Hot-Dip Galvanized Steel Roof with Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Roof Description:

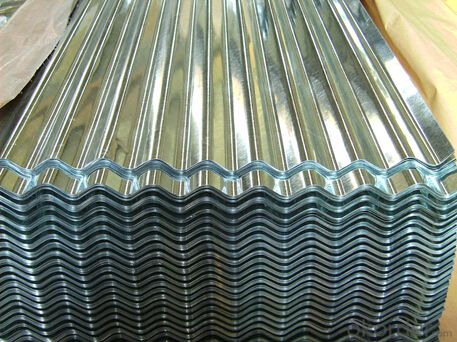

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

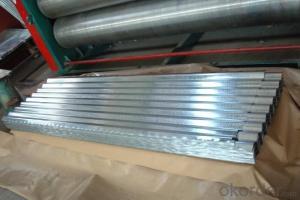

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

- Q: What is the cost of a steel coil?

- The cost of a steel coil can vary depending on various factors such as the size, thickness, grade, and market conditions. It is best to contact a supplier or check current market prices for an accurate cost.

- Q: How can I tell the wear resistance, strength, ect from the name of the steel?how could I tell the difference between 420 and 440 steel. what does the HC in 420 HC steel mean? what do the numbers and letters in s30v steel mean?

- Larry gave a good answer. As for the HC, it means High Carbon.

- Q: Can someone help me...i have a diagram and were supposed to calculate the steel tonnage needed for the pictre. Can someone tell me step by step what i need to do (ex:find area of ...)

- Find the volume of steel and then multiply that by the density of the steel.

- Q: Cast steel welding

- I Use these for cast iron, www.yms .uk/welding-rod-small-pack/2.5mm-cast-iron-welding-rod-small-pack/1951/11612/detail.asp they are expensive when compared to welding rods for steel but i find that normal steel ones dont work on cast iron

- Q: Is steel cut really better? The nutritional profiles are nealy identical. Which one has the best flavor??Thanks!

- Steel okorder /

- Q: I saw a 27 sedan and a 27 Pick-up one had wood wheels the other steel, respectively. Witch one was original or were they both original

- Steel wheels were not available on the pickups until 1929. The cars had the options of steel disc or wood spoke wheels in the mid '20's. I'm pretty sure that '27 was the last year the wood wheels were available on passenger cars.

- Q: Im looking to learn guitar and i was wondering if steel strings are too hard to use as a beginner. I am also self teaching so any good lesson books/starting guitar recommendations are welcome !! thanks.

- Steel strings are fine for a beginner. I learned to play on Steel strings and I have always preferred them to nylon strings.

- Q: How are steel coils used in the production of metal buildings?

- Steel coils are used in the production of metal buildings as they are rolled into sheets and then formed into various structural components such as beams, columns, and roof panels. These coils allow for efficient mass production and provide a high-strength and durable material that ensures the structural integrity of the metal building.

- Q: We are going to build a house with a steel frame.Someone told me today that these houses have problems with humidity.Is that true?Please tell me all you know..

- That's a first for me. The only draw back to a steel frame home is the cost, not only in material but also in labor. They do make a great home with proper installation. Make sure your contractor and framing crew have experience with metal frame construction. There is some differences in building codes, etc. Good Luck and happy building.

- Q: We all know that when we drop a small steel ball (size 3mm diameter; weight 1.10 grams) and a paper (size 11.7 inches length and 8.3 inches breadth; weight 4.5 grams) from a height. The steel ball will win the race to the ground due to its aerodynamic structure.Now imagine the same steel ball with the same weight converted to the structure similar that of paper. What will be the result? Which object will fall first; steel sheet or paper?

- In okorder /... 11.7x8.3 inch paper 97.11 square inches 0.062651488 sq meters at 4.5gm is a non-standard 19 pound bond ledger paper, but that is OK, because at least it is in range. 38 gauge steel sheets are about the thinnest that hold their structure 0.00625 thick 1221 g/m? or, at 11.7x8.3 76.5grams So, with this data at hand we can better visualize the situation. Paper of 0.00625 thick in the size shown is 35# paper 131.68 g/m? 8.25grams Steel is higher in density than paper, so you cannot get the same size and air flow without it being lighter in weight than the steel and the air resistance would be lower for the heavier item, so steel of the same shape and thickness as paper falls faster. Suppose you want paper heavier than steel for the same area, then the thickness increases. Will a steel sheet 0.00625 thick and 11.7x8.3 inch size 76.5gm fall faster or slower than a 9 or 10 times thicker paper sheet? If it was able to hold flat in each type the thicker paper should get more backflow behind it aerodynamically and fall faster than an equal weight thinner steel sheet as my guess, but I don't have those numbers. The steel will always be heavier than the paper for the same exact shape and thickness by about 9x. My answer here is difficult, but the question has some flaws to think about.

Send your message to us

Hot-Dip Galvanized Steel Roof with Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords