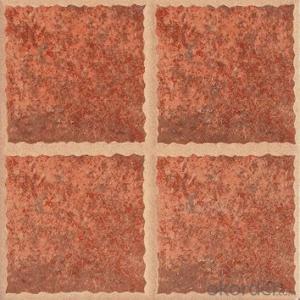

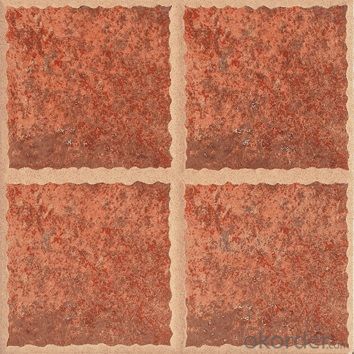

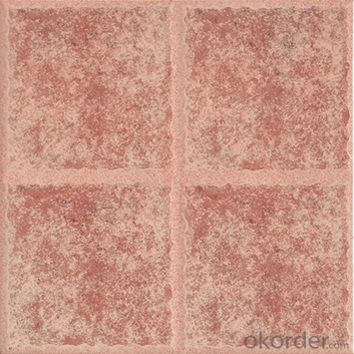

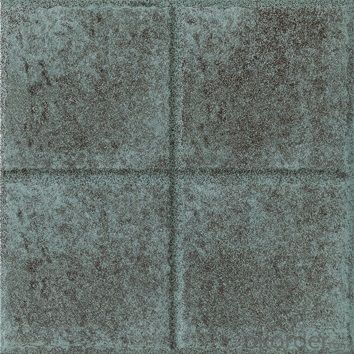

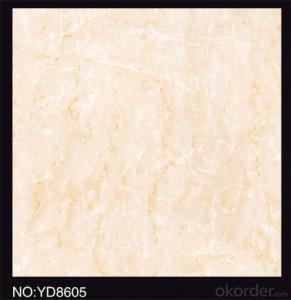

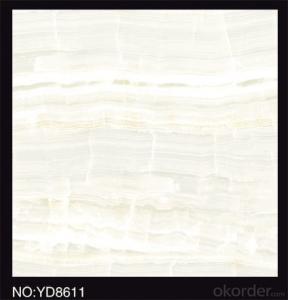

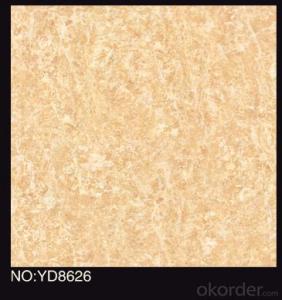

Glazed Floor Tile 300*300mm Item No. CMAX3A340

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1683 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Brief Introduction

Glazed Floor Tile 300*300mm, CMAX3A340 is one of the popular models of 300*300 mm glazed floor tile, which is wildly used for floor of kitchen and bathroom as well as balcony and bedroom. These tiles could create an antique feel of classic European life, just like living in the old times of nature and pastoral life.

Product Features

Glazed Floor Tile

Only Grade AAA available

Strict control on glazing, water absorption rate as well as color shade and straigtness

Competitive price

Standard export packing: Pater Carton+ Wooden Pallet

Fast delivery

OEM service could be offered

Marketing support on samples, catalogues as well as carton designing

Professional sales team for product, document and schedule of importing and exporting.

Product Specification

Tile Type: Dry-Pressed Tile, Silk Printing Glazed Surface

Quality standard: GB/T4100-2006, ISO13006, ISO9001

Water Absorption Rate: 3% -- 6%

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.15%

Edge Straightness: ±0.15%

Packing Information (For 27.5 Tons heavy 20’Fcl)

11pcs/Ctn, 18.5kg/Ctn,1472Ctns/20’Fcl, 1457.28m2/20’Fcl

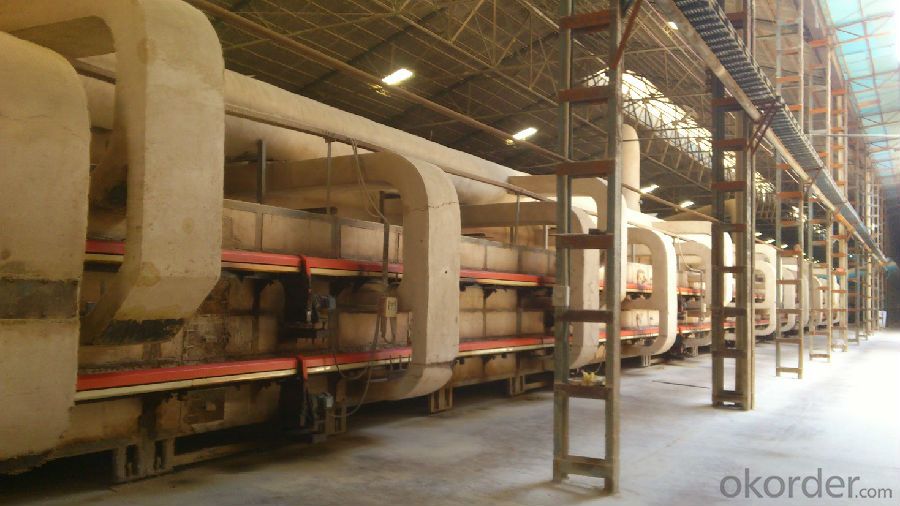

Production Line & Package

FAQ

1. For the delivery term, could you go with CFR our port?

—— Yes, of course. We have very good relationship with those big shipping company, such as China Shipping, MSC, HPL etc.

2. What is the MOQ for this tile?

—— Normally the MOQ is one 20’ container. For some special model, if its production is not arranged frequently, the MOQ is 5 containers.

- Q: My kitchen has a white ceramic tile floor. It never looks clean, every speck of dirt shows. Because we live in a slab home, the tiles are glued right to the concrete. I hate to think how much work it would be to remove them. I could tile over - but it would make the kitchen floor higher than the surrounding rooms. Is there any suitable product for changing the color of the tile in such a high traffic area?

- Have you considered a tile cleaning service? Replacing would take about a week. I would not tile over existing tile. There are products that can be applied over your existing tile that look exactly like a tile floor, but the process costs about the same and takes just as long as re-tiling. Also the person doing it really has to know what they are doing or the job can look terrible. Holmes on Holmes just did a show on the process and it appeared a bit complicated and does not allow much room for error. I'd either get them professionally cleaned or removed and re-tile.

- Q: I have 12x12 field tile and a strip of accent that‘s about 2 high. Everything I‘ve read says that you want to have the accent at eye level, which makes sense to me. Judging for myself, it LOOKS best at eye level. If I place it at eye level, I wind up with a full 12x12 tile above it, or at least, a 12 space above it. So going down to the tub, I would have a 2 1/2 cut tile at the bottom, right above the tub.Everything I have read also says that you want to have the cut tiles at the top and bottom symmetrical.

- Provided the tub is fairly level, start a full tile at the bottom and work up. Tile will look fine at a 5 or six foot level ( I prefer 5 ft.) Not every one has the same eye level so the strip will be fine. The tub surround will be a bit different too so what I suggest is measuring on the tub wall the tile heights and stand back and look at it. Use a pc of tape the approx width of the strip and tape it or draw it on the tub wall s prior to tiling. Will give you a better idea. Also take into account any fixtures you may put in such as a shampoo/soap shelf. Any questions you can e mail me through my avatar and check my qualifications there. I ve also have down 100s of tub surrounds. GL

- Q: I‘m having a small bathroom remodled. The floor isn‘t perfectly rectangular, there are some uneven areas because of the tub. I would like the opinion of a profession tiler (should there be one put there, somewhere)...should the floor tiles always be centered, or start lined up against a wall? Also, should the grout be completely dry before sealing it? Thanks.

- You start from the centre always and lay tiles towards the edges. At the tub you take off the removable side and put the tiles under the tub a few inches. Refit the side but will need to take off some of the bottom edge. Get the first tiles exactly square and away you go. Grout should be dried out for at least 3 days before adding a sealant. Also before laying tiles cover the area with 6mm ply wood so that the whole floor is even otherwise you will/might get uneven tiles. Happy New Year.

- Q: i‘m having an investigatory project and its all about making tiles out of broken glass and rice hull. help me pls.

- I'm not at all familiar with tile making using rice hulls, but certainly I'm curious. I've installed multiple thousands of sq. ft. of tile; as well as having sculpted clay to fire in my kiln. You don't state that the glass will be in chip form, or has to be fired/melted. I profess some ignorance but it seems that in some way, the process would require a Forge or kiln, and when and how would the rice hull be infused,,,and more importantly how might one expect Rice Hull to stand up to the same temps as it would take to liquify glass? Steven Wolf

- Q: how do i do the measuring and lay out on a 10 foot by 6 foot floor when laying the tiles diagonally?

- A 10x6 room requires 60 square feet of tile to cover the floor. On a normal square to the walls pattern, I would order 10% more tile to cover waste. On a diagonal pattern, you will have more waste. I would order 15% to 20% more tile to cover waste. To set up to lay the tile, I start by picking the most obvious sight line in the room - maybe from the next room through the door and chalk a line perpendicular to the far wall along that sight line and parallel to the side wall. Then you chalk a line 45 degrees wall to wall through the center point of the center of the first line. This is your 45 degree pattern. Chalking a line wall to wall 90 degrees from the second chalk line through that same center point gives you your grid pattern to set your tile from. Ignore the first line - that was for reference only - line two and three are the lines you set your tile from. Set out tile dry with spacers to see if you like the effect. I will sometimes set out all of the whole tile possible in the room and walk around to see if it looks good. If it doesn't look right or you end up with too small pieces along the edges or in the doorways, you can move your initial start point and rechalk your lines.

- Q: What type/color tile will mesh with this wall coloring?

- Tile okorder /

- Q: I absolutely hate the tile in our main bath, its coming up and in a few places there is no grout, so its basically looks awful. The bathroom is my dogs fav place to be and i am constantly sweeping the gobs of hair that get in the cracks. Are there any suggestions for an eay fix? How much trouble would it be to just fill the cracks with grout and put stick tile over it? Would that be a ridiculous idea?

- YOUR IDEA IS BRILLIANT AND RELATIVELY INEXPENSIVE

- Q: Someone told me its called tile- something) I know it has a nic-name, do you know it?

- imperial highway maybe

- Q: Can anyone tell me what type of tile this is? Name?

- All i will say is: its normally not a best thought to put it correct on top. It turns into extra seemingly for it to come up. After which the approach of taking over a layer of laminate and a layer of ceramic tile could be that a lot tougher when it happened. I consider the one technique to make that work with out taking up the ceramic tile is to make an air tight seal between the two. I couldn't give you any strategies on how to try this though.

- Q: Wondered what people‘s experiences were of the above in kitchens. The kitchen leads out into the back garden so the floor will be walked on an awful lot. Would flooring last or look as good after a year or would tiles be the way to go. Any info would be great before I make a purchase.Thanks

- If you compare cost, tile flooring seems costlier than wooden flooring. The cost depends entirely on the quality of the materials. Sometimes, wooden flooring can be costly too if the woods are of top quality. And if you compare the life of wooden and tile flooring, I believe it depends on how you use and care. If you can care it properly, it will last longer. So, overall I would say that both the materials can be good for the kitchen whether it’s wooden or tile flooring. It depends on your requirement such as the kind of style or decoration you want in your kitchen.

Send your message to us

Glazed Floor Tile 300*300mm Item No. CMAX3A340

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1683 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches