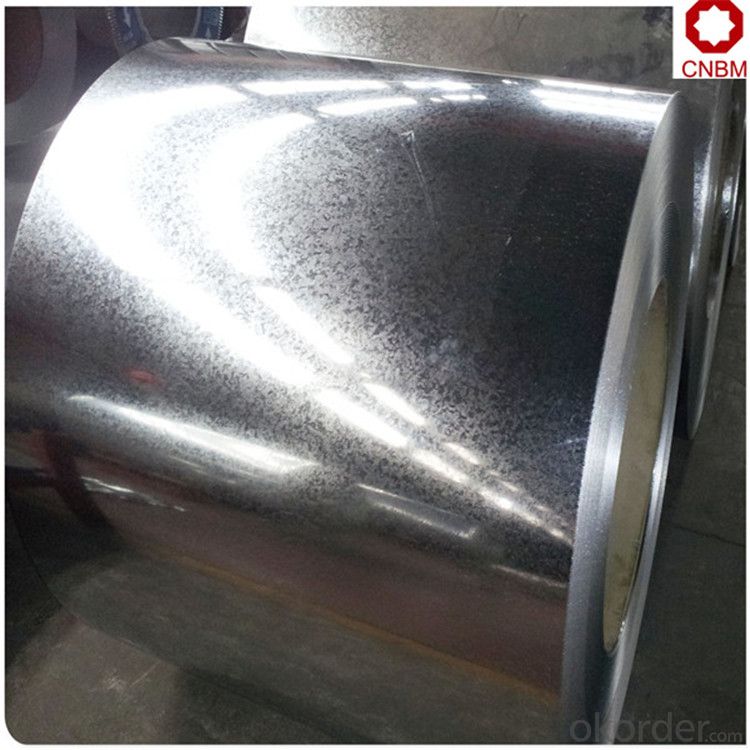

Galvanized steel strip coil in SGCC hot-dipped

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 32634 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Standard and Grade :

Hot-dip galvanized steel coils | ||||

ASTM A653M-06a | EN10327:2004/ 10326:2004 | JISG 3302-2010 | AS-NZS 4534-2006 | |

Commercial quality | CS | DX51D+Z | SGCC | G1+Z |

Structure steel | SS GRADE 230 | S220GD+Z | SGC340 | G250+Z |

SS GRADE 255 | S250GD+Z | SGC400 | G330+Z | |

SS GRADE 275 | S280GD+Z | SGC440 | G350+Z | |

SS GRADE 340 | S320GD+Z | SGC490 | G450+Z | |

SS GRADE550 | S350GD+Z | SGC570 | G550+Z | |

S550GD+Z | G550+Z | |||

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

Company Information

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

- Q: What are the different types of surface defects in steel coils?

- Some common types of surface defects in steel coils include scratches, pits, rust, scaling, laminations, and waviness.

- Q: I live in the Black Hills and I need to re-side my cottage. I like the look of vinyl. I've heard pros and cons about both steel and vinyl. Is steel really that easy to dent? It just doesn't look as 'clean' as vinyl. Also what 3 color combos do you like? My cottage has shutters.

- I'd like to know why you need to re-side it. I would get vinyl because it will not need painting as soon as steel.

- Q: i was giving this old knive. the knife part is stainless steel and has a couple rust spots but im not sure that the handle is (i think stainless) but it has this un smooth surface i dont think its rust because its not brown. would rubbing alcohol help clean it?

- Your answers are all good but I would mention that we have a set of Sabtier chef knifes that were expensive these look to be stainless but are not quite as I think that marine grade stainless does not make the best cutting edge and my guess is that your knife would contain a greater amount of carbon better cutting edge but not so stainless. As a carpenter that has to sharpen cutting tools I add that I have never had a chisel or plane blade that was made of stainless steel and the best edges I obtain are with vintage tools. Bar Keepers friend is great as is 00 grade wire wool but do not put your knife through the dishwasher as the cleaning tabs will pit the surface of your knife.

- Q: How are steel coils used in the production of wind turbine components?

- Steel coils are used in the production of wind turbine components for their strength and durability. These coils are typically formed into various shapes and sizes to create structural elements such as towers, frames, and foundations. The steel coils are also used to manufacture critical parts like rotor blades, gearboxes, and generator housings, ensuring the turbines withstand harsh environmental conditions and operate efficiently.

- Q: Can steel coils be coated with PVC?

- Yes, steel coils can be coated with PVC. PVC coating provides added protection against corrosion and increases durability and longevity of the steel coils.

- Q: The difference between aluminized color steel roll and ordinary color steel roll

- Substrate selection: AZ150 (aluminum zinc content 150g/m2); G345A high strength galvanized steel sheet (55% aluminum, 43% zinc and 1.6% silicon) corrosion resistance data: 5%NaCL 35 DEG C, 1000Hrs, Field good, Scribe, No, Blister, 2mm belowQ.U.V: 2000hrs, MAX.2 color, light to keep the rate above 90%, the above data show that aluminum zinc coated board (AZ150, G345A, PVDF) is very suitable for the extreme environment of buildings or other facilities, highly corrosion resistance and weather resistance, and the major steel plate can ensure the service life of 20 years. In addition, high strength steel has been widely used abroad, and it has good economic performance, and it is also the domestic development trend.

- Q: How are steel coils used in the manufacturing of garage doors?

- Steel coils are used in the manufacturing of garage doors as they provide the necessary strength and durability required for the door panels. These coils are formed into various shapes and sizes to create the panels, which are then coated and insulated to enhance their performance and appearance. The use of steel coils ensures that the garage doors are sturdy, long-lasting, and able to withstand the daily wear and tear associated with regular use.

- Q: What is the maximum diameter of a steel coil?

- The maximum diameter of a steel coil varies depending on the specific type and thickness of the steel, as well as the capabilities of the manufacturer's equipment. However, in general, steel coils can have diameters ranging from a few inches to several feet.

- Q: Can steel coils be coated with abrasion-resistant materials?

- Yes, steel coils can be coated with abrasion-resistant materials. These materials are specifically designed to provide a protective layer against wear and tear caused by friction, impact, or other forms of abrasion. Coating steel coils with abrasion-resistant materials helps to enhance their lifespan and durability, making them suitable for various applications that involve high levels of abrasion or mechanical stress.

- Q: How do steel coils contribute to strength and durability in manufacturing?

- Steel coils contribute to strength and durability in manufacturing in several ways. Firstly, steel is an inherently strong material due to its high tensile strength, which allows it to withstand heavy loads and resist deformation. When steel is coiled, it undergoes a process called hot rolling or cold rolling, which further enhances its strength and durability. During hot rolling, the steel is heated to high temperatures and then passed through a series of rollers, which compress and shape it into a coil. This process aligns the grain structure of the steel, making it more uniform and reducing internal stresses. The result is a stronger and more resilient material that can withstand the rigors of manufacturing processes such as bending, stamping, and forming without losing its structural integrity. Cold rolling, on the other hand, involves passing the steel through rollers at room temperature. This process not only increases the strength and hardness of the steel but also improves its surface finish. Cold-rolled steel coils are known for their smooth and uniform appearance, making them ideal for applications where aesthetics are important. Furthermore, steel coils can be coated with various protective layers to enhance their durability. These coatings, such as zinc or polymer-based coatings, act as barriers against corrosion, moisture, and other environmental factors that can weaken the steel. By preventing rust and degradation, these coatings extend the lifespan of steel coils and the products they are used in, making them more durable and cost-effective in the long run. In summary, steel coils contribute to strength and durability in manufacturing by providing a strong and resilient material that can withstand heavy loads and resist deformation. The hot rolling and cold rolling processes further enhance the strength and uniformity of the steel, while protective coatings help to prevent corrosion and extend the lifespan of the coils. Overall, steel coils are essential components in manufacturing that contribute to the strength and durability of a wide range of products.

Send your message to us

Galvanized steel strip coil in SGCC hot-dipped

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 32634 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords