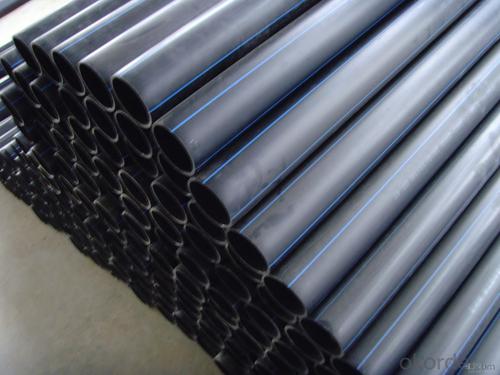

HDPE Plastic Tubes CNBM Manufacturer PVC Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 3000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

ISO 4427 hdpe pipe

1.Manufacture

2.Application:water supply

3.Diameter:20-1000mm

Advantages:

1.Nontoxic:

PE pipe material nontoxic, tasteless,it belongs to green building materials, never scaling,

which can effectively improve the water quality.

2.Corrosion resistance:

High resistance to attack from various types of chemicals. No electrochemical corrosion.

3.No Leakage:

PE pipe is connected in the ways of butt fusion, socket fusion and electrofusion and the

strength of joint point is higher than tube itself .

4.higher flow capacity:

The Smooth inner wall is easy for pipeline transportation .Under the same condition

delivery capacity can be increased by 30%.

5.Convenient for construction and installation:

PE pipe could be installed in a variety of trenchless ways, so it is very convenient for

construction and installation.

6.Lower system and maintenance costs:

PE pipe is not only convenient to transport and install, but also reduce the worker’s

labor intensity and improve work efficiency.

7.Longevity:

50 years under pressure use.

8. Recycled and Environment-friendly

- Q: I recently purchased a 1972 Volkswagen Super Beetle and I found that the plastic tube above the fuel tank is cracked. I know that it is some sort of vapor trapping device, but i cannot find a replacement

- Try duct tape. Seriously. Same thing happened to me on my 73 and it works.

- Q: What's the diameter of the white plastic tube in the kitchen, about 10cm? What should I do if the water leaks?

- Glue bonding: to the building materials shop to buy a small bottle of PVC pipe special glue (other glue is not good), and then find a small piece of suitable PVC pipe fragments, will dew point paste firmly.

- Q: I am trying to design a tube that needs a lid which will have rubber seals. therefore i need to figure out what the series roughness should be on the tube where the rubber seals need to sort of slide in. the tube is about 12.5in long and will be smooth 1.5in in on the inside and the cover goes 1.5in into the tube when put on the tube. This is for work, i am just trying to finish my drawings for this product.

- 63 u/in will be fine.

- Q: Can plastic tubes be customized with color?

- Yes, plastic tubes can be customized with color.

- Q: Are plastic tubes resistant to mold or mildew?

- Yes, plastic tubes are generally resistant to mold or mildew due to their non-porous nature.

- Q: how do i safely clean the inside of used fluorescent tubes in order to use them for a different purpose.?

- Don't do this. The glass is fragile and easily shattered. It contains mercury - not nice stuff to deal with. Get glass tubing or plastic tubing instead.

- Q: What are the toxic hazards in plastic pipe production plants? What are the specific hazards?

- After heating and extrusion molding, the smell is 100%, which is harmful to the body, especially to the liver.

- Q: You know those cheap popsicles that come in a cylindrical plastic bag? They come in big boxes inwhich they are all linked together. When I eat those, I always start coughing, and I've heard a lot of people say the same thing. What is the reason for this?

- never heard of that

- Q: How do you connect the white plastic tube with the PPR tube?

- I don't know. What's the diameter of the white plastic tube?. The small pipe needs joint.Thick pipe, if it is not tap water, pressure is not the case, you can directly white plastic pipe, hot water, wearing gloves, directly inserted into the pipe PPR tube, five cm or so can be.It's better to have a flamethrower, bake the tube and put it in

- Q: Can plastic tubes be used for soundproofing?

- Plastic tubes can be used for soundproofing to some extent, but they are not the most effective option. While they can reduce sound transmission, their ability to dampen and absorb sound is limited compared to other soundproofing materials such as acoustic foam or mass-loaded vinyl.

Send your message to us

HDPE Plastic Tubes CNBM Manufacturer PVC Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 3000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords