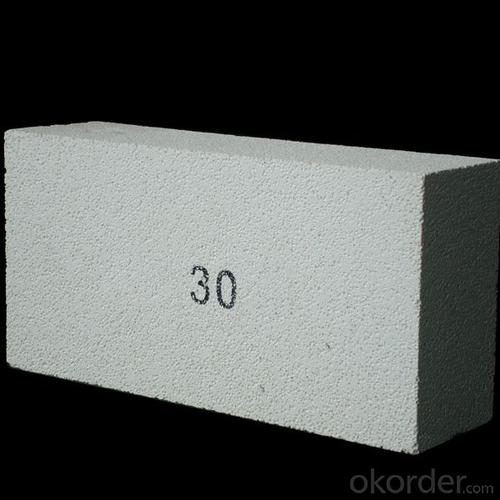

High-Performance Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Pcs m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulating Fire Brick

Our insulating firebricks are classified under temperature range from 1300℃ to 1700℃.Our insulating fire bricks are manufactured from high purity alumina clay.

Feature of Insulating Fire Brick

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application of Insulating Fire Brick

Our insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

Technical Data of of Insulating Fire Brick

- Q: Are insulating fire bricks resistant to thermal shock cracking?

- Yes, insulating fire bricks are resistant to thermal shock cracking. These bricks are specifically designed to withstand high temperatures and rapid changes in temperature without cracking. They have a low thermal conductivity, which means they can effectively trap and retain heat without being damaged by thermal shock. Insulating fire bricks are often used in applications where thermal shock is a concern, such as in furnaces, kilns, and other high-temperature environments. Their resistance to thermal shock cracking makes them a reliable choice for these types of applications.

- Q: Can insulating fire bricks be used in ceramic industry kilns?

- Yes, insulating fire bricks can be used in ceramic industry kilns. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in kilns where high heat retention and energy efficiency are important.

- Q: Are insulating fire bricks resistant to flame impingement?

- Yes, insulating fire bricks are resistant to flame impingement.

- Q: Can insulating fire bricks be used in the construction of ceramic fiber kilns?

- In the construction of ceramic fiber kilns, insulating fire bricks can indeed be utilized. These bricks are specifically designed to offer thermal insulation and minimize heat loss in high-temperature situations. Their exceptional insulating properties, characterized by low thermal conductivity, render them extremely suitable for maintaining elevated temperatures in kilns. The incorporation of insulating fire bricks in ceramic fiber kiln construction has the potential to heighten the kiln's overall energy efficiency and enhance its performance. However, it is crucial to guarantee that the insulating fire bricks selected align with the particular requirements and operating conditions of the ceramic fiber kiln to achieve optimal outcomes.

- Q: Are insulating fire bricks resistant to oil and gas?

- Yes, insulating fire bricks are generally resistant to oil and gas. These bricks are designed to withstand high temperatures and are commonly used in applications where they may come into contact with oil and gas, such as furnaces and kilns. However, it is important to note that the specific type and composition of the fire bricks can affect their resistance, so it is always recommended to consult the manufacturer's specifications for detailed information.

- Q: Are insulating fire bricks resistant to phosphoric acid?

- Phosphoric acid, being a strong acid, has the potential to react with and corrode various materials, including fire bricks. Although certain fire bricks may possess a degree of resistance to acidic conditions, insulating fire bricks are generally not equipped to endure prolonged exposure to phosphoric acid without experiencing notable deterioration. As a result, it is advisable to employ acid-resistant materials like acid-resistant bricks or linings when handling phosphoric acid or other potent acids.

- Q: Can insulating fire bricks be used in the construction of ovens or kilns for pottery?

- Insulating fire bricks are capable of being used in the construction of ovens or kilns for pottery. These bricks are specifically engineered to endure high temperatures and possess exceptional insulation qualities. With their low thermal conductivity, they effectively retain heat and prevent heat loss, making them highly suitable for establishing and maintaining the elevated temperatures necessary for pottery ovens or kilns. Furthermore, these bricks exhibit excellent resistance to thermal shock, enabling them to endure sudden temperature fluctuations without fracturing or shattering. Consequently, they are a dependable option for constructing ovens or kilns that undergo frequent cycles of heating and cooling. Overall, due to their thermal insulation properties and durability, insulating fire bricks are widely favored in the construction of pottery ovens or kilns.

- Q: Are insulating fire bricks resistant to sulfur dioxide?

- In general, insulating fire bricks do not possess resistance against sulfur dioxide. This highly corrosive gas can undergo reactions with the components of insulating fire bricks, resulting in their deterioration and diminished efficiency. Therefore, it is crucial to utilize refractory materials that are specifically engineered to endure exposure to sulfur dioxide, whenever such a requirement exists for the intended application.

- Q: If there is a main component of cenosphere light insulating brick.

- Light heat insulation brick with cenosphere composition, material properties will be more high, especially the main properties of thermal conductivity

- Q: Can insulating fire bricks be used in crucibles?

- Yes, insulating fire bricks can be used in crucibles. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in crucibles where extreme heat is required.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 5 Million |

| Main Markets | 10.00% Northern Europe 30.00% North America 30.00% Eastern Asia 5.00% Africa 10.00% Southeast Asia 15.00% Western Europe |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 10 |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 16,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

High-Performance Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Pcs m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords