Galvanized Steel Sheet in Ciols with Prime Quality Best supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3333 m.t.

- Supply Capability:

- 111111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

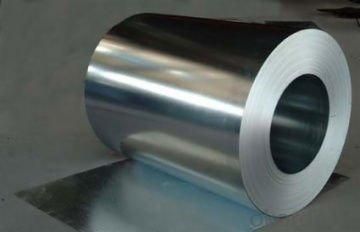

1.Structure of Galvanized Steel Coil Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

2.Main Features of the Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• High corrosion resistance

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

3.Galvanized Steel Coil Images

4.Galvanized Steel Coil Specification

Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

Grade : SGCD,SGCH, Q195,DX51D

Zinc coating :40-180g( as required)

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

Coil id:508mm/610mm

Coil weight: 4-10 MT(as required)

Surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

5.FAQ of Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

3.How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Why does steel with several composites have a greater hardenability from quenching than low carbon steel alloys?Any help would be great

- Bit tricky to explain and I don't know muh about it but steel on its own has lost of gaps in it ( the molecular structure) and when carbon is added thos gaps are filled, I think of it like this: it is easier to punch through expanded polystyrene( with all the little balls) than unexpanded(just a lump of plastic) as the balls are not properly joined and have air pockets between them.

- Q: I bought this Brinks pad lock and it says boron steel on the lock. I was just wondering what exactly is boron steel and how hard/tough is it?

- Boron steel is rather hard, it is by no means titanium, but certainly better than mild steel. However, as with all metals, hardness is inversely proportional to flexibility, meaning that a good solid whack with a sledge hammer could crack your lock.

- Q: What is the standard width of steel coils?

- Depending on the industry and application, the width of steel coils can differ. Generally, steel coils have a standard width range of 36 to 72 inches. The actual width is influenced by various factors including the type of steel, intended use, and the machinery involved in processing and handling the coils. To ensure the appropriate width for a specific steel coil application, it is crucial to refer to industry standards and specifications.

- Q: How do steel coils withstand extreme temperatures?

- Steel coils are able to withstand extreme temperatures due to their unique composition and manufacturing process. Steel, the primary material used in coils, is an alloy of iron and carbon that possesses excellent thermal properties. Its high melting point, which can reach up to 2,500 degrees Fahrenheit (1,370 degrees Celsius), allows it to remain structurally stable under intense heat. Furthermore, steel coils are often subjected to a process called annealing, which involves heating the steel to a specific temperature and then slowly cooling it down. This annealing process helps relieve internal stresses within the steel, making it more resistant to thermal expansion and contraction. By reducing the presence of internal defects, annealing also enhances the steel's overall strength and durability, allowing it to better withstand extreme temperatures. Moreover, steel coils are often coated with protective layers to provide additional resistance against temperature variations. These coatings, such as galvanized or zinc coatings, act as a barrier between the steel and the external environment. They help prevent oxidation, corrosion, and other forms of degradation that can occur when exposed to extreme heat or cold. In summary, steel coils are able to withstand extreme temperatures due to the inherent properties of steel, the annealing process that relieves internal stresses, and the protective coatings that provide an extra layer of resistance. These factors work together to ensure that steel coils remain structurally stable and maintain their performance even in the harshest temperature conditions.

- Q: How are steel coils used in the production of electrical relays?

- Steel coils are a crucial component in the production of electrical relays as they are used to create a magnetic field. When an electrical current passes through the coil, the magnetic field is generated, which then attracts or repels a movable contact, allowing the relay to switch on or off an electrical circuit. Hence, steel coils play a vital role in the functioning of electrical relays by facilitating the control of current flow.

- Q: How are steel coils protected from chemical damage?

- Steel coils are protected from chemical damage through various methods such as applying protective coatings, using corrosion inhibitors, and storing them in controlled environments to minimize exposure to harmful chemicals.

- Q: and is that different from the components of steel

- Making steel is very energy intensive. Mining the raw ore requires a lot of machinery that uses fuel or electricity . Transporting the ore requires a lot of fuel. Refining not only uses a lot of electricity but coal is added to change the iron ore into steel.

- Q: How are steel coils processed into finished products?

- Steel coils are processed into finished products through a series of steps including uncoiling, leveling, cutting, shaping, and surface treatment. The uncoiling process involves unwinding the steel coil to create a flat sheet. Next, leveling machines remove any unevenness in the sheet's surface. Then, the sheet is cut into desired lengths or shapes using cutting machines. Shaping processes such as bending, rolling, or stamping are performed to achieve the desired product form. Finally, surface treatment techniques like galvanizing, painting, or coating are applied to enhance the product's durability and appearance.

- Q: Can steel coils be recoiled?

- Yes, steel coils can be recoiled. The process of recoiling involves rewinding the steel coil onto a different reel, typically to adjust the coil size or to improve its shape.

- Q: Is there a chemical that can be applied (spraid, brushed, adhere) to a steel surface to decrease the heat conductive properties of the metal (so it doesn't heat up as quickly)?Thanks in advance!

- There is, but I don't know what it is made out of. It is probably some fireproof, foam material which acts like insulation. I doubt it is designed to resist abrasion however. Most things which adhere to metal surfaces are not flameproof, and those which do resist fire are not good insulators. For example, the ceramic coating of appliances like stoves and washing machines adhere very well and are fire resistant, but do not insulate. It was the failure of the steel insulation which caused the collapse of the world trade centers. The impact of the airplane tore away all the insulation on the supporting struts of the building and then the fire caused the steel to soften and break. Steel was once insulated by wrapping it in asbestos cloth and then applying plaster over this to form a shell. It did not actually adhere to the steel but it did insulate it, and was fireproof. However asbestos is a cancer hazard and a lot of old buildings are being stripped of their asbestos as a safety precaution. The asbestos can be replaced with fiberglass which is usually duct taped together.

Send your message to us

Galvanized Steel Sheet in Ciols with Prime Quality Best supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3333 m.t.

- Supply Capability:

- 111111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords