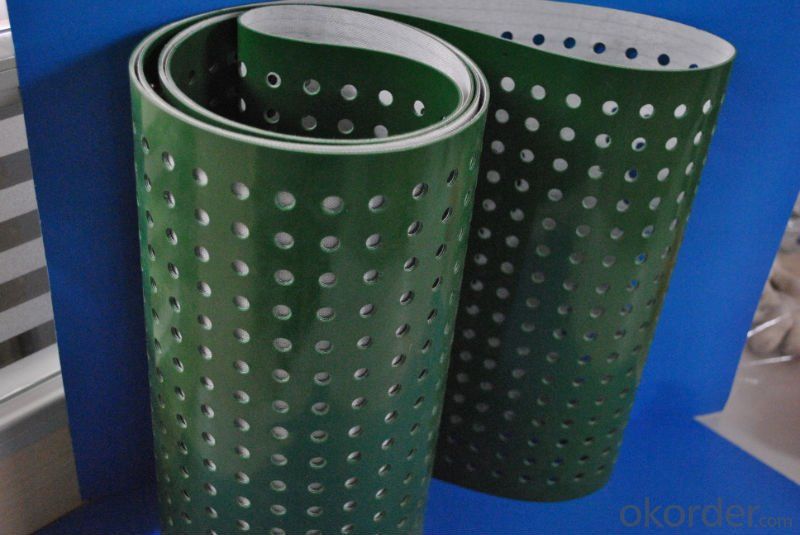

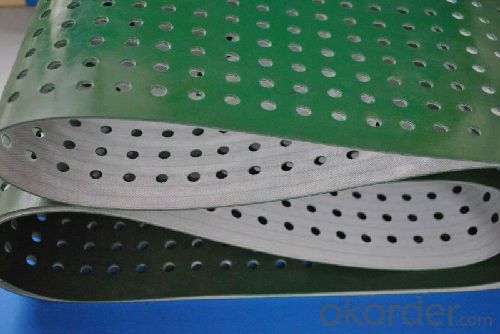

Green PVC Conveyor Belt with Punching Hole

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Conveyor Belt with Punching Hole

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

Appearance:

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Application:

PVC: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines belt.

PU: Most applicable to the food industry and other industries .

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

1.High tensile strength, well circumnutate properties, light, thin, pliable but strong, oil resistant,non-toxicity,hygiene,easy clear.

2. Abrasion resistance,anti physical aging.

3. Acid/alkali resistant,cutting resistant,small turning radius.

4. It can be added V-type conducting bar underside and conducting bar or baffle on the surface.

5. Colors:white and green,etc.

6.Different thickness and width.

7.Appearance:high gross surface,matte,mainly used in food industry.

PVC/PU CONVEYOR BELT APPLICATION AREAS

Office automation equipments

Medical equipment

Packaging machinery

Swimming pool cleaning robots

Plotters

Money changers

Optical instruments

Robotic arms

Electric appliances

Vacuum systems

Vending machines

Food machinery

Textile machinery

DIY equipments

Product Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products based on your requirements.It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1)All raw material we used are environmental-friendly;

2)Skilful workers care every details in handling the producing and packing processes;

3)Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance payment before shipment.

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What are the hazards of plastic oiler

- Fire easily, easily bitten by rats, cold oil solidification also fell out.

- Q: Can olive nets be used in olive groves with limited access for machinery?

- Yes, olive nets can be used in olive groves with limited access for machinery. Olive nets are lightweight and easy to install manually, making them suitable for groves where machinery cannot easily navigate. These nets can be manually spread across the trees to collect falling olives during harvest, providing an efficient solution for groves with limited machinery access.

- Q: Do olive nets require any maintenance?

- Yes, olive nets require regular maintenance to ensure their effectiveness. They need to be regularly inspected for any damage or holes that may allow olives to escape. Additionally, they should be cleaned and stored properly after each use to prevent damage and prolong their lifespan.

- Q: Can olive nets be used to improve fruit quality?

- Yes, olive nets can be used to improve fruit quality. Olive nets help protect the fruit from damage caused by insects, pests, and birds. They also provide shade, which can prevent sunburn and maintain a more optimal temperature for fruit development. Additionally, olive nets reduce the risk of contamination from dust and debris, resulting in cleaner and higher quality fruit.

- Q: Do olive nets require any special installation techniques for densely planted groves?

- Yes, olive nets may require special installation techniques for densely planted groves. In densely planted groves, the proximity of trees can make it challenging to spread the nets evenly and ensure effective coverage. Special techniques such as using longer poles or enlisting additional help may be necessary to properly install olive nets in densely planted groves.

- Q: How do olive nets prevent olives from being damaged by heavy rain?

- Olive nets prevent olives from being damaged by heavy rain by providing a protective barrier that shields the olives from direct contact with the raindrops. The nets act as a shield, reducing the impact of the rain and preventing it from hitting the olives directly, thus minimizing the potential for damage, rot, or spoilage.

- Q: What is the lifespan of an olive net?

- The lifespan of an olive net can vary depending on various factors such as the quality of the net, the frequency of use, and the overall care and maintenance. However, on average, a well-maintained olive net can last for several years, typically ranging from 3 to 5 years.

- Q: Can olive nets be used to promote organic certification?

- Yes, olive nets can be used to promote organic certification. Olive nets are commonly used in organic farming practices to protect the olives from pests and ensure they are not contaminated with synthetic chemicals. By using olive nets, farmers can demonstrate their commitment to organic farming methods, which can help in obtaining organic certification. Additionally, the use of olive nets can help maintain the quality and integrity of the olives, which is essential for meeting the standards required for organic certification.

- Q: Do olive nets require any special training for installation?

- No, olive nets do not require any special training for installation. They are simple to set up and can be done by anyone following the instructions provided.

- Q: Can olive nets be used in olive groves with limited access to sunlight?

- Yes, olive nets can be used in olive groves with limited access to sunlight. Olive nets are primarily used to protect the olives from birds and other pests, and they do not rely on sunlight for their functionality. However, it is important to ensure that the olive trees still receive sufficient sunlight for their growth and productivity even with the presence of the nets.

Send your message to us

Green PVC Conveyor Belt with Punching Hole

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords