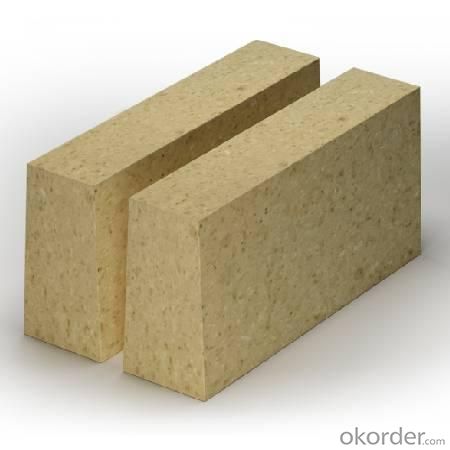

High Alumina Brick - Standard and Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

CNBM fire brick is an alumina-silicate refractory material in which the Al2O3 content is more than 55%, and is calcined from a high-content alumina raw material such as a silicone raw material or a bauxite. High heat resistance and high temperature resistance at 1770 ° C and above. Has good slag resistance, mainly used in the masonry of steelmaking electric furnace, glass furnace, cement rotary furnace and so on.

Standard sizing: 230 x 114 x 65 mm ,Special size and OEM Product Data Service also provide!

Packing and Shipping

Packaging : Fire brick Packed by sea-worthy wooden pallet + shrink wrapped + carton

For example, Standard size of refractory brick : 230x114x65mm

Shipping : 384pcs/plt x 18plts in one 20 feet container;

Common Product Data:

project | first-class | Second class | Third class | highest |

LZ-75 | LZ-65 | LZ-55 | LZ-80 | |

AL2O3 %≥ | 75 | 65 | 55 | 85 |

Fe203 % < | 2.5 | 2.5 | 2.6 | 2.0 |

Bulk Density g/cm³ | 2.5 | 2.4 | 2.3 | 2.6 |

Cold Crushing Strength MPa > | 70 | 60 | 50 | 80 |

Refractoriness Under Load ℃ | 1510 | 1460 | 1420 | 1550 |

Refractory temperature ℃ > | 1790 | 1770 | 1770 | 1790 |

Apparent Porosity % < | 22 | 23 | 24 | 21 |

Refiring linear change % | -0.3 | -0.4 | -0.4 | -0.2 |

Products Pics

Why us

Professional fire brick manufacturer. We have being specialized in producing refractory fireclay brick for more than 40 years so that we can guarantee a stable quality.

Guaranteed quality. Our production process conforms strictly to the requirements of ISO9000 quality management system. Quality inspection is carried out in every links of our production. SGS third party inspection is available.

Sound after sales service. We provide sound after sales service. We provide 24 hours’ consultation service. We are ready to answer your consultations at any time.

Main products as follow:

1)Various industrial furnace series refractories

High-alumina brick, anchor brick, clay brick, lightweight insulation brick, high-strength diatomaceous earth brick, low-iron mullite brick, silica brick

2)Heat storage balls for various industrial furnace regenerators

Special corundum heat storage balls, honeycomb, regenerator block, tapping chute brick,Anti-stripping high-alumina bricks for cement industry, alkali-resistant bricks, phosphate bricks, etc.

3)Industrial furnace and power generation boiler industry with various brands of wear-resistant bricks, corundum brick, mullite bricks and other stereotypes.

4)Wear-resistant castables, corundum castables, low-cement high-strength castables, impervious materials, self-flowing materials, plastics, and other unshaped refractories.

Products exported to the United States, India, Japan. South Korea, Pakistan and other countries.

- Q: How much is the bending temperature aluminum silicon carbide brick for torpedo car

- High alumina brick is made of superfine alumina, fused corundum and fused mullite as main refractory materials.

- Q: Is there a big difference between two high alumina brick and one high alumina brick?

- The difference between the two kinds of high alumina bricks is great. I perennial in Zhengzhou was responsible for the production and sale of colt refractories

- Q: What are the grades of high alumina bricks?

- According to the size of high aluminum brick is divided into: standard brick, special-shaped brick.

- Q: What is the content of free silica in the refractory bricks of high alumina bricks?

- In the meantime, the free silica content of silicon brick is as high as 90% above. Therefore, the most serious damage is silicon brick, followed by clay brick, high alumina brick, magnesia brick and so on.

- Q: What are the alloy wear resistance materials?

- According to the composition of Beijing Naimo metal materials company will wear resistant metal materials is divided into the following five categories: one: high manganese steel series: high manganese steel (ZGMn13),

- Q: Which is better, the soft core or the hard core?

- When the current through the wire, it will produce a magnetic field in the vertical plane space of the wire, if there is a current two wire close by in the same direction, because they produce a magnetic field in the direction is opposite, it will produce a repulsive force is due to the magnetic field force. They will mutually inhibit current intensity of the other party, caused by the reduction of current in the wire, this inhibition of each current intensity, we called wire inductance. When the AC current line frequency is high, the inductance is stronger.

- Q: Corundum, high alumina and fireclay refractory difference is what

- Corundum is unknown. The high alumina brick has higher aluminum content than the clay brick, and the temperature resistance is higher than 300 degrees. It is more durable and durable than the clay brick. The production process of high alumina brick is better than that of clay brick. For example, the weight of good clay brick is 3.7kg, and that of high alumina is 4.2kg. Good density. But the price of high aluminum is too high: ordinary clay brick (standard brick example) in 1.1--2.5 yuan / block, high aluminum to 4.5 yuan / block, or even more expensive. The extra high aluminum has reached 5000 tons. Say straight white point is: under the same conditions, clay brick for a period of one year, then the high aluminum for more than three years.

- Q: What is spalling resistant high alumina brick?

- Spalling resistant high alumina brick is a kind of high alumina brick. Antistripping high alumina brick with high grade bauxite and containing Zr02 synthesis as raw material, according to a certain proportion by high pressure molding system in sintering products, products with anti stripping ability, and have the anti erosion potassium, sodium, sulfur, chlorine and alkali salt, low thermal conductivity and other properties that is the transition zone of cement kiln and decomposition of ideal material with remarkable characteristics, the product is good thermal shock resistance, strong ability to adapt to the environment. It is used in the preheating or decomposing furnace, grate cooler and so on.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- High alumina brick clay brick up to 1700 degrees above 1500 degrees -1750 degrees of magnesia brick and magnesia chrome brick 1500-1650 degrees, I is the production of clay brick, brick my temperature at 1500-1700 degrees. Specific depends on what kiln, brick is only part of it

- Q: What is the apparent porosity of high alumina brick?

- Total porosity is porosity refers to the total volume of sample porosity in the percentage of total volume of samples. Apparent porosity refers to the percentage of the total volume of openings, pores, and total specimens in the sample.

Send your message to us

High Alumina Brick - Standard and Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords