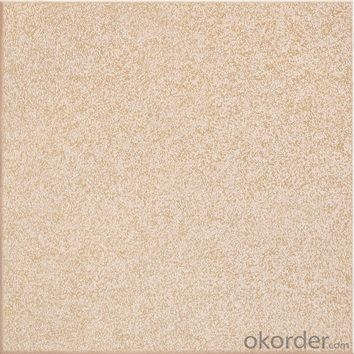

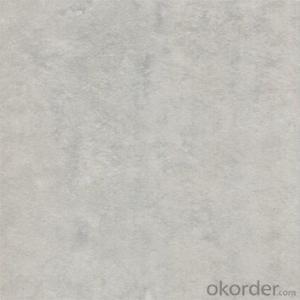

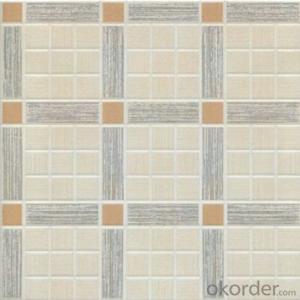

Glazed Floor Tile 300*300 Item Code CMAXRA4477

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Brief Introduction

Glazed Floor Tile 300*300mm, CMAXRA4477 is one of the popular models of 300*300 mm glazed floor tile, which is wildly used for floor of kitchen and bathroom as well as balcony and bedroom. These tiles could create an antique feel of classic European life, just like living in the old times of nature and pastoral life.

Product Features

Glazed Floor Tile

Grade AAA available only

Strict quality control system

Much competitive price in the whole supplying market

Standard export packing: Paper Carton+ Solid Wooden Pallet

Fast production arrangement

OEM service could be offered based on the actual requirement

Comprehensive Marketing support on samples, catalogues as well as carton designing

Professional sales team who could offer service during the whole purchasing process, from the beginning to the ending.

Product Specification

Tile Type: Dry-Pressed Tile

Quality standard: GB/T4100-2006, ISO13006, ISO9001

Water Absorption Rate: 3% -- 6%

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.15%

Edge Straightness: ±0.15%

Packing Information (For 27.5 Tons heavy 20’Fcl)

11pcs/Ctn, 18.5kg/Ctn,1472Ctns/20’Fcl, 1457.28m2/20’Fcl

Production Line & Package

FAQ

1. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton. If the order quantity is over 5 containers, we could print the carton of client’s design for the final packing.

2. Could you company supply polished porcelain tile?

—— Yes. We could supply various kinds of polished porcelain tile, with size 60*60, 80*80, 100*100 and 60*120.

3. For Ceramic Glazed Floor Tile, what are the regular sizes?

—— The regular sizes are 30*30, 40*40 and 45*45.

- Q: I now want to match the tile and extend it into my living room and dining area. How would I go about finding the same tile?

- Can you contact the company that laid the tile? Do you remember how you picked it out? Catalogue, Store? Even if you find the name, it might not be a perfect match after all this time. I do my own tiling and I always buy extra in case of repairs later. Storing them in the original box gives you the Manufacturer and style #. The tile contractor should have done this as he has no need for any extra tile left over.

- Q: It‘s been a while since I have done tile, but I remember we used to use sheetrock to cover the floor or for back splash wall, however I don‘t remember what it was used for. Is there special cases when you need to use it or do I need to use it every time? What is the purpose to use the sheetrock?Please help. Thanks.

- It may have been sheetrock that you remember but more than likely it was some type of special backer product that resembled Sheetrock but was made specifically for use under tile. There are several types available at Lowe's like hardibacker or durarock. Both of these products are designed to be placed on the surface to be tiled before the tile is applied and act to stiffen the substrate. In other words they make the surface that the tile goes onto into one big solid piece as opposed to several sheets of plywood. The benefit of this is that is keeps the tiles from moving in relation to each other which will cause the grout lines in between them to crack and gap. These products are generally put down, when tiling floors, on top of a layer of mortar same as you spread mortar to hold the tiles down. Ans then these backer boards are nailed down with roofing nails and the joints are mortared and usually taped like drywall joints are. Then more mortar is spread on top of these boards and the tile is set into this mortar. Floors generally use the 1/4 thick backer board and when applying on walls the 1/2 backer is used. Just nail to the studs and paint with a waterproofing paint then mortar and apply tiles. Good Luck.

- Q: What is the best brand of domestic tiles?

- What is the best brand of domestic tiles? Dongpeng tiles good! Here, we introduce you to the decoration industry within a black technology, Naluotu diamond grinding stone. Now the decoration can be no ceramic tiles, and can be used cement diamond grinding stone and cast stone grinding stone instead of tiles, cement diamond grinding stone and the whole stone grinding stone seamless, on-site pouring, seamless no bacteria breeding, diamond grinding stone But also can release negative oxygen ions, people relaxed and happy. Seamless cement grindstone and sandstone are made of three materials: Nalut special cement mortar, armor concrete seal curing agent and defender concrete seal curing agent.

- Q: I have a black and white tile floor, and most everything that I have tried has left it very slick even after it is dried. Does anyone know of any homemade product to clean it? I am also willing to try comercial products also. I am tired of my family slipping.

- Tile is a smooth surface, it will tend to be a bit slick. The best product to clean tile with is vinegar and water. My son has a tile business and suggests this to the homeowners he does work for.

- Q: I‘m assisting my friend with a property renovation and I need to know with tiles to buy. Can you guys help me out?

- I trust you're talking about flooring for a retail situation. Any decent floor tile works fine, I'd suggest something with a rough texture, for safety in case of wet situations -- spills, rain being tracked in, etc. Outlet stores can be found which offer excellent value, but limited selection -- retail finish out usually is heavily price driven, so look for bargains. Large tile for large spaces, smaller but not too small for smaller spaces. If you buy 2 different sizes (must be same thickness), you can easily make a pinwheel pattern by placing a big tile on the floor then putting small tiles around the 4 corners, and set big tile into the created corners (play with them a bit, and you'll figure it out). If you use a pinwheel, calculate the number of each tile needed by figuring the ratio of sizes. You'll need an equal number of pieces each size, allow 1/8 to 1/4 inch mortar joints, and remember grout costs more per sq ft than tile, and larger joints require more cleaning. Use darkish grout to minimize cleaning issues.

- Q: Platinum crown tiles ok

- You have not provided the brand we have not tested, to provide you with the choice of tiles under the method, I hope to help you. 1 election origin Almost tiles on the market come from two places: Guangdong and Shandong. Guangdong brick overall quality is better than Shandong brick, domestic brands of ceramic tile origin is also generally from Guangdong, so a simple choice of Guangdong brick. (Shandong bricks are also good quality, but more need to blink of an eye). 2 to see flatness Flatness is very critical, if the flatness is very poor, it is difficult to shop in the edge of each tile are not the edge of the gap, there is not only the impact of visual effects affected, serious and even cause Ge (gè) feet. Method one: the same paragraph of the two tiles on the face of the table, his hands pinching side, observe the other side of the tilt, tilt the smaller, the higher the flatness. (This method is suitable for fully flattened bricks that do not apply to antique tiles and bricks with special craftsmanship) Method 2: a brick vertical placed on the same piece of another flat brick surface, observe the gap between the two bricks, less light, the higher the flatness, the better the quality, in my tested tiles , Nobel's tile flatness is the best, almost no light, we can test their own time to try all four. (This method does not apply to antique tiles)

- Q: The logistics of maintaining my marble tile should be an important consideration when choosing what kind of tile I wish to install. Acidic cleaners can etch the tile, which will then need to be repaired, so watch out for them.How can I Maintain my tile and keep it clean with the proper solutions once it is installed?

- There are belowing guidances need to be taken into consideration while maintaining marble tiles: 1Use a dampened sponge mop without cleaner to clean the tile on a daily basis. 2On a weekly basis, use a different sponge mop with a marble cleaner to mop the tile. 3On a quarterly basis, apply a marble sealer made of polymer resin. 4Use painter's tape to tape around the edges of the tile. 5Mop the tile with a dampened sponge mop to remove any dust or debris. 6Following the manufacturer's directions, pour a small amount of a polymer resin into a disposable cup. Pour the polymer resin over the tile, using the paint spreader to push it back into an even layer. 7Allow the polymer resin sealer to dry according the manufacturer's directions.

- Q: tiles to be applied in tub surround and ceiling

- Thinset. okorder /

- Q: I see Dongpeng ceramic tile on the packaging that write what the site, and then write the OF, OB what, I now Tangshan life, we say now Tangshan Dongpeng brick are Shandong, is that right?

- Carton written to the address, where the same brand where the production of almost different places only factory

- Q: Tao Shiya tile how, the quality of how?

- No matter what kind of tiles, its quality identification is nothing more than wear resistance, water absorption, hardness, color, size and other standards, so you can use the following method to determine its quality. Glazed tiles: with rubber hammer or fingers gently tapping the various positions of glazed tiles, such as the same sound, that there is no sandwich; if the sound is different, the internal may be mezzanine, unqualified. Polished tiles: the same quality of polished tiles, from the side to see the relatively thin brick quality, and good quality polishing polished brightness is relatively high. Whole body bricks: weigh the weight of the brick, the same size of the brick, the weight is better than the light. Good quality brick surface fine, smooth. Ultra-fine powder tiles; ultra-fine powder brick is a new series of tiles. Its distinctive feature is that each piece of pattern is different, but the whole is very coordinated, natural. There is a kind of imitation microfine brick on the market, rough look like a small powder brick, but careful observation will find that it is almost the same pattern every piece. Antique tiles: with nails on the surface of the brick draw, good quality brick will not leave traces. In general, the quality of the antique brick is better quality. Listen to the sound: hand tapping the tiles, if the sound crisp, sweet, then that ceramic porcelain high degree of porcelain, good quality; if the sound boring, cloud turbidity, it shows that the sintering degree is not enough, poor texture. In general, the slower the water, indicating that the greater the density of the floor tile, the better the quality; the other hand, the faster the water, indicating that the floor of the small density, the quality of the tiles on the back of the tiles, watching the water spread after the speed, Poor.

Send your message to us

Glazed Floor Tile 300*300 Item Code CMAXRA4477

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords