GRE Pipe for Oil Exploration and Transportation

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Meters m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of GRE Pipes for Oil Exploration and Transportation

Lightweight and easy to handle and install, GRE pipes have a smooth internal surface that reduces friction and enables a high pipe flow capacity. The low thermal conductivity of GRE pipes relative to steel (only one percent of steel values) minimises the cost of insulation and heat loss. Another major benefit of GRE pipes is that, once they are installed, they are virtually maintenance-free.

GRE pipes are well suited for environments where corrosion resistance is required at a reasonable price.

Main uses include petrochemical process lines, oil and gas systems, fire-fighting systems, offshore and onshore systems, and ship and marine applications.

GRE pipes are available in diameters ranging from DN 25 to DN 1,000 mm.

Advantage of GRE Pipes for Oil Exploration and Transportation

Excellent chemical resistance property

Able to withstand high pressur and high termperature

Higher transportation efficiency

Ligh-weight easy to install

Designable electrical property

Lower abrasion coefficient

Able to connect with steel pipe

Smoothly inner wall, no scaling, no waxing, not prone to clogged

Longer service life that is 4 to 5 times compare to steel pipe(about 20 years)

Low maintenance cost

Application of GRE Pipes for Oil Exploration and Transportation

Injection and delivery pipeline

Crude oil

Potable water

Brine transport pipeline

Oilfield sewage, chemical sewage and wastewater process pipeline

Fire water pipeline

Storage tank connector

Polymer solution transmission pipeline

Petrochemical process pipeline

Geothermal pipes

Slotted liner and sieve vessels

Natural gas

CO2 or H2S

CO2 or H2S gathering and transport lines

Specification of GRE Pipes for Oil Exploration and Transportation

Anhydride GRE pipe | |||||||||

Diameter | Pressure | ID | OD | Threading | Wall Thickness | Weight | Min. Radius | Length/pc | |

mm | (in) | (Mpa) | (mm) | (mm) | (in) | (mm) | (Kg/pc) | (m) | (m) |

DN40 | 1 1/2 | 7 | 38.2 | 41.8 | 1.9 | 1.78 | 6.2 | 30 | 9.14 |

8.5 | 38.2 | 41.8 | 1.78 | 6.5 | 30 | ||||

10 | 38.2 | 42.3 | 2.04 | 7.5 | 30 | ||||

12 | 38.2 | 43.2 | 2.48 | 7.8 | 30 | ||||

14 | 38.2 | 44 | 2.92 | 8 | 32 | ||||

16 | 38.2 | 45 | 3.38 | 9.8 | 32 | ||||

18 | 38.2 | 45.9 | 3.86 | 10 | 34 | ||||

20 | 38.2 | 46.9 | 4.34 | 11.3 | 34 | ||||

22 | 38.2 | 47.9 | 4.85 | 13 | 36 | ||||

25 | 38.2 | 49.5 | 5.63 | 14.6 | 38 | ||||

DN50 | 2 | 5.5 | 50.6 | 54.1 | 2 3/8 | 1.78 | 8.9 | 40 | 9.14 |

7 | 50.6 | 54.3 | 1.86 | 9.2 | 40 | ||||

8.5 | 50.6 | 55.1 | 2.27 | 10.7 | 42 | ||||

10 | 50.6 | 55.9 | 2.7 | 11 | 42 | ||||

12 | 47.9 | 54.1 | 3.1 | 11.6 | 42 | ||||

14 | 47.9 | 55.2 | 3.67 | 13.3 | 42 | ||||

16 | 47.9 | 56.4 | 4.24 | 15.2 | 44 | ||||

18 | 47.9 | 57.6 | 4.84 | 17.1 | 44 | ||||

20 | 47.9 | 58.8 | 5.45 | 17.4 | 44 | ||||

22 | 47.9 | 60.1 | 6.08 | 19.6 | 44 | ||||

25 | 47.9 | 62 | 7.06 | 23.4 | 46 | ||||

DN65 | 2 1/2 | 5.5 | 62.4 | 65.9 | 2 7/8 | 1.78 | 11.6 | 48 | 9.14 |

7 | 62.4 | 67 | 2.29 | 13.7 | 48 | ||||

8.5 | 62.4 | 68 | 2.8 | 14 | 50 | ||||

10 | 62.4 | 69 | 3.33 | 14.3 | 50 | ||||

12 | 56.5 | 63.8 | 3.66 | 17.9 | 50 | ||||

14 | 56.5 | 65.1 | 4.32 | 18.2 | 50 | ||||

16 | 56.5 | 66.5 | 5.01 | 20.9 | 52 | ||||

18 | 56.5 | 67.9 | 5.7 | 24.3 | 52 | ||||

20 | 56.5 | 69.3 | 6.42 | 27.1 | 54 | ||||

22 | 56.5 | 70.8 | 7.17 | 29.5 | 54 | ||||

25T&C | 56.5 | 73.1 | 8.32 | 33 | 56 | 8.9 | |||

DN80 | 3 | 3.5 | 75.9 | 79.4 | 3 1/2 | 1.78 | 14.1 | 60 | 9.14 |

5.5 | 75.9 | 80.2 | 2.17 | 14.7 | 60 | ||||

7 | 75.9 | 81.4 | 2.79 | 16.9 | 60 | ||||

8.5 | 75.9 | 82.7 | 3.41 | 19.8 | 60 | ||||

10 | 69.3 | 76.7 | 3.7 | 20.7 | 60 | ||||

12 | 69.3 | 78.3 | 4.49 | 23.5 | 62 | ||||

14 | 69.3 | 79.9 | 5.3 | 26.1 | 62 | ||||

16 | 69.3 | 81.6 | 6.14 | 28.5 | 62 | ||||

18 | 69.3 | 83.3 | 7 | 31.5 | 64 | ||||

20 | 69.3 | 85.1 | 7.88 | 34 | 64 | ||||

22 | 69.3 | 86.9 | 8.79 | 39.9 | 64 | ||||

25T&C | 69.3 | 89.7 | 10.21 | 45.9 | 66 | 8.9 | |||

DN100 | 4 | 3.5 | 100.9 | 104.5 | 4 1/2 | 1.82 | 21.3 | 74 | 9.14 |

5.5 | 100.9 | 106.7 | 2.89 | 24.7 | 74 | ||||

7 | 100.9 | 108.3 | 3.7 | 28.7 | 74 | ||||

8.5 | 100.9 | 110 | 4.54 | 32.7 | 74 | ||||

10 | 100.9 | 111.7 | 5.38 | 36.7 | 74 | ||||

12 | 85.1 | 96.1 | 5.51 | 38.4 | 76 | ||||

14 | 85.1 | 98.1 | 6.51 | 42.3 | 76 | ||||

16 | 85.1 | 100.2 | 7.54 | 46 | 76 | ||||

18T&C | 85.1 | 102.3 | 8.59 | 55.9 | 76 | 8.8 | |||

20T&C | 85.1 | 104.5 | 9.68 | 65.2 | 76 | ||||

22T&C | 85.1 | 106.7 | 10.79 | 71.2 | 80 | ||||

DN150 | 6 | 3.5 | 159.5 | 165.2 | 7 | 2.87 | 45.6 | 110 | 9.14 |

5.5 | 159.5 | 168.6 | 4.56 | 51.5 | 110 | ||||

7 | 159.5 | 171.2 | 5.86 | 63 | 110 | ||||

8.5 | 159.5 | 173.8 | 7.17 | 73.3 | 112 | ||||

10 | 137.9 | 152.6 | 7.36 | 81.2 | 112 | ||||

12T&C | 137.9 | 155.8 | 8.94 | 96.4 | 112 | 8.8 | |||

14T&C | 137.9 | 159 | 10.55 | 114.7 | 112 | ||||

16T&C | 137.9 | 162.3 | 12.22 | 124.7 | 116 | ||||

DN200 | 8 | 3.5 | 193.8 | 200.8 | 8 5/8 | 3.49 | 77.3 | 130 | 8.6 |

5.5 | 193.8 | 204.9 | 5.54 | 90.7 | 130 | ||||

7 | 193.8 | 208 | 7.11 | 104.7 | 130 | ||||

8.5 | 193.8 | 211.2 | 8.71 | 127.4 | 135 | ||||

10T&C | 193.8 | 214.5 | 9 5/8 | 10.34 | 173.5 | 135 | 8.2 | ||

12T&C | 193.8 | 218.9 | 12.56 | 184.6 | 140 | ||||

14T&C | 193.8 | 223.5 | 14.83 | 198.5 | 140 | ||||

FAQ:

1, Connection of the GRE Pipes:

API screw thread seal with aquaseal connection of 8 round or 10 round;

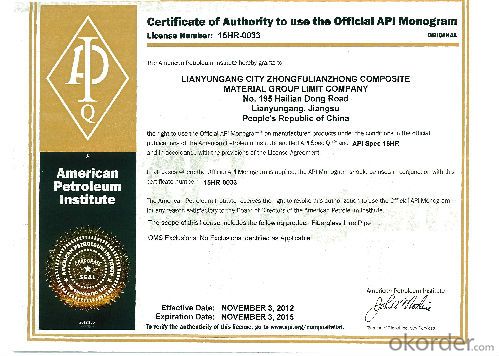

2, Standard of the GRE Pipes?

API Spec 15HR

3, Fittings supplied?

All of the standard GRE fittings are matched well with the original pipes. Most of the fittings are produced by filament winding process.all fittings should be ordered as per thread specification and design pressure.

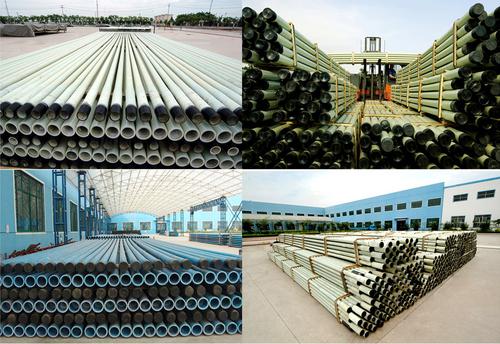

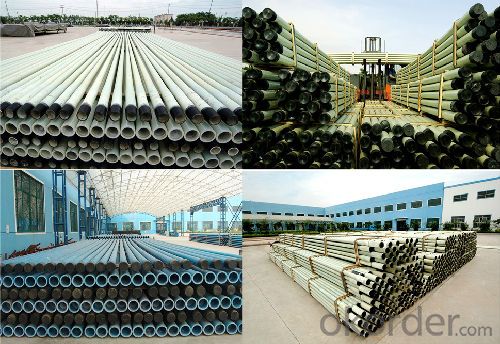

Photos:

- Q: What are FRP pipes made of?

- Light weightThe weight of the pipe is only 1/4 of the same size and the same length as the ductile iron pipe, and 1/10 of the cement pipe. The transportation is easy to handle and easy to install.

- Q: Winding method of glass fibre reinforced plastic pipeline anticorrosive glass fiber cloth

- 1) FRP reinforcement, length of rectangular duct is greater than 900mm, and the pipe length is more than 1250mm, should be strengthened. The reinforcement shall be made of bulk material (fiber reinforced plastic) and reinforced plate at the maximum stress, so as to increase the modulus of the section and increase the overall strength of the tube. FRP reinforcement can also be in the wind pipe production is completed, the treated metal or other corrosion resistant material for reinforcement, reinforcement and FRP as a whole, and with the same pipeline body cementitious material sealing gap2) hobas pipe surface thickness of the slurry to flatten the glass fiber mesh cloth texture is appropriate (see:). No dense air holes and grout leaks are allowed on the wall of the pipe to avoid the stress concentration under the bending tensile stress (positive air pressure) and the bending compressive stress (negative wind pressure).3) FRP pipe and flange corner should transition arc, transition radius to wall thickness of 0.8 ~ 1.2 times, improve the bearing capacity and the cantilever flange to avoid stress concentration. Fiberglass mesh shall be extended to the duct at the flange of the duct.

- Q: Raw material and mix ratio of inorganic glass fibre reinforced plastic wind pipe

- In order to improve the quality of glass.Advanced technology may be used.The ratio seems to be 1 to 0.001. Pretty much within this range.

- Q: What qualifications do FRP pipes need to export to Australia?

- Large enterprises have an international quality system that can be consulted by local customs clearance agents. The company must be combined with local regulations to be taken care of

- Q: What's the difference between glass fiber reinforced plastic pipe and glass fiber reinforced sand pipe? What kind of material is good?

- There are two main functions of glass fiber reinforced plastic sand adding, one is to improve the rigidity, the other is to reduce the cost. These two aspects just agree with the municipal, the dosage is large, the pressure is low, and the underground and maintenance are few.

- Q: How is FRP ventilation pipe made?

- Solidification strippingThe coated FRP pipe can be released after a period of constant pressure to a certain strength. When the mold is released, the pre - prepared ejection support points shall be removed to separate the mold from the molded air pipe and then to exit the mold. Finally, remove the glass paper on the inside and outside surface. Air duct after stripping. Excess parts or burrs can be polished by hand cutting machine or sand grinder.

- Q: What epoxy resin is used for anticorrosion of pipeline glass fiber reinforced plastics?

- 3PE has been anti-corrosion principle, there is no need for anti-corrosion, but now the domestic situation. Directional drilling pipe cannot be detected and repaired, the anticorrosion layer cannot have serious damage to the pipeline, long-term safety operation, it should be required for coating directional drilling: scratch resistance, abrasion resistance, impact resistance, high hardness, strong adhesion and pipeline, corrosion resistance, water resistance have a good soak, matching and cathodic protection system.

- Q: The role of glass fiber reinforced plastic cooling towers

- Is specializing in the production of glass steel cooling tower, cooling tower, cooling tower, commonly known as cooling tower, glass tower, tower, main square, round, crossflow and counterflow, no filler spray cooling tower series.

- Q: Excuse me, what standard does the glass fiber that check mechanical and electrical use accord with GB?

- It is a resin based glass fiber weight layer wound on the mandrel rotating on according to process requirements, and distance evenly between the fibers as Kamiishi Eisa in the sand layer.

- Q: A basic overview of FRP pipes

- FRP pipes are used in petroleum, chemical and drainage industries. Glass fiber reinforced plastic pipeline production in China has developed rapidly, and the quantity has been increasing year by year, and the scope of application and departments are becoming wider and wider.

Send your message to us

GRE Pipe for Oil Exploration and Transportation

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Meters m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords