and compact structure of monolithic refractories also acts as a barrier to prevent radiation heat transfer. Overall, monolithic refractories play a crucial role in maintaining thermal insulation and preventing heat loss through radiation in various high-temperature applications.

- Q: How do monolithic refractories provide thermal insulation in the iron and steel industry?

- Monolithic refractories play a crucial role in providing thermal insulation in the iron and steel industry. These refractories are commonly used to line the furnaces and other high-temperature equipment used in the production processes. One way monolithic refractories provide thermal insulation is by their ability to withstand high temperatures without degrading or melting. They are designed to have high heat resistance, which allows them to be used in environments where temperatures can reach several thousand degrees Celsius. By withstanding these extreme temperatures, the refractories prevent the transfer of heat to the surrounding structure, thus providing insulation. Another way monolithic refractories provide thermal insulation is through their low thermal conductivity. These materials have a low thermal conductivity, meaning they are not efficient in conducting heat. Instead, they trap the heat within their structure and minimize its transfer to the surrounding equipment or environment. This characteristic helps to maintain the temperature inside the furnaces and other high-temperature equipment, allowing for efficient and controlled metal production. Furthermore, monolithic refractories can be applied as a thick lining layer, which creates an additional barrier between the high-temperature environment and the surrounding equipment. The thickness of the refractory lining helps to minimize heat transfer and acts as a buffer, reducing the impact of high temperatures on the structural integrity of the equipment. In addition to providing thermal insulation, monolithic refractories also offer excellent resistance to chemical attack and mechanical wear, which are common challenges in the iron and steel industry. This resistance ensures the longevity of the refractory lining, allowing for consistent and reliable insulation over time. Overall, monolithic refractories provide thermal insulation in the iron and steel industry through their high-temperature resistance, low thermal conductivity, thick lining layer, and resistance to chemical attack and mechanical wear. These properties contribute to maintaining the desired temperature inside the equipment and protecting the surrounding structure from the intense heat generated during metal production processes.

- Q: How do monolithic refractories improve energy efficiency in the iron and steel industry?

- Monolithic refractories improve energy efficiency in the iron and steel industry by providing better insulation and reducing heat loss. They have lower thermal conductivity compared to traditional refractory bricks, which means less heat is conducted through the lining of the furnaces or kilns. This leads to reduced energy consumption and improved thermal efficiency. Additionally, monolithic refractories offer better resistance to thermal shock, minimizing the need for frequent repairs or replacements, thereby saving energy and reducing downtime.

- Q: What are the specific requirements of monolithic refractories for soaking pit applications?

- Monolithic refractories for soaking pit applications must meet several specific requirements. Firstly, they need to withstand high temperatures and thermal cycling. This means they must be able to endure temperatures exceeding 1500 degrees Celsius without significant degradation. The longevity and durability of the refractories depend on this capability. Secondly, the refractories must have good thermal shock resistance. Since soaking pits often experience rapid changes in temperature, the refractories must be able to handle these fluctuations without cracking or spalling. This is vital to maintain the refractories' integrity. Chemical attacks are another concern in soaking pit applications. Molten metal, slag, and other corrosive substances are present, so the refractories must have excellent chemical resistance. This prevents erosion and chemical reactions. Withstanding the corrosive effects of molten metal and slag, as well as potential chemical reactions, is crucial. Furthermore, mechanical stresses, such as abrasion and impact, occur in soaking pits due to the movement and handling of metal ingots. The monolithic refractories should possess good mechanical strength and abrasion resistance to withstand these stresses. They should be able to resist wear and tear caused by heavy loads and avoid any mechanical failure. Lastly, the refractories used in soaking pits should be easy to work with and install. This ensures efficient and effective lining of the pit, minimizing any gaps or cracks that could lead to heat loss or chemical penetration. In summary, monolithic refractories for soaking pit applications must meet specific requirements regarding high temperature resistance, thermal shock resistance, chemical resistance, mechanical strength, and ease of installation. Fulfilling these requirements guarantees that the refractories can withstand the harsh conditions of soaking pits and maintain their performance and integrity over an extended period.

Send your message to us

Monolithic Refractories High Performance Ladle Slide Gate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords