HDPE Pipe for Agriculture Irrigation System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 1999999 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

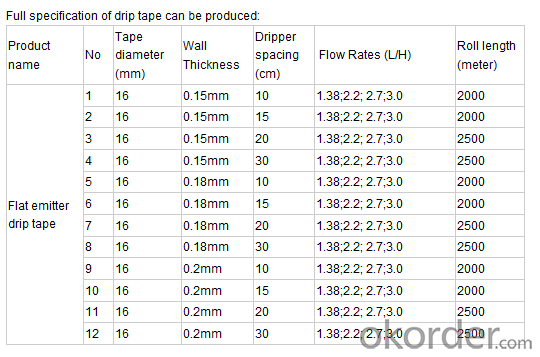

The Application of Irrigation Tape distance 30cm Good Quality:

HDPE Pipe for Agriculture Irrigation System

The layflat hose has a wealth of residential and commercial applications, and it is usually used for general water transfer purposes as well as for submain.Generally layflat hoses are used in the industry of agriculture,in pipe lining and rehabilitation,in removing waste water,in mine dewatering ,in the chemical industry and even for household chores

HDPE Pipe for Agriculture Irrigation System

Features OF HDPE pipe for agriculture irrigation system

1. Seamless drip tape with drippers permanently fixed inside. Seamless construction improves ability to withstand pressure fluctuations.

2. With two parallel blue line helps to ensure upright positioning of the dripper.

3. Manufactured from special grade, virgin polymer ensuring close dimensional tolerance and higher strength even at lower wall thickness.

4. Manufactured with the most modern, state-of-the-art equipment. It’s computerized continuous online quality control ensures reliable quality and consistent performance.

5. Hydraulically designed turbulent flow path emitter with wide cross sectional area and precision inlet filter that makes it a truly clog resistant drip tape.

6. Precision laser drilled outlet holes.

7. Extremely low manufacturing coefficient of variation, CVm ensures high field emission uniformity.

HDPE Pipe for Agriculture Irrigation System

The decription of HDPE pipe for agriculture irrigation system:

Two layers of PVC bonded together encapsulating high tensile polyester fibers.

Thick wall dimensions and strong yarn structure help products to hold connections and resist bursting.

It assumes the conventional round appearance when pressure is being passed through it and then returns to its flat shape after use.It does not need drying and can be rolled immediately after use.

HDPE Pipe for Agriculture Irrigation System

Features of HDPE pipe for agriculture irrigation system:

1.Great durability mainly given by the reinforcement and high-density PVC material.

2.The layflat hoses can have up to 12 inches diameter based on their applications.

3.Extra thickness are added in order to prevent bursting due to pressure in heavy industry.

4.Can be easily rolled up,stored and reused,as it has a very durable construction.

5.The hoses come with a variety of fittings and accessories ensures the water transfer process free of leaking.

6.Temperature range:-5°C~65°C(23~149F)

HDPE Pipe for Agriculture Irrigation System

FAQ Irrigation Tape distance 30cm Good Quality

1.Q:Are you manufactory or trade company?

A:We are the Manufactory specialized in drip irrigation more than 20 years; Our factory have passed IS09000.

2.Q:How can I get the samples?

A:If you need some samples to test, we can make as per your request .You should pay for the transportation freight of samples and our samples cost, while the samples cost can be refundable after you place the order if the amount meets our requirement.

3.Q:How much the transportation freight of samples?

A:The freight depends on the weight and packing size and your area.

4.Q:How long can I expect to get the sample?

A:The samples will be ready for delivery within one week. The samples will be sent via express and arrive in 7-10 days.

5.Q:Can we have our Logo or company name to be printed on your products or package?

A:Sure.Your Logo can be put on your products by Hot Stamping,Printing,Embossing,UV Coating,Silk-screen Printing or Sticker

- Q: How are plastic chicken coops used in backyard poultry farming?

- Plastic chicken coops are commonly used in backyard poultry farming as a convenient and practical housing solution for raising chickens. These coops offer numerous benefits such as being lightweight, easy to clean, and resistant to weather conditions. They provide a secure and comfortable environment for the chickens, protecting them from predators and adverse weather. Plastic coops also have built-in features like ventilation, nesting boxes, and roosting bars, which promote the overall health and well-being of the birds. Overall, plastic chicken coops are a popular choice among backyard poultry farmers due to their durability, functionality, and low maintenance requirements.

- Q: Are agricultural plastic products resistant to pests and insects?

- Yes, agricultural plastic products are generally resistant to pests and insects. The use of durable and high-quality plastics in agricultural applications helps to prevent damage caused by pests and insects, ensuring the protection of crops and increasing overall productivity.

- Q: Can you get cancer if thr plastic like gets into the water?

- The only thing I have heard is that you shouldn't freeze bottled water b/c when it freezes, it releases a chemical from the plastic that can cause cancer.

- Q: Can nursery trays be used for starting fruit tree cuttings?

- Yes, nursery trays can be used for starting fruit tree cuttings. They provide a suitable environment for rooting and initial growth of the cuttings, allowing them to develop strong root systems before transplanting into larger containers or outdoors.

- Q: What are some ground cover options for areas with high salinity?

- Some ground cover options for areas with high salinity include saltbush, sea lavender, seashore paspalum, and alkali grass. These plants have adapted to tolerate and even thrive in salty conditions, making them suitable choices for such areas.

- Q: How are plastic water tanks used in agriculture?

- Plastic water tanks are commonly used in agriculture to store and distribute water for various purposes such as irrigation, livestock watering, and crop spraying. These tanks provide a cost-effective and convenient solution for water storage on farms, allowing farmers to efficiently manage their water supply and ensure proper hydration for their crops and animals.

- Q: is there is any graph which shows phase transformation of plastic after heating then cooling.

- There isn't a phase transformation in plastic like there is in metals. When you heat treat plastic you are just annealing it. In other words the polymer chains are stretched and frozen during the molding process (or any process that melts and solidifies the material) and this creates stresses that when a chemical attack happens the plastic with fracture. When you anneal plastic your allowing stretched polymers to relax. Sometimes this will also cause your perfect part that is under great stress to become warped in its relaxed state. This can be resolved using fixtures when annealing the plastic. To anneal a plastic you need to take the plastic to about 20F below the ASTM D648 @ 66PSI and hold it there for approximately 1/2 hour at that temp. This is difficult if the plastic is very thick (4 blocks of plastic and you want to machine it.) If plasticis not annealed it is similar to having a 1 ton chain with a 1990 lbs hanging on the end of it. All you need is a small force added or a stress concentrator such as oxidation reaction to attach it and the thing will snap in front of you and you can hear and watch it happen. To view the stresses in plastic you can mold the plastic out of a clear polymer and then using 2 polarized sheets and a backlight the stress in the plastic will bend the light and you will see the coloration. These iso bars of color show the location of the stresses (which are typically at corners, gates and at the knit lines. people.rit.edu/andpph/text-polari...

- Q: How are plastic poultry crates beneficial in transportation of poultry?

- Plastic poultry crates are beneficial in the transportation of poultry for several reasons. Firstly, they provide a secure and comfortable space for poultry during transit, ensuring their well-being and minimizing stress. Secondly, the crates are lightweight yet durable, making them easy to handle and reducing the risk of injury to both the birds and the handlers. Additionally, the crates are designed with proper ventilation, allowing for adequate airflow and preventing overheating. They are also stackable, optimizing space and facilitating efficient loading and unloading processes. Overall, plastic poultry crates offer a practical and safe solution for transporting poultry, promoting their welfare and maintaining product quality.

- Q: How do ground cover plants help prevent erosion?

- Ground cover plants help prevent erosion in several ways. Firstly, their roots bind the soil together, creating a dense network that holds the soil in place, preventing it from being washed away by rain or wind. Additionally, ground cover plants act as a barrier, breaking the impact of rainfall and reducing the force that would otherwise directly hit the soil surface. They also help to absorb and retain water, reducing surface runoff and allowing the water to infiltrate into the soil, which further prevents erosion. Overall, the presence of ground cover plants helps to stabilize the soil and protect it from erosion caused by natural elements.

- Q: What types of plastic materials are used in making irrigation channels?

- There are various types of plastic materials used in making irrigation channels, including high-density polyethylene (HDPE), polyvinyl chloride (PVC), and polypropylene (PP). These plastics offer durability, resistance to corrosion, and flexibility, making them suitable for constructing efficient and long-lasting irrigation channels.

Send your message to us

HDPE Pipe for Agriculture Irrigation System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 1999999 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords