HDPE Water Suppply Pipe, Gas Pipe Energy-saving and High Speed Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Water Suppply Pipe, Gas Pipe Energy-saving and High Speed Extrusion Line

Product Description

HDPE Water Suppply Pipe, Gas Pipe Energy-saving and High Speed Extrusion Line Made In China absorbed and digested the advanced production technology home and abroad based on our former round dripper irrigation pipe production line, developed the third generation for this extrusion line. This line has the advantages of high extruding speed, precious punching, better cost-saving and so on.

Packaging & Delivery:

| Packaging Detail: | Best Sea transportion package to avoid damagement |

| Delivery Detail: | 100days |

Advantage:

This production line adopts the most advanced technology of Europe,it is a new research achievement of energy-saving production line,which is suitable for high speed extrusion of HDPE,PP and other polyolefin pipe.

compared with common production line,the energy-saving effect reach on 35%, and the product efficiency increase more than 1 times, thus it is not only saving the cost of site and manpower,but also improving efficiency.

This production line has nice appearance,higher automatical degree ,production reliable and stable

Application:

This production line adopts the most advanced technology of Europe,it is a new research achievement of energy-saving production line,which is suitable for high speed extrusion of HDPE,PP and other polyolefin pipe.compared with common production line,the energy-saving effect reach on 35%, and the product efficiency increase more than 1 times, thus it is not only saving the cost of site and manpower,but also improving efficiency. This production line has nice appearance,higher automatical degree ,production reliable and stable .

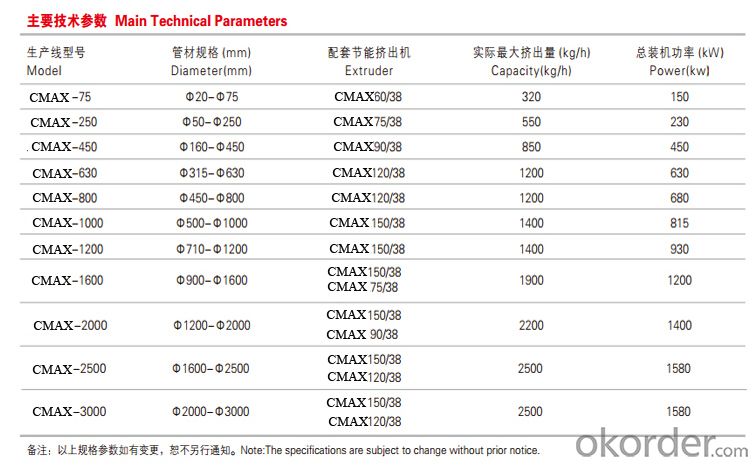

Technical parameters:

FAQ

1., How about the after service?

We have a strong team, special for after service. We can arrange engineers to do service for you.

2. How does your company do regarding quality control?

Quality is priority. We always attach great importance to quality controlling from the beginning.

3. why choose CNBM Group

We are a state-owned company which is a leader in this field(in China). Our quality products and service have enabled us to expand our market from china to more than 60 countries.

4.Q:An extrusion machine how long ?

A single extruder could probably use a long long , It can change a screw when it hurts

5.Q: What's the price of this machine please?

A: Dear customer, for each kind of our machines, we have lots of models. Generally speaking, we design the production lines according to different requirements of different machines from different customers. Therefore, the prices are different. So please kindly inform us your requirements. For example, the raw material, the output product size, capacity and etc. The more detailed, the better. Our Engineers will design a suitable production line for you.

6.What's your company's advantages comparing with other manufacturers?

1) over 20 years experience to provide product with high quality and reasonable price.

2) High output capacity .

3) We can support engineer with overseas training.

4) Professional design team can support with the customized design.

5) Most of electric parts are use the famous/qualified brand, such as Siemens, NSK, etc.

6) Have a team of full experienced technical workers and engineers.

7) Our product passed CE,UV,SGS,etc.certification.

7. Do I have to go to China to check the machine/equipment ?

you can come to China to check the machine and the equipment. .

- Q: What is the waste gas produced by the extruder, granulator and mixer?

- Plastic is a chemical product, and the waste gas produced by the process is organic waste gas. The commonly used and relatively efficient treatment method is activated carbon adsorption. The specific work process is as follows: exhaust gas, air pipe, dry filter, activated carbon adsorption, fan and discharge

- Q: Wire and cable extrusion machine temperature exceeds the process documentation, what are the reasons?

- As far as actual production is concerned, it is necessary to go beyond the regulations to produce normally

- Q: What are the two types of extrusion?

- Extrusion? The extruder. The extruder is divided into single screw extruder and twin screw extruder, and the twin screw extruder is divided into two parts: flat, double and cone.

- Q: Plastic double screw extruder, pumping air will accumulate material, how is it going on?

- Adjust the assembly and check the exhaust block

- Q: PVC extrusion machine extrusion stone floor no pressure, what reason?

- PvC stone floor extruder pressure is adjusted by the screw and die head

- Q: Comparison of injection molding machines and Extruders

- The plastic to replace steel or nonferrous metal, plastic cement, which is widely used in agriculture, building materials, packaging, machinery, electronics, automobiles, household appliances, petrochemical and defense, extruder and daily life other fields. So it can be predicted that in twenty-first Century, the plastic will be one of the most important raw material of human activities. The extruder design due to extrusion molding is the main form of plastic processing, so the development of plastic extrusion molding technology and equipment has important significance. The polymer materials used in blending type mixing equipment modification there are three main types: parallelwith twin-screw extruder, reciprocating screw kneader and series disc extruder. The small corotating twin screw extruder has domestic production can squeeze But tons of large mixing extrusion granulation unit will rely on the import machine technology. At the same time. Reciprocating screw kneader and series disc extruder is a necessary device for preparing high fill and high added value of polymer alloy, the current domestic research on them is just in the prototype stage, specifications, varieties not all, have broad prospects for development.

- Q: Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q: Extrusion machine operating procedures, specific points, thank you!

- 1, operators must be familiar with the procedures, the safety test qualified, wear good protective equipment, shall operate the equipment.2 when the power is on, check whether the thermal control of the electric appliance is sensitive and reliable, whether the thermocouple indicates the temperature is correct or not, and if there is a problem, please repair the personnel to exclude them.3 when driving, should check the main reducer, traction non polar transmission, the line is stepless gear box lubrication is normal, fan ventilation is good.4 before driving, pay attention to the heating temperature of each section, whether the actual temperature required by the process, the heat preservation time should be enough, and the initial heating time can not be less than 3 hours heat preservation.5, not in the plastic bad, scorched, aging, extrusion production, in case of accidents, and found the above problems, immediately try to rule out.

- Q: Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- Can, but need feeding machine and related auxiliary mixing granulator, the cost is not low, but the effect is less than double make flat, because itself is not suitable for the design of double cone, adjustment of the formula is the key.

- Q: How many roots are produced in an hour for an PVC tube extruder?

- It depends on the type of your extruder and the specification of the tube you produced

Send your message to us

HDPE Water Suppply Pipe, Gas Pipe Energy-saving and High Speed Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords