Galvanized Razor Barbed Wire Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Razor Barbed Wire

1. Product description

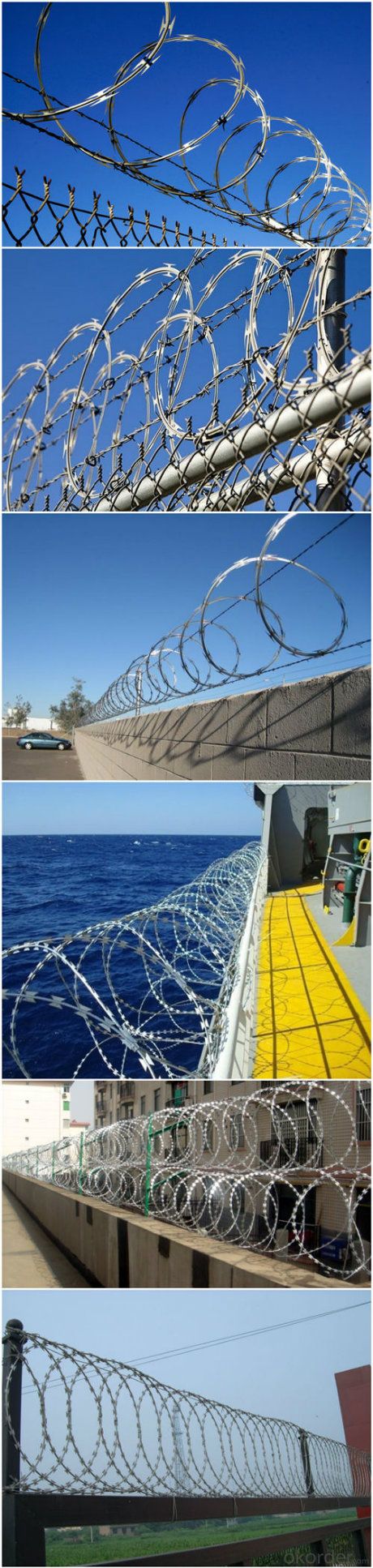

Razor barbed wire is a high security fence system, designed to prevent intrusion along perimeter barriers, it is always fabricated from galvanized or s.s. and high tensile wire.

| Razor barbed wire information | |

| Product name | Razor barbed wire/ Razor wire |

| Country of origin | Anping county, Hebei province, China |

| Application | Military, Prison, School etc |

| Material | Galvanized or S.S. wire |

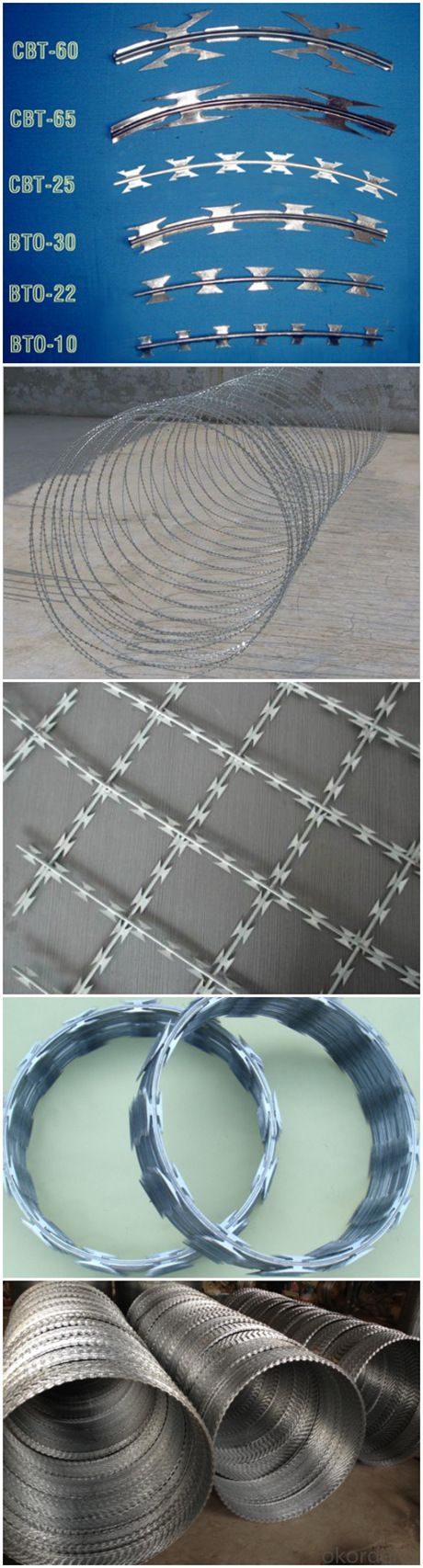

| Type | BTO, CBT |

| Razor thickness | 0.5 ± 0.05mm |

| Diameter | 2.5mm |

| Razor length | 10mm, 12mm, 18mm, 22mm, 30mm |

| Razor width | 13mm, 15mm, 18mm |

| MOQ | 3 Ton |

| Certificat | ISO9001, SGS |

| Packing | Pallets, Carton |

| Delivery time | 10-15 days after deposit |

| Shipping | By sea for bulk order By air/express for small order or samples |

| Payment | T/T, L/C, Western union |

| Express | DHL, TNT, UPS, FEDEX, EMS |

| Remark | Free samples could be supplied Customer order available |

2. Specifications:

| Razor type | Razor thickness (mm) | Wire diameter | Razor length | Razor width | Razor space |

| BTO-10 | 0.5 ±0.05 | 2.5 ± 0.1 | 10 ±1 | 13 ± 1 | 26 ± 1 |

| BTO-12 | 0.5 ±0.05 | 2.5 ± 0.1 | 12±1 | 15 ± 1 | 26 ± 1 |

| BTO-18 | 0.5 ±0.05 | 2.5 ± 0.1 | 18 ±1 | 15 ± 1 | 33 ± 1 |

| BTO-22 | 0.5 ±0.05 | 2.5 ± 0.1 | 22 ±1 | 15 ± 1 | 34 ± 1 |

| BTO-28 | 0.5 ±0.05 | 2.5 ± 0.1 | 28 | 15 | 45 ± 1 |

| BTO-30 | 0.5 ±0.05 | 2.5 ± 0.1 | 30 | 18 | 45 ± 1 |

| BTO-60 | 0.6 ±0.05 | 2.5 ± 0.1 | 60 ±2 | 32 ± 1 | 100 ± 2 |

| BTO-65 | 0.6 ±0.05 | 2.5 ± 0.1 | 65 ±2 | 21 ± 1 | 100 ± 2 |

Ex. Dia. | No. of Turns | Standard Covering Length | Production Model | Remarks |

450mm | 33 | 8M | CBT-65 | Single coil |

500mm | 41 | 10M | CBT-65 | Single coil |

700mm | 41 | 10M | CBT-65 | Single coil |

960mm | 53 | 13M | CBT-65 | Single coil |

500mm | 102 | 16M | BTO-12.18.22 | Cross type |

600mm | 86 | 14M | BTO-12.18.22 | Cross type |

700mm | 72 | 12M | BTO-12.18.22 | Cross type |

800mm | 64 | 10M | BTO-12.18.22 | Cross type |

960mm | 52 | 9M | BTO-12.18.22 | Cross type |

3. Pictures showing:

1) Zhuoda Razor Barbed Wire type and packing

2) Application outside

- Q: I have a universal 02 sensor 4 wire (black, black, white and blue) the stock is white black and grey how do I wire it? thanks :)

- Keep in mind the sensor has a signal wire, a ground wire and a heater wire (or wires). Good luck!

- Q: I have a very old house. I was unhooking the fluorescent light in our kitchen to put a round ceiling light in and the old fluorescent light was plugged into the ceiling (like any regular two pronged electrical plug). How do I wire the ground wire, the line voltage wire, and the neutral wire from the new light so I can plug it into the plug in my ceiling?

- Undersized connector blocks are a particularly user-friendly situation. As you found out, the offered block replaced into ok for an ordinary connection, yet rubbish for greater complicated wiring. Wickes, Wilkinsons, BQ sell strips of connectors for a pair of quid.15amp blocks would be the appropriate suited style of length for 4 wires.

- Q: Wired car radio no sound powered on then wires crossed had to run red straight to battery. Then memory and ground crossed. Now nothing. Checked fuses radio fuse is bad. Will i also need a new wiring harness? Stereo Works fine when hooked up to battery charger.

- Could you rewrite your question and clear it up some. The red wire should go to the ignition on the existing harness in the dash. You were crossing all of those wires? Look at the diagram that came with the deck to know which wires go where. Typical pairs of wires (white and white w#x2F;black stripe or gray and gray w#x2F; black stripe) are for the speakers, red is for power(ignition) I think green is the signal wire and so forth. I don#x27;t know how your wires just get crossed like that? Did you splice them into the wrong ones in the dash?

- Q: I have installed a new wiring harness on my trailer, and two new LED trailer lights. The tail lights work, both turn signals work, but for some reason, I do not have a brake light on the right side. Both lights are grounded to their own post, and I do have a good ground on the coupler of the trailer. If a turn signal and brake light in a 4 wire system are using the same wire (green in this case)- how can one work, while the other is not? Any good ideas? I really appreciate the help.

- assuming it was working ok before....... funky symptoms like that (where you can't imagine the circuit that would make 'em behave like that) almost always turn out to be a weak ground -- like the ground is ok for turn signals because only one side is on at a time, but when you demand enough current to light up both sides, it just ain't happening. you can rule out a ground issue between the vehicle and trailer by hooking a jumper cable between the frames. if that don't produce a change, then run an oversized wire from the fixture direct to the connector.

- Q: Just need a wiring diagram link that shows all wires and possibly steps on installing an aftermarket stereo.

- 300zx Wiring Diagram

- Q: I have 1971 slide in truck camper with 5 way pin wiring wires are red, white ,yellow, black,green.need to know what wire's do what...thanks

- green is common ground. red is usually rear lights, White and yellow are the turn signals Black is the bachk up lights. But it is not standard.

- Q: The spark plug wire on my dirt bike needs to be replaced because it was touching the exhaust and it burned through.I was wondering if the ignition coil and spark plug wire are one piece and need to both be replaced or is there someway to disconnect spark plug wire? They spark plug wire doesn't seem to be pluged in, but it seems to be one piece. Does anyone know?

- if okorder

- Q: what size of wire do i need and is the new fuse box/trip box kept in garage.or where can i get wiring diagrams from

- You will have to get a permit before you start work. It all depends on the power you want out in the garage. If you want to run one 120V circuit, then you'll need to run #10 since it will be a long run to the garage from the house. You will also need a disconnect somewhere where the power comes into the garage. You may want to get a licensed electrician on this one. You don't want to have a fire or someone killed by shock and have the insurance deny the claim because it was faulty wiring and wasn't inspected and authorized. good luck.

- Q: What's the metal wire fabric?Such as title

- Metal wire fabric not only has metal luster, and wear to trim visible, noble, gorgeous, and the fabric has the function of conductive shielding, which is widely used in scientific research, military and medical industries such as electronics, high-tech, high added value.Currently do men and women's windbreaker, jacket, jacket and jacket.

- Q: I am making a lamp shade that calls for bonsai wire. How is bonsai wire different from regular wire and what would be a good substitute for it????

- Bonsai wire may be purchased with coatings of various natural colors so it will not distract attention. Also, bonsai wire is usually single strand conductor because it is stiffer and will retain its shape better than multistrand. . Generally, wire is wire. For your purposes Grasshopper, find some house wire at the local home center..

Send your message to us

Galvanized Razor Barbed Wire Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches