Monolithic Refractories for Iron and Steel Industry - High Alumina Based Mortar for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of High Alumina Based Mortar for Hot Blast Stove

FIREF high alumina mortar for hot blast stove made as per international standards, is known for its low thermal conductivity, high refractoriness, and excellent thermal shock resistance.

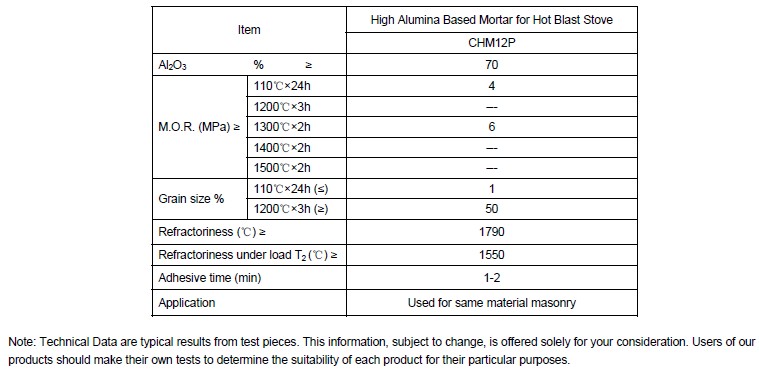

Technical data of High Alumina Based Mortar for Hot Blast Stove

Production line and packing of High Alumina Based Mortar for Hot Blast Stove

Feature of High Alumina Based Mortar for Hot Blast Stove

High refractoriness

Low thermal conductivity

Excellent mechanical strength

Excellent thermal shock resistance

Application of High Alumina Based Mortar for Hot Blast Stove

FIREF high alumina mortar for hot blast stove can be used with the refractory brics of the alike material.

- Q: How do monolithic refractories protect lining in ladles and tundishes?

- Monolithic refractories play a crucial role in protecting the lining in ladles and tundishes through their unique properties and characteristics. These refractories are composed of a single, solid piece, as opposed to traditional brick or tile linings, which consist of individual units. One of the key ways in which monolithic refractories protect the lining is through their high density and low porosity. This property ensures that the refractory material acts as an effective barrier against the penetration of molten metal and slag. By preventing the infiltration of these corrosive substances, the monolithic refractory shields the lining from chemical attack, ensuring its longevity and performance. Additionally, monolithic refractories have excellent thermal shock resistance. Ladles and tundishes are subjected to extreme temperature fluctuations during the steelmaking process, as molten metal is poured and then allowed to cool. The ability of monolithic refractories to withstand these rapid temperature changes without cracking or spalling is vital in protecting the lining from thermal damage. Furthermore, monolithic refractories offer superior strength and mechanical properties. Ladles and tundishes are subjected to various mechanical stresses, such as the weight of the molten metal, the movement of the refractory lining during pouring, and the impact of scrap or additives. The robustness of monolithic refractories allows them to withstand these forces, preventing any structural failure or damage to the lining. Another advantage of monolithic refractories is their ease of installation. Unlike brick or tile linings, which require meticulous jointing and careful placement, monolithic refractories can be applied as a single, cohesive layer. This seamless application ensures a uniform protective barrier, eliminating weak points or gaps that could compromise the lining's integrity. In summary, monolithic refractories protect the lining in ladles and tundishes by providing a dense, impermeable barrier against the penetration of molten metal and slag. Their thermal shock resistance, mechanical strength, and easy installation contribute to the overall durability and longevity of the lining, ensuring its effective performance in the demanding steelmaking environment.

- Q: How do monolithic refractories contribute to the overall efficiency of ladle refining processes?

- Monolithic refractories play a crucial role in enhancing the overall efficiency of ladle refining processes. Ladle refining is a critical step in steelmaking, where impurities are removed and alloying elements are added to achieve the desired steel properties. Monolithic refractories, which are unshaped refractory materials, offer several benefits that contribute to the efficiency of this process. Firstly, monolithic refractories provide excellent thermal insulation. Ladle refining processes involve high temperatures, and the refractories' ability to withstand and contain these temperatures is vital. Monolithic refractories have low thermal conductivity, which minimizes heat loss from the ladle. This insulation helps maintain the desired temperature within the ladle, allowing for efficient refining and reducing the energy required for heating. Secondly, monolithic refractories have high resistance to chemical attack and erosion. During ladle refining, the steel is exposed to various chemical reactions and corrosive elements. Monolithic refractories are designed to withstand these harsh conditions, protecting the ladle from chemical attack and erosion. This resistance ensures that the refractories maintain their structural integrity, preventing any contamination of the steel and extending the lifespan of the ladle. Moreover, monolithic refractories offer easy installation and repair. Unlike traditional brick refractories, monolithic refractories can be applied as a single, homogeneous layer, eliminating the need for complex bricklaying techniques. This ease of installation reduces downtime during ladle maintenance and repair, improving the overall efficiency of the refining process. Additionally, monolithic refractories can be easily patched or repaired as needed, further reducing downtime and ensuring continuous operation. In conclusion, monolithic refractories contribute significantly to the overall efficiency of ladle refining processes. Their exceptional thermal insulation properties, resistance to chemical attack and erosion, and ease of installation and repair all play a vital role in enhancing the efficiency and productivity of ladle refining. By providing a reliable and durable lining for the ladle, monolithic refractories help maintain the desired temperature, prevent contamination, and minimize downtime, ultimately improving the quality and yield of the refined steel.

- Q: How do monolithic refractories resist chemical attacks from molten metals and slag?

- Monolithic refractories are specifically designed to resist chemical attacks from molten metals and slag. They possess several key characteristics that enable them to withstand these aggressive environments. Firstly, monolithic refractories are composed of high-quality materials that have excellent chemical resistance. These materials, such as alumina, magnesia, and chrome, have a high melting point and are stable even when exposed to extreme temperatures and corrosive substances. This chemical stability ensures that the refractory can maintain its integrity and structural strength when in contact with molten metals and slag. Secondly, monolithic refractories have a dense and compact structure. This microstructure helps to prevent the penetration of molten metals and slag into the refractory material. The dense structure acts as a barrier, limiting the contact between the corrosive substances and the refractory. This reduces the chances of chemical reactions and erosion, thereby enhancing the resistance of the refractory to chemical attacks. Furthermore, monolithic refractories often contain additives and binders that enhance their chemical resistance. These additives create a protective layer on the refractory surface, acting as a shield against chemical attacks. They can also react with certain corrosive substances, forming stable compounds that further resist the penetration and corrosion of the refractory material. Additionally, monolithic refractories are designed to have low porosity. This low porosity minimizes the absorption of molten metals and slag, preventing them from infiltrating the refractory and causing damage. By reducing the permeability of the material, the refractory can maintain its structural integrity and resist chemical attacks over prolonged periods. In conclusion, monolithic refractories resist chemical attacks from molten metals and slag through their high-quality materials, dense structure, additives, and low porosity. These combined properties allow the refractories to withstand aggressive environments and maintain their performance and longevity in industrial applications.

- Q: How do monolithic refractories withstand high temperatures and thermal shocks?

- Due to their unique composition and design, monolithic refractories possess the ability to endure high temperatures and thermal shocks. These refractories, referred to as "monolithic" due to their single-piece or structured form, can withstand extreme heat and sudden temperature changes commonly experienced in high-temperature applications. The utilization of high-quality raw materials is a key factor enabling monolithic refractories to withstand high temperatures. These materials are meticulously chosen for their heat and thermal stress resistance. Common components include silica, alumina, magnesia, and other refractory minerals with high melting points. Furthermore, the manufacturing process plays a vital role in enhancing the thermal resistance of monolithic refractories. The raw materials are blended with binders, such as clay or cement, to create a homogeneous mixture. This mixture is then shaped and installed in its final position, either through pouring or gunning, depending on the application. The binder ensures that the refractory maintains its shape and integrity during thermal cycling. In addition, monolithic refractories exhibit excellent thermal conductivity and low thermal expansion properties. This enables efficient heat transfer and dissipation, minimizing the risk of thermal stress and cracking. The low thermal expansion also reduces the likelihood of spalling or delamination, which is crucial for withstanding thermal shocks. Another contributing factor to the high-temperature resistance of monolithic refractories is their ability to form a protective layer or slag on the surface. This layer acts as a barrier, preventing direct contact between the refractory and corrosive materials or aggressive atmospheres. It significantly improves the refractory's longevity and resistance to thermal shocks. Overall, the combination of high-quality raw materials, meticulous manufacturing techniques, and advantageous thermal properties allows monolithic refractories to endure high temperatures and thermal shocks. These refractories find extensive use in various industries, including steel, cement, glass, and petrochemical, as reliable linings in furnaces, kilns, and other high-temperature equipment.

- Q: How do monolithic refractories withstand high temperatures in iron and steel processing?

- Due to their unique composition and design, monolithic refractories have the capability to endure high temperatures in iron and steel processing. Unlike refractories composed of multiple layers, these refractories are made from a single, solid material, which grants them superior thermal conductivity and resistance to thermal shock. One crucial factor that enables monolithic refractories to withstand high temperatures is their high melting point. Typically composed of materials like alumina, magnesia, silica, or zirconia, these refractories possess melting points that exceed the temperatures encountered in iron and steel processing. This ensures that the refractories do not deteriorate or melt when exposed to such extreme temperatures. Additionally, monolithic refractories exhibit excellent thermal insulation properties. With low thermal conductivity, they effectively impede heat transfer from the hot molten metal or gases to the surrounding environment. This insulation property helps sustain high temperatures within the processing units, ensuring efficient and effective iron and steel production. Another significant aspect contributing to the ability of monolithic refractories to withstand high temperatures is their resistance to thermal shock. In iron and steel processing, rapid temperature changes are frequent, which can lead to cracking or spalling in traditional refractories. However, monolithic refractories possess a more homogeneous structure and greater flexibility, enabling them to endure these sudden temperature fluctuations without significant damage. Apart from their composition, the installation method of monolithic refractories also plays a role in their ability to withstand high temperatures. Typically, these refractories are installed using a technique called gunning or shotcreting, where a mixture of refractory material and water is sprayed onto the surface, forming a dense and solid lining. This installation method ensures a strong bond between the refractory and the substrate, enhancing the overall strength and durability of the lining. Overall, monolithic refractories can withstand high temperatures in iron and steel processing due to their high melting point, excellent thermal insulation properties, resistance to thermal shock, and proper installation techniques. These refractories are essential in maintaining the integrity and efficiency of the processing units, facilitating the production of high-quality iron and steel products.

- Q: How are monolithic refractories different from conventional refractories?

- Monolithic refractories differ from conventional refractories in several ways. Firstly, conventional refractories are typically made from pre-formed shapes such as bricks or tiles, while monolithic refractories are unshaped and can be installed by casting, gunning, or ramming. This allows for greater flexibility in design and installation, as monolithic refractories can be shaped to fit any complex geometry or size requirement. Secondly, monolithic refractories have a higher degree of thermal shock resistance compared to conventional refractories. This means that they can withstand rapid changes in temperature without cracking or spalling. This property is particularly important in applications where the refractory is exposed to extreme temperature variations, such as in furnaces or kilns. Furthermore, monolithic refractories have superior corrosion resistance, which makes them more suitable for environments with acidic or alkaline conditions. They are also known for their excellent mechanical strength and abrasion resistance, making them ideal for applications where the refractory is subjected to high mechanical stresses or wear. Lastly, monolithic refractories offer better energy efficiency due to their lower thermal conductivity. This means that they can retain heat more effectively, resulting in reduced energy consumption and cost savings. Overall, the main differences between monolithic refractories and conventional refractories lie in their installation methods, thermal shock resistance, corrosion resistance, mechanical strength, and energy efficiency. These factors make monolithic refractories a preferred choice in many industrial applications where flexibility, durability, and performance are crucial.

- Q: What are the typical compositions of monolithic refractories?

- Typically, monolithic refractories consist of a combination of aggregates, binders, and additives. Aggregates, such as alumina, magnesia, or silicon carbide, provide the main refractory properties and are chosen based on the desired characteristics of the refractory, such as resistance to high temperatures, thermal shock, or chemical attack. To bind the aggregates together and give the refractory its shape and strength, binders are used. Common binders include clay, calcium aluminate cement, or colloidal silica. The binder also impacts the overall performance of the refractory, affecting properties like thermal conductivity and chemical resistance. Additives are often included in the composition of monolithic refractories to improve specific properties or facilitate the processing. These additives can be plasticizers, which enhance workability and make installation easier, or antioxidants, which enhance the refractory's resistance to oxidation. Ultimately, the specific composition of a monolithic refractory can vary depending on the intended application and desired performance characteristics. Different combinations of aggregates, binders, and additives can be customized to meet specific temperature ranges, chemical environments, or mechanical stresses.

- Q: How do monolithic refractories prevent heat loss through radiation?

- Monolithic refractories prevent heat loss through radiation by forming a continuous and seamless layer that acts as a barrier to thermal radiation. This layer reflects and absorbs the radiant heat, preventing it from escaping and thus minimizing heat loss. Additionally, the high thermal conductivity of monolithic refractories allows them to efficiently conduct and distribute heat, further reducing the potential for radiation heat loss.

- Q: How do monolithic refractories contribute to the safety of iron and steel plants?

- Monolithic refractories play a crucial role in ensuring the safety of iron and steel plants. These refractories are specially designed to withstand high temperatures, chemical attacks, and mechanical stresses commonly encountered in these industrial settings. By utilizing monolithic refractories, iron and steel plants can benefit in the following ways: 1. Thermal resistance: Monolithic refractories have excellent resistance to extreme temperatures, preventing heat loss and ensuring the efficient operation of various equipment and systems. This thermal insulation contributes to the safety of the plant by reducing the risk of overheating, which could lead to equipment failure or even catastrophic accidents. 2. Chemical resistance: Iron and steel plants involve the use of various chemicals, including molten metal, slag, and corrosive gases. Monolithic refractories exhibit high resistance to these aggressive chemical environments, preventing corrosion, erosion, and material degradation. This resistance ensures the integrity of refractory linings, reducing the risk of leaks, spills, and contamination that could jeopardize the safety of workers and the environment. 3. Structural stability: Monolithic refractories provide excellent mechanical strength, offering structural stability to the linings of furnaces, ladles, and other equipment. This stability is crucial for the safe operation of iron and steel plants, as it minimizes the risk of structural failure, collapse, or damage caused by mechanical stresses or heavy loads. 4. Rapid repair and maintenance: Monolithic refractories offer the advantage of easy installation and repair compared to traditional brick refractories. Their application involves pouring, gunning, or ramming the refractory material in place, which allows for quick repairs and maintenance. This rapid response to refractory failures or damages contributes to the plant's safety by minimizing downtime and preventing potential hazards associated with equipment malfunction. 5. Flexibility and adaptability: Monolithic refractories can be tailored to meet the specific needs and requirements of iron and steel plants. They can be customized in terms of composition, density, thermal conductivity, and other properties, allowing for optimal performance under varying operating conditions. This adaptability ensures that refractory linings are well-suited for the plant's processes, reducing the likelihood of accidents or incidents caused by inadequate refractory materials. In summary, monolithic refractories enhance the safety of iron and steel plants by providing thermal resistance, chemical resistance, structural stability, rapid repair capabilities, and flexibility. By utilizing these refractories, iron and steel plants can maintain a safe working environment, minimize the risk of accidents, and ensure the reliable operation of their equipment and systems.

- Q: What are the typical properties of monolithic refractories used in iron and steel industry?

- Monolithic refractories used in the iron and steel industry generally possess several key properties that make them suitable for the harsh operating conditions in these industries. Firstly, monolithic refractories have excellent thermal shock resistance. They can withstand rapid temperature changes without cracking or spalling, which is crucial in the iron and steel industry where the heating and cooling processes can be highly intense. Secondly, these refractories exhibit high refractoriness, meaning they can withstand extremely high temperatures without losing their strength or shape. This is essential in environments where temperatures can reach well above 1000 degrees Celsius. Additionally, monolithic refractories used in the iron and steel industry are known for their excellent corrosion resistance. They can resist the corrosive effects of molten metals, slags, and gases that are commonly encountered in these industrial processes. Furthermore, these refractories have good mechanical strength and abrasion resistance, allowing them to withstand the physical stresses and wear caused by handling and mechanical operations. Another important property of monolithic refractories is their ability to form strong bonds with the existing refractory lining. This ensures a secure and long-lasting installation, reducing the risk of failure and minimizing downtime for maintenance or repairs. Lastly, these refractories often have low porosity, which prevents the infiltration of molten metal or slag into the lining. This helps to maintain the integrity of the refractory structure and prolong its service life. Overall, the typical properties of monolithic refractories used in the iron and steel industry include thermal shock resistance, high refractoriness, corrosion resistance, mechanical strength, strong bonding, and low porosity. These properties collectively contribute to the efficient and reliable operation of iron and steel manufacturing processes.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Monolithic Refractories for Iron and Steel Industry - High Alumina Based Mortar for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords