Glass Wool Reinforced Concrete Sheet/Well Fiber Glass

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

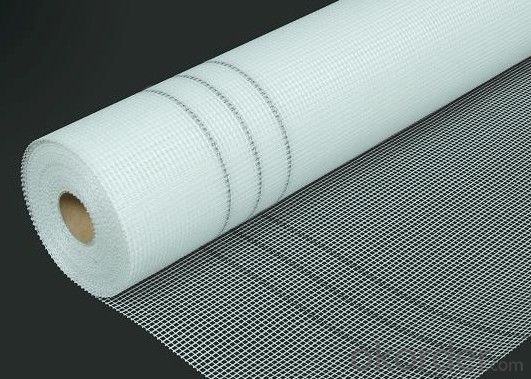

| Place of Origin: | Henan, China (Mainland) | Brand Name: | cnbm | Model Number: | EW7532 |

| Application: | Wall/Roof covering Cloth | Weight: | 250 g/m2 | Width: | 900-1600mm |

| Weave Type: | Plain Woven | Yarn Type: | E-Glass | Alkali Content: | Alkali Free |

| Standing Temperature: | 300°C | Color: | White | Certificate: | ISO9001 |

| Advantage: | waterproof | Length per roll: | 500m | Thickness: | 0.18mm |

| Port: | Any Chinese port | Raw material: | fiberglass yarn |

Packaging & Delivery

| Packaging Details: | Cartons loaded on pallets |

| Delivery Detail: | 30 days after receiving the deposit |

Application

1. All types of thermal insulation and heat protection.

2. Welding blankets and fire curtains.

3. Expansion joints.

4. Basic cloth for coatings and laminations.

Specifications

glass fiber reinforced concrete

Firm mesh and good glue

fiberglass mesh manufacturer

| Fiberglass mesh grid component | 1.glass fiber woven fabric as substrate |

| 2.macromolecular anti emulsion coating | |

| The adventage of fiberglass mesh | |

| 1. good alkali resistance | |

| 2. flexibility and latitude to the high tensile strength | |

| 3. good chemical stability, high strength, light weight | |

| 4. good dimensional stability | |

| 5. strong impact resistance | |

| 6. pest control, fire protection, thermal insulation | |

| 7. other features | |

| Fiberglass mesh usage | |

| 1. wall reinforcing material | |

| 2. reinforced cement products | |

| 3. internal and external wall insulation | |

| 4. granite, marble, mosaic special mesh back paste network | |

| 5. waterproof cloth, asphalt roofing | |

| 6. reinforcing materials of plastics, rubber products | |

| 7. fire board | |

| 8. the grinding wheel base | |

| 9. highway pavement with geogrid | |

| 10. building sealing tape |

Our Services

1. Your inquiry will be replied within 24hours

2. Well-trained and experienced staffs to answer all your inquiries.

3. All our products have 1-year warranties.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.

- Q: What is semi-rigid glass wool board

- Semi-rigid glass wool is a high-density glass wool, is made in the ordinary glass wool on the basis of processing packaging

- Q: Rock wool board and glass?wool?board, which is more harmful to human body?

- Many countries have banned such hazardous substances. The security of glass wool board is high for the asbestos fibers can cause asbestosis, pleural mesothelioma and other diseases.

- Q: How does the glazed wall in the living room fixed? The top surface of the glazed wall is mineral wool board.

- How does the glazed wall in the living room fixed? The top surface of the glazed wall is mineral wool board.

- Q: What are the applications of centrifugal glass wool board?

- Centrifugal glass wool board is board product with a certain intensity which is made by curing centrifugal glass wool. Whether in high or low temperature environment, it can maintain good heat insulation and sound absorption properties, mainly used for interior wall compartment in advanced architecture, ceiling, heat conservation for iron sheet air duct or aie bellow, sound absorption and noise reduction for studio, machine room and other places.

- Q: Which thermal insulation materials are the best for air-conditioners? Is it rubber and plastic, PEF or glass wool?

- Rubber and plastic is a better choice for conduits.

- Q: Does glass wool equals to rock wool?

- It has advantages of good sound-absorbing , welding and thermal insulation performance, small bulk density, chemical stability, corrosion resistance, and belongs to glass in terms of chemical composition. It is an man-made inorganic fiber, cotton-like material. Glass wool belongs to glass fiber with low thermal conductivity which is a mineral wool. Rock wool is also known as asbestos. Glass wool fiberizes molten glass.

- Q: Sound absorption and sound insulation How is the sound insulation effect of glass wool?

- Glass wool, also known as glass fiber, should be the same with foam and some other materials, which have excellent sound insulation and sound absorption effects, and widely used for partition and sound insulation of functional zone in the decoration. Which is a kind of filling material and auxiliary material in the decoration, in addition to considering costs, its practicability should also be considered, and it's also very important to select the right application places. I hope my answer can help you.

- Q: What are the differences between rock wool and glass wool?

- Rock wool board has short silk and glass wool has long silk,

- Q: Does mineral wool, rock wool and glass wool board refer to the same kind of board?

- No, mineral wool includes aluminum silicate and other thermal insulation board, main material is mineral stone, the main material of rock wool is basalt and mineral slag. the main material of glass wool is glass, so they are different and have different thermal insulation effect and price, in general, rock wool is common.

Send your message to us

Glass Wool Reinforced Concrete Sheet/Well Fiber Glass

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords