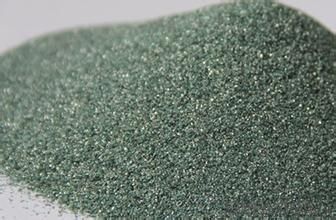

Raw Materials for Refractory:Green Silicon Carbide 3000# for Solar Energy, Abrasive

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Green SiC

1.professional manufacturer

2.hot sale overseas

3.high purity of SiC

Product Description

1.Description:

Green silicon carbide is produced in the same way as Black silicon Carbide except for some differences in raw material. Its crystallization has higher purity and hardness. Green silicon Carbide is suitable for processing hard alloy, metallic and non-metallic materials with hard and brittle feature such as copper, brass, aluminum, magnesium, jewel, optical glass, ceramics, etc.

2. Advantages

a. Large melting furnace, longer melting time, lead to more crystallization, bigger crystalls, higher purity and less impurities.

b. Beckman coulter particle size distribution instrument.

c. Laboratory is registrated at the government Import and Export Inspection Bureau.

3.Chemical Analysis

Purpose | Specification | Chemical Composition(%) | Magnetic material content(%)max | |||

Abrasives grade | SICmin | F.Cmax | Fe2O3max | |||

grain | 12-80 | 99 | 0.20 | 0.2 | 0.0180 | |

90-150 | 98.5 | 0.25 | 0.5 | 0.0150 | ||

180-220 | 97.5 | 0.25 | 0.7 | 0.0120 | ||

micropowder | 240-4000 | 96 | 0.30 | 0.8 | — | |

4.Specification

color | green |

Hardness(mohs) | 9.15 |

Melting point(°C) | 2250 |

Maximum service temperature(°C) | 1900 |

Ture density(g/cm3) | 3.9 |

Packaging & Shipping

1.25kg woven bag,40 woven bags/jumbo bag.

2.25kg woven bag,40 woven bags/pallet

3.25kg paper bag,40 paper bags/pallet

4.25kg paper bag,40 paper bags/paper box

Our Services

Silicon carbide powder is silicon carbide raw block after crushed by Raymond mill, jet mill, ball mill, plastic machine grinding after the formation of the 100 um to fine silicon carbide products.

It Mainly used in refractory products manufacturing, and foam reaction sintering ceramic industry, ceramic, solar wafers cutting, crystal crystal cutting grinding, original car engine manufacturing, special coatings industry, rubber plastics modification, desulfurization, extensive fields such as power supply, environmental protection industry.

The European standard (FEPA):

F240#,F280#,F320#,F400#,F500#,F600#,F800#,F1000#,F1200#,F1500#,F1800#

The Japanese standard (JIS):

#240,#280,#320,#360,#400,#500,#600,#700,#800,#1000,#1200,#1500,#2000,#2500,#3000,

#4000,#6000,#8000.

Green Silicon carbide grit sand :

- Q: Does anyone know the characteristics of refractory for glass kiln?

- Quartzitic sandstone. Also known as quartzitic sandstone or white gravel. Which is a kind of natural refractory and quartz sandstone bonded by the kaolinite. Who appearance is better to be steel-grey, dense and hard, free of impurities and stripes. Its main crystalline phase is mainly quartz and kaolinite. Which has obvious stratified structure and anisotropism. The refractoriness fluctuation is between 1650~1730 ℃. The expansibility of quartzitic sandstone is different from that of silica?brick, who has maximum coefficient of thermal expansion under temperatures of 700 ~ 800 ℃, and it is most likely to burst at this time. The load softening temperature and the compression strength of calcined quartzitic sandstone have been improved significantly, with small residual expansion, stable volume, better thermal shock resistance, so it is generally to use calcinated quartzitic sandstone as refractories. which has been widely used as sidewall blocks on the small and medium sized furnaces.

- Q: What brands are the best in the A-level refractory materials?

- These brands are good.

- Q: How is the grading of the level A new material fire insulation material?

- The standard to distinguish level A and level B is the different fireproofing coefficient. The level A is non-combustible. The level B is divided into B1, B2 and B3. B1 is flame retardant, B2 combustible and B3 flammable. The level A is commonly phenolic aldehyde, rock wool, thermal?mortar, foam ceramics, foam glass and foam concrete on the current market. Among the advantages of level A materials, the biggest one is foam concrete currently, also known as foam cement.

- Q: What is molten silicon? What refractoriness do refractories made by it have? What properties of using does it have?

- Molten silicon can be called quartz glass, which shows an amorphous silicon state. It is a liquid fusion at above 1723 degree and is an ultra-cooling state at low temperatures. It is not generated in refractories, but generated in the matrix, showing liquid state at a high temperature capable of buffering the stress with somewhat binding properties. If quartz glass is used as refractory, its function are melrly these ones. (These are what I konw for reference only.)

- Q: What a blast furnace refractories generally?

- Usually metal anchorage plus wear-resistant refractory spray paint. at the middle part we use high alumina bricks, corundum bricks. high duty refractory is important in improving bosh furnace lining.

- Q: Does the refractory material used in steelmaking all refer to refractory brick?

- It includes not only refractory brick but also unshaped refractory; while the foaming?agent, ladle filler sand and deoxidizer are not refractory materials but ferrous metallurgy auxiliary materials.

- Q: what's the requirements of refractory for forge furnace?

- High temperature resistance, good slag resistance.

- Q: What are the best refractory materials in 2,400 Celsius degree?

- and carbon fiber or nanomaterials.

- Q: What is the mechanism of the errosion of the iron to the refractories?

- For example, the effect of the iron oxide: Mo corundum given temperature Fe2O3 solid solubility limit of the solid solution formed of corundum stone high solubility than the solid solution Mo Mo corundum lattice shape so Fe2O3Al2O3-SiO2-based material starts melting temperature of the system or the content of Al2O3 and Al2O3 / SiO2 ratio off Al2O3 / SiO2 & lt; 2.55 starting melting temperature of 1380 ℃ when Al2O3 / SiO2 & gt; 2.55 start melting temperature is increased 1460 ℃ and with its Al2O3 content increased gradually to increase the original atmosphere Fe2O3 original FeO off the solvent into the glass phase and the system starts melting temperature drops do not fall to 1240 ℃ 1380 ℃. Lower the melting point, increase the erosion, and reduce the life span.

Send your message to us

Raw Materials for Refractory:Green Silicon Carbide 3000# for Solar Energy, Abrasive

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords