Graphite Electrode Industry Standard Dia.40-600mm or 1.6"-24" Graphite Electrodes

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to 700mm. Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

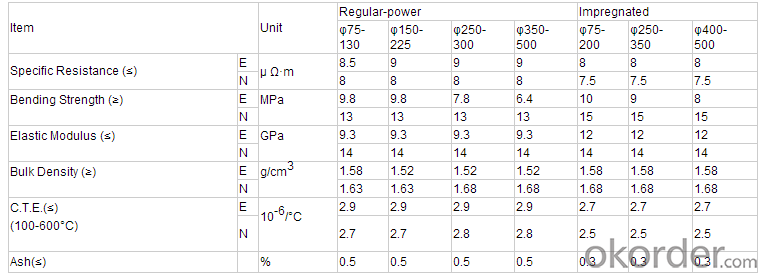

Graphite Electrodes Specifications

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, RPI, HP, SHP, UHP

All graphite electrodes are offered with tapered nipples, i.e. 3 or 4 threads per inch, and meet the internationally accepted tolerances as per NEMA CG 1/ IEC 60239 / JIS R7201 standards.

Technical data:

Note: The consumption of Electric Arc Furnace(EAF) is about 3-5kg per ton steel. The Ladle Furnace(LF) is about 1kg per ton steel. The converter with Ladle Furnace(LF) is about 0.5kg per ton steel. All the information is for your reference. There are many factors can influence the consumption, such as the kinds of steel, conduction time, process production and so on. So if you have any question, please don’t hesitate to contact us.

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Classification, uses and manufacturers of graphite electrodes

- Graphite as electrode(1) the processing speed is faster: normally, the mechanical processing speed of graphite can be 2~5 times faster than copper, while the discharge processing speed is 2~3 times faster than copper;More material is not easily deformed: obvious advantages in the processing of thin electrodes; copper softening point at about 1000 degrees, easily deformed by heat; graphite sublimation temperature is 3650 degrees; the thermal expansion coefficient of copper is only 1/30.(2) lighter weight: the density of graphite is only 1/5 of copper. When large electrode is used for discharge machining, it can effectively reduce the burden of machine tools (EDM). It is more suitable for large-scale die applications.

- Q: Where is the graphite electrode scrap?

- Atoms, ions, and electrons collide with each other in strong oscillatory motion to produce more electrons and ions.

- Q: What is the graphite furnace electrode with a diameter of 400?

- With the development of EAF steelmaking technology, the steel-making technology is developing towards large scale and ultra high power. The graphite electrode is mainly made of large size graphite electrode and ultra high power graphite electrode.

- Q: What are the structures of pyrolytic graphite electrodes? What are their properties and applications? We hope that some details will not be found

- The high purity graphite component is put into the furnace, and nitrogen and methane are produced under vacuum high temperature. Then graphite is shown to produce 10% coating.

- Q: Synthesis techniques of carbon nanotubes

- The synthesis techniques of carbon nanotubes are mainly arc method, laser ablation (Zheng Fa) method, catalytic cracking or catalytic chemical vapor deposition (CCVD), and directional control growth method based on various synthesis techniques.

- Q: What kind of asphalt is better for natural graphite coating?

- Special graphite mainly to high quality petroleum coke as raw material, coal tar or synthetic resin as binder, the raw material preparation, mixing, kneading, pressing, crushing, mixing, molding, roasting, soaking, repeatedly repeated purification and graphitization, and made the processing machine. It is generally used in the aerospace, electronics and nuclear industry sectors. It includes pure graphite, high purity, high strength, high density and pyrolytic graphite.

- Q: Electrolytic water solution, two electrodes are graphite electrode, the negative electrode can produce large amounts of hydrogen, the anode does not produce half of oxygen, and only a small amount of it?

- Anodic iron is directly oxidized without oxygen generation

- Q: Are graphite and carbon electrodes the same? What kinds of ore furnaces are used?

- The main components of carbon electrodes are graphite, carbon powder and other impurities which are not converted into graphite. The resistivity is higher than that of graphite electrode. These electrodes are mostly used in electric furnace steelmaking, smelting aluminium oxide and other electric arc furnaces.

- Q: Can Naiduo high temperature graphite

- The reinforced graphite gasket is made of flexible graphite tape or flexible graphite and is molded into ring products of different sizes. Suitable for hot water, high temperature, high pressure steam, heat exchange liquid, nitrogen gas, organic solvent, hydrocarbon, low temperature liquid and other medium. Used in compressors, machines, pumps, valves, chemical instruments, instruments, etc..

- Q: What are the factors that affect the electrode wear rate of machine tools?

- Effect of processing voltage on electrode wear. The processing voltage is the average voltage between the discharge time and the gap. When the voltage is lower than the power supply voltage (voltage) 25%, electrode loss will increase, which is due to the electrode and the workpiece is too close, the discharge column energy is too large, the electrodes generate heat radiation is too strong, at the same time, there are a large number of continuous arc discharge. But the working voltage is too high (partial load processing), bad conditions of thermal effect in the gap, is not conducive to the adsorption of copper electrode of carbon graphite, destroy the covering effect. Similarly, the electrode loss increase, therefore, corresponding to different processing standards should be selected to adjust the discharging gap voltage.

Send your message to us

Graphite Electrode Industry Standard Dia.40-600mm or 1.6"-24" Graphite Electrodes

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords