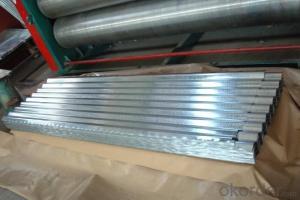

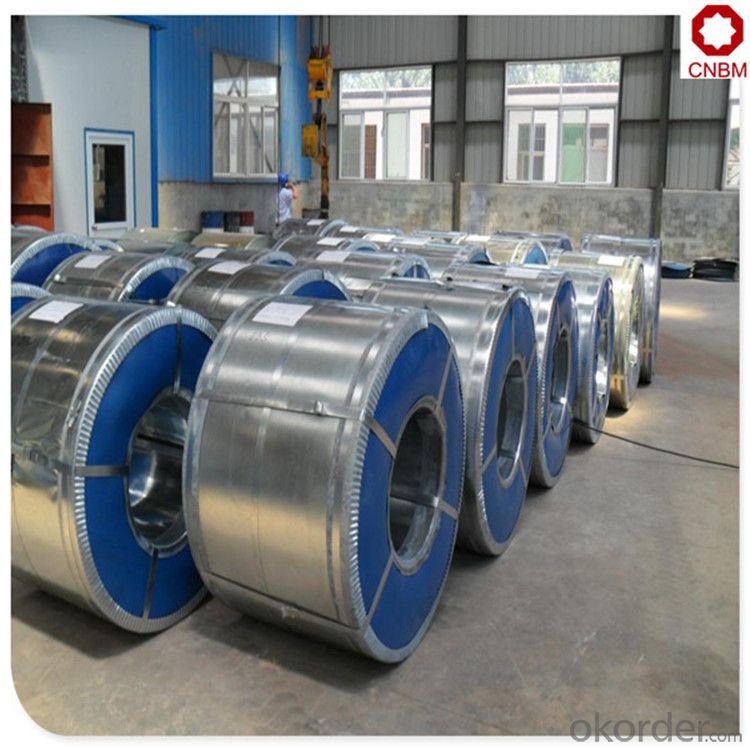

Galvanized steel coil for roofing sheet Dx51d z100

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 35687 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

Standard and Grade :

Hot-dip galvanized steel coils | ||||

ASTM A653M-06a | EN10327:2004/ 10326:2004 | JISG 3302-2010 | AS-NZS 4534-2006 | |

Commercial quality | CS | DX51D+Z | SGCC | G1+Z |

Structure steel | SS GRADE 230 | S220GD+Z | SGC340 | G250+Z |

SS GRADE 255 | S250GD+Z | SGC400 | G330+Z | |

SS GRADE 275 | S280GD+Z | SGC440 | G350+Z | |

SS GRADE 340 | S320GD+Z | SGC490 | G450+Z | |

SS GRADE550 | S350GD+Z | SGC570 | G550+Z | |

S550GD+Z | G550+Z | |||

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

Certificate:

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development

- Q: I'm talking about the sort of carbon fiber that's used in the auto industry (mostly in supercars).If an object made of steel were to be copied by an exact same object, but made of carbon fiber - how lighter would the carbon fiber object be?For example, if a table is made of steel and it weighs X, how much will it weigh if it were made of carbon fiber?Thanks.

- by 6L8

- Q: How are steel coils used in the manufacturing of storage tanks?

- Steel coils are used in the manufacturing of storage tanks as they serve as the primary material for constructing the tank shell. The coils are processed and shaped into cylindrical sections, which are then welded together to form the tank. This ensures strength, durability, and leak-proof construction, making steel coils an essential component in the fabrication process of storage tanks.

- Q: I've created something but it's a huge secret. Anyways I need to know everything and anything about steel. Like the iron steel. ANYTHING AND EVERYTHING. Best answer goes to the person with the most correct information. Please this is really important.

- If you want to know everything about steel, there's no way you're going to get an answer on Yahoo that is comprehensive enough. What you want to do is get some books on steel metallurgy, engineering properties of materials, and maybe machine design depending on your application. Topics will include molecular structure, material properties, alloying, stress and strain, work hardening, creep, computing damage and lifetime cycles, corrosion, toughness vs hardness, heat treating, and a ton of others. If you want to sharpen steel, that is a whole topic in itself concerning different blade profiles and their sharpness, edge holding, ease of sharpening, type of grind etc.

- Q: What products can we make with steel (eg Steel strip, rod, bar, rail, tube) How are these made? What can we make from these steel products?Can you please make the answers as detailed as possible you can because i really want to know this really well. Thank you.

- Your okorder (they make steel deck and steel joists) There are thousands of other items routinely produced from steel, including rebar, and all the metal in cars, airplanes, and about a million other things.

- Q: What is stainless steel coil used for?

- Stainless steel coil is primarily used in various industries for its durability, corrosion resistance, and aesthetic appeal. One of the most common applications is in the manufacturing and construction sectors, where stainless steel coils are utilized to produce a wide range of products such as kitchen appliances, cutlery, automotive parts, and architectural structures. The corrosion-resistant properties of stainless steel make it an ideal choice for applications that require resistance to moisture, chemicals, and harsh environmental conditions. Additionally, the high strength and heat resistance of stainless steel coils make them suitable for use in industrial equipment, heat exchangers, and piping systems. Moreover, the aesthetic appeal of stainless steel, with its sleek and modern appearance, is often preferred in the design and production of consumer goods, including furniture, jewelry, and decorative items. Overall, stainless steel coil is a versatile material that finds extensive usage across various industries due to its excellent mechanical properties, resistance to corrosion, and aesthetic versatility.

- Q: What are the main factors that affect the flatness of steel coils?

- The main factors that affect the flatness of steel coils include the quality and consistency of the incoming raw material, the precision of the rolling process, the tension applied during rolling, the cooling and annealing processes, and the handling and storage of the finished coils.

- Q: How are steel coils used in the production of shipbuilding materials?

- Steel coils are used in shipbuilding materials as they provide a versatile and durable solution. They can be processed into various shapes and sizes, including plates, beams, and sections, which are essential components for constructing ships. The coils are often cut and shaped to fit specific design requirements, offering strength and structural integrity to the ship's framework. Additionally, the coils are utilized in the fabrication of various shipbuilding components, such as hulls, decks, bulkheads, and superstructures, ensuring the vessels' resilience and stability.

- Q: what do you think about producebility of low density steel? for example: can density of 1020 steel (or ony others) be decreased without any loss of other properties.

- If a material has a lower density than steel, then it isn't steel.

- Q: Well actually I was just wondering why people were bashing on stainless so much for katanas. I heard that they don't hold their edge as well as carbon steel blades or Damascus steel. So what makes it so inferior to carbon or other types of steels?

- There are many kinds of stainless steel. 440c, 420j, ATS34, and so on. Cold steel uses 420 type steels in several of their products. High carbon stainless steels cut well but edge retention is not very good but that also depends on the heat treating of the metal. I could go on all day but very, very basically stainless steels lack the shatter resistance necessary when stretched to great lengths. This is in part why other steels make far better swords. The stuff sold on QVC is just plain junk. Do not buy a stainless steel sword. A blade made of 440S means it belongs hung on a wall...

- Q: No. Not Stainless steel, I mean STEEL.Not a specific type, but STEEL.Thanks. xo

- Scott, there are 3 types of materials: elements, compounds, and mixtures. Compounds are covalently bonded elements. Compounds and elements are both considered 'pure' substances. Mixtures are not bonded in any fashion. So a steel mixture can have varying amounts of iron, carbon, silica,molybdenum, etc., giving the steel the desired properties (strength, rigidity, rust resistance, etc.).

Send your message to us

Galvanized steel coil for roofing sheet Dx51d z100

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 35687 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords