CMAX Large Diameter HDPE Water Supply and Gas Supply Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery:

| Packaging Detail: | Export packing, covered with film for dustproof, wooden crates packing for sea transport |

| Delivery Detail: | 50 days after receiving 30% advanced payment |

Water Supply And Gas Supply HDPE Large Diameter Pipe Production Line

Welcome to visit our Water Supply And Gas Supply HDPE Large Diameter Pipe Production Line!

Application:With this production line you can extrude high quality large diameter water supply and gas supply pipes.

The pipes produced by our line have excellent stiffness and flexibility, resistance to creep deformation,excellent heat-linkage. Large diameter HDPE pipes start to play very important role in the city water and gas supply systems.

Properties and Advantages: The production line consists of control system, extruder,mould, calibration unit, haul-off unit,planetary cutter and stacker.

Downstream equipment:This line is assembled lattice or spiral mould,new type calibration unit and spraying cooling bath. Advanced PLC control system and large chromatic liquid-crystal screen make the operation more convenient, having a friendly human-machine interface.

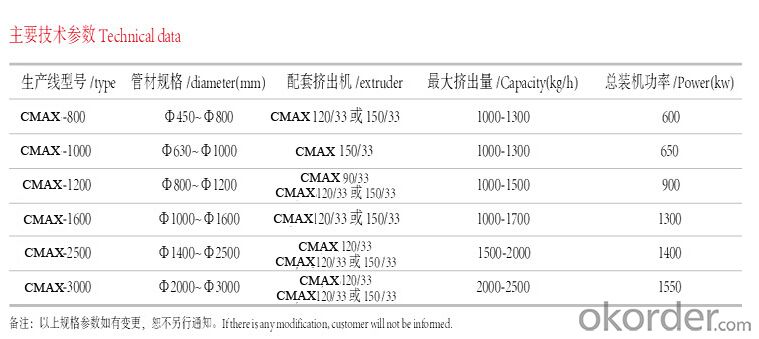

Main Technical Parameters:

Our company can design and manufacture products with different specs for clienteles.

The features:

1, We have set up one special forging team to design –develop-produce-distribute-debug-repair for our clienteles.

2, We possess strong technical power, high-tech, one complete set of checkout equipment, abundant debugging experience and timely after-sale service.

3, The most crucial is that we brave enough to innovate, keep enterprise, keep improving.

If you are interested in our product, please be free to contact us. Whether we could cooperate, we would do our best to help you. I’m confident that will be benefit to you and us!

1. The Extruder:

2.The Die Head:

3.The Vacuum Sizing Water Tank:

4.The Spraying Cooling Water Tank:

5.The Caterpillar Tractor:

6.The Cutter:

7.The Stacker:

8. The HDPE Pipe:

- Q: Basic parameters of extruder screw

- 3, compression ratio epsilon, also known as the geometric compression ratio of screw, is the ratio of the volume of the first screw groove to the volume of the last screw groove at the homogenization section. It is determined by the physical compression ratio of plastics - that is, the density of the product and the density of the performance of the feed. The extruder is relatively compressed, the purpose is to make granular plastics fully plasticized and compacted. The selection of compression ratio should be different when different kinds of processing plastics are used. According to the compression ratio, the types of screw can be divided into three types: equidistant, unequal depth, equal depth, unequal distance, unequal depth, unequal distance. Among them, equidistant and unequal depth is the most common one. This kind of screw is easy to process, the contact area of plastic and cylinder is large, and the effect of heat transfer is good.

- Q: Why is the connection between the extruder and the switchboard?. The upper and lower three terminals are short circuited

- The action should be to require three simultaneous electricalOr a two way backup

- Q: extrusion machine prone to coke material, what is the cause? How to improve or solve?

- Or the outer lubrication part of low molecular weight is replaced by macromolecule lubrication

- Q: Cable extrusion machine 6.57090 machine model how to see, know the master to say, thank you

- Screw diameterAskDo you mean the plastic screw? 90 machines are so long. What's the 90 machine? Thank youChasing the answerDiameter, not length

- Q: Why will the extruder frequency shift stop?

- Because the frequency converter is out of order, you can look at the fault record parameters of the inverter.

- Q: What are the common extrusion molding products?

- A plastic pipe, including water supply and drainage pipe, casing and other electrical B plastic doors and windows just C a variety of wire, cable, cable break, also includes a data line, wire headset D PVC ceiling e for plastic guardrail protection f roadside flowers and some decorative strips, temporary thought so much, there are a lot of specific products and you look at the things around you can think of

- Q: Comparison of injection molding machines and Extruders

- Considerations for extruder use:1, extrusion machine is running forward, avoid reverse2, avoid fasting operation, must heat engine feeding operation, so that can avoid sticking bar (holding shaft) phenomenon3, the extruder inlet, vent hole is strictly prohibited access to iron and other miscellaneous, so as not to cause accidents, affect production4, safe use of electricity, grounding wire5. When the machine is running, it is forbidden to touch the rotating parts such as the material inlet, the material outlet, the belt, the gear and so on6, before using the machine should be injected with lubricating oil, so as not to cause damage to the machineSince the extruder as one of the three synthetic plastic material since the advent of rapid development.

- Q: Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q: Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- because itself is not suitable for the design of double cone, adjustment of the formula is the key.

- Q: Who knows the structure of the big extrusion machine head (has cooled), smash what structure, model of plastic crusher?

- There is a kind of broken engineering material. I wonder if you can find it

Send your message to us

CMAX Large Diameter HDPE Water Supply and Gas Supply Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords