Geotextile Brico Depot Deer Guard / Extruded PP Deer Guard Fence

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic netting plastic mesh breeding mesh

1. Plastic Plain Netting

Colour:white,black,blue and green, client's requirement.

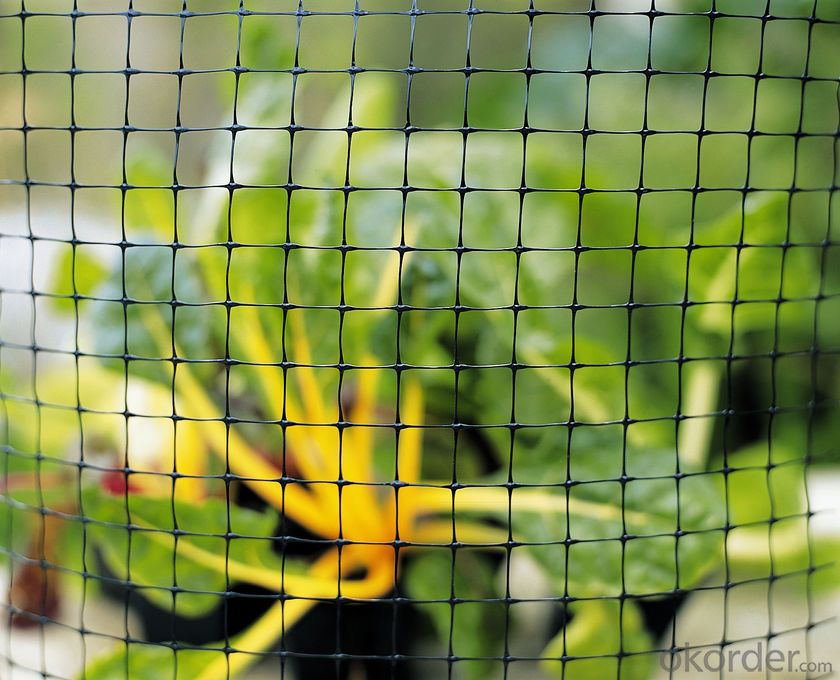

2. Deer fence introduction:

Deer fencing is a very high strength, lightweight, 3.6ft to 7.3ft high deer fence manufactured from high strength polypropylene BOP plastic netting. Deer have a tendency to forage over large areas and the cost effective deer fencing offers a very effective deer control barrier.

The deer fence is black, UV stabilised and rot proof and unobtrusive as it merges into it's background. Deer fencing is very quick and easy to erect and each roll weighs less than 15kg. The Deer Netting should be installed by battening to the fencing posts to ensure the mesh filaments are not damaged.

3. Features of the deer neeting fence:

Deer fence is easy to erect and install

Plastic netting has a mesh hole size of 0.06" ,0.08",0.18",0.19"

The BOP plastic netting has a high tensile strength

Plastic mesh is UV stabilized and chemical resistant

4. Features:

1). Low cost, while has superior strength

2). Has anti-tearing and friction capability

3). Wide range of product availability, some other mesh sizes and weights can also produced as per customers' requirements.

5. Package/Payment/Delivery:

Package: Usually packed by rolls in plastic film bags with labels inside and then loosely loaded in the container

6. FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How do geotextiles improve the performance of geofabrics?

- Geotextiles improve the performance of geofabrics by providing additional strength and stability to the materials. They act as reinforcement layers, preventing the soil particles from shifting or migrating, thus enhancing the overall durability and functionality of geofabrics in various civil engineering applications.

- Q: Can geotextiles be used in underground construction applications?

- Yes, geotextiles can be used in underground construction applications. Geotextiles are commonly used in underground construction for various purposes such as soil stabilization, drainage, filtration, and erosion control. They help to improve the overall performance and longevity of underground structures by providing reinforcement and preventing the migration of fine particles.

- Q: How do geotextiles help with slope stabilization?

- Geotextiles help with slope stabilization by providing reinforcement and erosion control. They are placed on slopes to prevent soil erosion, retain soil particles, and distribute loads evenly. The geotextiles act as a barrier, allowing water to pass through while preventing the loss of soil particles. This helps to maintain the stability of the slope and prevent slope failure.

- Q: 300g / m2 geotextile permeability coefficient is generally how much?

- Geotextile cloth short fiber geotextile and long fiber geotextile, the two geotextile permeability coefficient is basically the same. According to the requirements of the national standard 300g / ㎡ geotextile permeability coefficient for the K * (10 negative side ~ 10 negative three power), K is between 1.0-9.9 values. From the indicators can be seen 300g / ㎡ specifications of the geotextile has a good water filter, can be used for water, filter them.

- Q: Can geotextiles be used for separation of different soil layers?

- Yes, geotextiles can be used for the separation of different soil layers. Geotextiles are permeable fabrics that can be placed between different soil layers to prevent mixing and maintain their distinct properties. They act as a barrier, allowing water to pass through while preventing the migration of fine particles. This separation helps in enhancing the stability and performance of the soil layers, reducing the risk of settlement and maintaining the integrity of the construction project.

- Q: How do geotextiles contribute to soil filtration?

- Geotextiles contribute to soil filtration by acting as a physical barrier that allows water to pass through while filtering out sediment and other contaminants. They help to prevent soil erosion, improve water quality, and enhance the overall stability and sustainability of soil.

- Q: Geotextile manufacturers are what industry

- Petrochemical! Raw materials are all extracted from the oil out of the glial particles!

- Q: Can geotextiles be used in embankment reinforcement?

- Yes, geotextiles can be used in embankment reinforcement. Geotextiles are often used in civil engineering projects to improve the stability and strength of earth structures, including embankments. They can effectively distribute loads, provide soil separation and filtration, and enhance the overall performance and longevity of embankments.

- Q: How do geotextiles help with subgrade separation in pavement systems?

- Geotextiles help with subgrade separation in pavement systems by acting as a barrier between the subgrade soil and the overlying base and subbase layers. They prevent the mixing of these layers, which can lead to contamination and reduced structural integrity of the pavement. Additionally, geotextiles enhance the load distribution and drainage capabilities of the pavement system, improving its overall performance and longevity.

- Q: How are geotextiles installed?

- Geotextiles are typically installed by laying them over the desired area and securing them with stakes or pins. They can also be anchored using sandbags or rocks, depending on the specific application. The installation process may involve preparing the ground, removing any debris or vegetation, and ensuring proper alignment and overlap of the geotextile rolls.

Send your message to us

Geotextile Brico Depot Deer Guard / Extruded PP Deer Guard Fence

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords