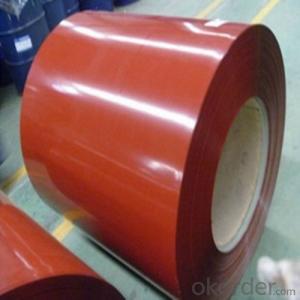

Good Quality Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Steel grade: DX51D,SS grade 33-80 SGCC Q195

Big discount for quantities .

Competitive price directly from our own factory.

cold rolled hot dip galvanized steel coil/

Galvanized steel coils are widely used in the construction industry, as raw material for the production of corrugated panels, fencing products, drywall panel profiles, ventilation systems etc. Recommended for both outside and inside usage, galvanized steel has a high resistance to corrosion in different environments, due to a protective layer of zinc of 100 – 180 grams per square metre.

Hot-dip galvanized steel coils are produced by immersing steel in a zinc bath. An appropriate galvanizing process requires a pretreatment process during which the steel passes through different baths which prepare the surface for zinc coating. In this stage, chemicals are used to clean the surface of the steel. After the chemical treatment, the steel coils pass through a bath of melted zinc at temperatures around 460 ° C. The resulting uniform coating is finished through a process of skin-passing to provide smooth and shiny appearance of the finished product. To store for a longer period, the hot-dip galvanized coils can be delivered with a final oil coating, according to the customer’s demand.

PROFILAND STEEL produces hot-dip galvanized steel coils with very good workability at further cold forming and bending processes.

Technical specification for the hot-dip galvanized produced by PROFILAND STEEL::

• Steel grade: DX51D+Z• Zinc coverage: 30-180 g/sqm on both sides (depending by the requested specification);• Thickness: between 0,2 mm and 1,00 mm;• Width: 600mm,914mm,1000mm, 1220mm and 1250 mm;• Coil weight: 4-6 mt;• Coil ID: 508 mm;• Coil OD: 900-1500 mm ;

Depending on their usage, the hot-dip galvanized coil can be delivered slightly oiled.

- Q: Any details about JinSong Ferritic Stainless Steel?

- JinSong SUS420J2 stainless-metallic/ X30Cr13 has larger intensity, hardness and hardenability than 12Cr13 metallic and 20Cr13 metallic after quenching. It has much less corrosion resistance to dilute nitric acid and vulnerable organic and organic acid than 12Cr13 metallic and 20Cr13 metallic in room temperature. you will get extra strategies on its good website**

- Q: What is the purpose of steel coils?

- The purpose of steel coils is to efficiently store and transport large quantities of steel in a compact and organized manner.

- Q: What are the different methods of slitting steel coils?

- There are several different methods of slitting steel coils, each with its own advantages and limitations. Some of the most common methods include: 1. Rotary Shear Slitting: This method involves using rotating knives to cut the steel coil into narrower strips. It is a versatile and efficient method that allows for high-speed production and precise slitting. Rotary shear slitting is commonly used for thinner gauge materials. 2. Looping Pit Slitting: In this method, the steel coil passes through a looping pit where it is guided and tensioned before being slit. It is suitable for thicker gauge materials and provides good edge quality. Looping pit slitting allows for higher coil speeds and can handle heavier coils. 3. Drag Slitting: This method involves dragging the steel coil over a stationary blade or set of blades to perform the slitting. It is particularly useful for materials that are difficult to slit, such as high-strength steels. Drag slitting provides excellent edge quality and is often used for precision slitting applications. 4. Crush Slitting: Crush slitting involves applying pressure to the steel coil to crush and separate it into narrower strips. It is a cost-effective method suitable for lower gauge materials. However, it may result in slightly rougher edge quality compared to other methods. 5. Laser Slitting: Laser slitting utilizes a focused laser beam to cut through the steel coil. It is a highly precise method that offers excellent edge quality and minimal distortion. Laser slitting is commonly used for high-value and specialty materials. Each method has its own advantages and is suitable for specific applications and material types. The choice of slitting method depends on factors such as material thickness, desired edge quality, production speed requirements, and budget.

- Q: When steel is cast, does it become weaker/more brittle or anything of this nature? what are the side effects of steel casting on the steel itself?How can you correct these?

- It contains too many air bubble spacing and too many impurity that make it easily to be broken apart. Melt it down again with high heat to remove most impurity, after this process,it becomes iron.

- Q: I want to anodize steel using heat. some steel turns gray instead of coloring when I heat it up using a torch.

- Steel doesn't anodize in the sense that aluminum and some other metals do. However, it can be heat-colored. The trick is to clean the surface first (it must be oxide free), then heat gently until the colors appear. These are called temper colors in steel. They are due to a thin adherent layer of oxide that forms and thickens as temperature is increased. They are quite temperature dependent. As the steel is heated, the first color to appear is pale yellow. This will progress through darker yellows, browns, purples, and blues as the temperature rises. Above blue, the oxide becomes the gray/black color you are apparently getting - this is the result of heating too fast and too hot. See the chart at the site below for colors in plain carbon steel. Note that the temperatures are pretty low - It all starts around 400 F and if you go above 600 F the show's all over.

- Q: What are the different methods of laminating steel coils?

- There exist multiple techniques for laminating steel coils, each possessing its own advantages and applications. The prominent techniques encompass hot rolling, cold rolling, and continuous annealing. Hot rolling involves heating the steel above its recrystallization temperature and subsequently passing it through a sequence of rollers to generate thin sheets or coils. This method is frequently employed for the mass production of steel with a uniform thickness and surface finish. Structural applications such as construction and automotive manufacturing commonly utilize hot rolled steel coils. In contrast, cold rolling entails passing the steel coil through a set of rollers at room temperature. This process not only reduces the thickness of the steel but also enhances its surface finish and mechanical properties. Industries requiring high precision and quality, such as appliance manufacturing, electrical equipment, and automotive components, typically employ cold rolled steel coils. Continuous annealing represents an alternative approach to laminating steel coils. It involves heating the steel coil to a specific temperature and gradually cooling it in a controlled environment. This procedure aids in alleviating internal stresses and enhancing the mechanical properties of the steel, such as strength and ductility. Continuous annealing is frequently utilized to produce high-quality steel coils for applications necessitating superior surface finish and formability, like automotive body panels and household appliances. Additional less prevalent methods of laminating steel coils comprise electro-galvanizing and hot-dip galvanizing. Electro-galvanizing encompasses coating the steel with a zinc layer through an electroplating process, while hot-dip galvanizing entails immersing the steel coil in molten zinc. These techniques primarily serve corrosion protection purposes and are commonly employed in the construction industry, particularly for outdoor structures and infrastructure. To summarize, the various techniques for laminating steel coils encompass hot rolling, cold rolling, continuous annealing, electro-galvanizing, and hot-dip galvanizing. Each approach offers distinct advantages and is selected based on the specific requirements of the application.

- Q: How are steel coils used in the production of metal cladding?

- Steel coils are used in the production of metal cladding as they are rolled into flat sheets and then formed into various shapes and profiles. These coils provide the raw material for manufacturing metal cladding panels, which are widely used in construction for their durability, weather resistance, and aesthetic appeal.

- Q: Which one would be stronger? And should damascus steel be tempered?Thank You

- Damascus steel is in history books only,no body knows its composition.THey just named a modern steel as Damascus steel

- Q: How are steel coils used in the production of metal signage?

- The production of metal signage relies heavily on steel coils, which are indispensable components. These coils are typically crafted from top-notch steel and are available in various dimensions and widths. By utilizing steel coils, manufacturers can achieve efficient and cost-effective production methods. To commence the process, the steel coils are unraveled and fed into a machine known as a roll former or a metal press. This machine molds the steel into the desired shape and design for the signage. The malleability and moldability of the coils make them perfect for creating intricate and personalized signage designs. Once the steel has been shaped, it can undergo several treatments to enhance its appearance and durability. For instance, a layer of paint or powder coating can be applied to protect the steel from corrosion and provide an aesthetically pleasing finish. This protective coating can also be tailored to meet specific branding or design requirements. After the steel has been shaped and coated, it can undergo further processing to add features such as embossing or perforations. These additional details can amplify the overall visual appeal of the metal signage and make it truly stand out. Moreover, steel coils possess exceptional structural integrity, ensuring that the metal signage remains robust and long-lasting, even in harsh environmental conditions. This durability is particularly crucial for outdoor signage that needs to endure exposure to weather elements such as rain, wind, and sunlight. In conclusion, steel coils are indispensable in the production of metal signage. Their versatility, durability, and ease of manipulation make them the ideal material for creating customized designs. Whether the signage is intended for indoor or outdoor use, steel coils provide the necessary strength and aesthetic appeal needed for high-quality metal signage.

- Q: Are Steel buildings Fire Resistant, just want to know as I am going to owe it . Suggestions required…………..

- Rather depends on the construction method. I've seen a lot of buildings with a steel exterior referred to as 'steel construction', when in fact they had timber framing - not steel. Recently, in my neck of the woods, we had an ice/snow storm, and many timber framed steel buildings collapsed, because of the weight on the roof. A case of not enough pitch on the roof, and not strong enough construction. The fact that there were many that collapsed, tells me the standards for this region are not high enough, hehehe. How a building is finished inside will also affect how fire resistant it is, let alone, the many other factors that come into play, such as wiring, gas lines, and what is actually done (or contained) inside the building. All details not provided. Better Questions Yield Better Answers. Good Luck

Send your message to us

Good Quality Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords