Glass Storage Jar HD105

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

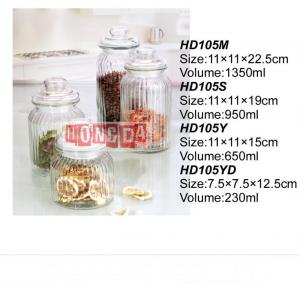

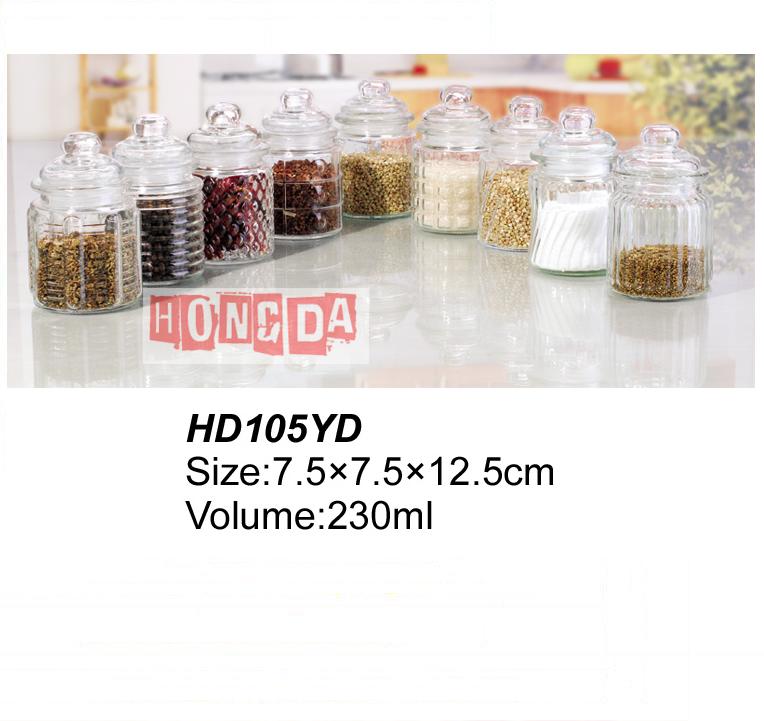

This product is a pressing cover, using food grade rubber sealing ring is to prevent moisture, insects and other advantages, using high quality raw materials, green environmental protection, convenient cleaning. Lines clear, beautiful and generous. There is a high ornamental value.

(Filler belonging to display products, not in the sales range)

HD105M Size:11x11x22.5cm Volume:1350ml

HD105S Size:11x11x19cm Volume:950ml

HD105Y Size:11x11x15cm Volume:650ml

HD105YD Size:7.5x7.5x12.5cm Volume:230ml

- Q: How to distinguish between good and bad glass fiber reinforced plastic?

- Glass steel will be exposed his true strength in the actual use of the process, the quality of glass steel after a few years of use color slightly dim, the whole board intact, no obvious damage, glass steel it would withstand the test of practice, after a few years of use will appear corrosion fracture pores and other obvious damage the board is not so smooth, the color degradation is serious, the overall aging, general glass steel is to be used for twenty years, but two years later will appear glass steel inferior overall aging phenomenon, thus causing great losses to customers.

- Q: Glass fiber raw material price increases, the impact on the glass fiber industry?

- A group of small and medium enterprises will face great pressure, especially the focus will be on reducing costs and expanding production, often ignoring product quality and marketing strategy, in the market competition in a disadvantageous position.

- Q: Is the production of glass materials as thin as possible? Why?

- Glass production is very strict to the granularity of various raw materials, and there is a usable range. Generally, refractory materials are finer, such as sand and feldspar. Some of them are coarse, such as dolomite and limestone. However, the most taboo is "superfine powder""!

- Q: How to seal the glass fiber reinforced plastic mould?

- Considering the type of FRP mould surface is different from the rubber mold so complicated, is generally flat front, so it is recommended to do a Z type mold, pre buried iron screws for back. As long as the screw is properly distributed, it will not leak. Can again, in the mold a good brush coat, also a little gel in the mold parting surface, or glass glue or strips of clay on a concave groove (note the hardness of sludge in winter). The old mold leaks in detail and the sludge is blocked.

- Q: What are the ingredients of photovoltaic solar glass? What's the function of each?

- Furthermore the limestone calcium carbonate and Magnesium Oxide, whose main role is to adjust the viscosity of the glass in a suitable value, so that the glass forming time is shorter or longer, in order to meet the requirements of molding; also the introduction of alumina materials, improve the physical and chemical properties of glass, such as strength, chemical stability, etc.;

- Q: The practice of acid corrosion in tank

- The construction of excellent anticorrosive paint can in a variety of conditions, including exposure to atmospheric environment, can be conveniently carried out in various forms such as painting, brush painting, and meet the requirement of the design of coating thickness and structure.

- Q: What's the difference between three kinds of glass fiber board, epoxy board and FR4 board?

- FR4 is the pure epoxy board of NEMA standard. The normal color should be dark green. This is the color of epoxy. There are also yellow, generally called yellow FR4 called yellow material, white (green) called white material.FR4 is more expensive than epoxy board and fiberglass board cannot confirm the price.

- Q: How is glass made? What material is it made of?.

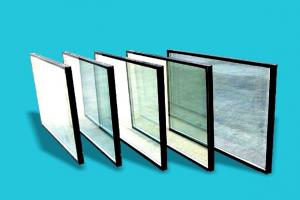

- Bullet proof glass is made of glued laminated material, which is glued together with many pieces of glass or high strength organic board. Generally has the following three layers of structure:Bearing layer: firstly, the layer is broken by impact, and the glass with large thickness and high strength is used. It can destroy warhead or change warhead shape, and make it lose the ability to move forward.Transition layer: the general use of organic adhesive material, strong adhesion, light fastness, can absorb part of impact energy, change the direction of the bullet forward. A very strong and transparent chemical film is sandwiched between laminated glass. This can not only effectively prevent bullet shooting, but also has the properties of surge resistance, explosion resistance, shock resistance and no cracks after impact.Safety protection layer: this layer is made of high strength glass or high strength transparent organic material. It has better elasticity and toughness, can absorb most impact energy, and ensure that the bullet can not penetrate the layer

- Q: What raw material is the front bumper of the car made of?

- Toughened glass is a kind of prestressed glass, in order to improve the strength of the glass, the methods commonly used in chemistry or physics, formed on the surface of glass glass under compressive stress, first offset surface stress force, so as to improve the bearing capacity of reinforced glass, its wind, cold, impact etc.. Notice that it is different from fiberglass.

- Q: What's the connection between tempered glass and float glass?

- Float glass is the raw material for processing toughened glass. It is answered in your question!

Send your message to us

Glass Storage Jar HD105

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords