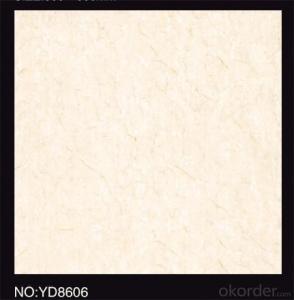

Full Polished Glazed Porcelain Tile 600 YDL6BB248

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1267.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

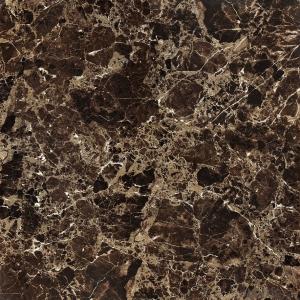

You Might Also Like

Product Brief Introduction

Full Polished Glazed Porcelain Tile 600 YDL6BB248 is one of the most popular color of Full Polished Serie, which is one serie of Polished Porcelain Tile in the present market. Just like other series, it could be used for interior floor for apartment, villa, super market as well as other public areas, due to its being high glossy and clean, homogeneous color shade as well as the reasonable price compared with natural stones.

Product Features

1) Available in many designs, specifications and assorted color,unique designs and exclusive quality

2) Used for indoor & outdoor wall and floordecorations, as well as Stair Case Product;

3) Easy to install, anti-dust, washable, acid-proof,alkali-proof, durable

4) Material: glazed porcelain

5) Customized sizes available according to clients’ requirements

6) Available dimensions

Material | Porcelain |

Dimension | 600x600 mm |

Packing | Carton + Wooden Pallets |

Finish | Glossy, over 90 degree. |

Usage | Floor and wall |

The polished porcelain tile is widely used for interior houseflooring, hotel lobby flooring, shopping mall as well as other public sites.

Vivid stone texture and vein bring our decoration the naturalstone beauty with much lower cost, easier quality control and easier decorationproceeding.

Advanced glazing technology to make sure the tile surface beautyvivid and clean, via ink-jetting or silk printing.

We could go with OEM model, making 2nd productionbased on client’s requirement;

We could offer flexible service on shipment and better supporton payment term;

Our quality guarantee is based on the strict productionprocedure, quality controlling on the shade, straightness as well as whitedegree.

Product Specification

Tile Type: Polished Porcelain Tile

Quality standard: GB/T4100-2006, ISO13006, ISO9001

Water Absorption Rate: 《0.5%

Breaking Strength: 》 1800 N

Rupture Modulus: 》40 MPa

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.15%

Edge Straightness: ±0.15%

Wearing Strength: 《1600 mm3

Glossiness: 》 85 Degree

Resistance to Chemical: Class UA

Resistance to Staining: Class 3.

Packing Information (For 27.5 Tons heavy 20’Fcl)

For 600x600mm, 4pcs/Ctn, 40 Ctns/Pallet, 960 Ctns/20’Fcl, 1382.4m2/20’Fcl

For 800x800mm, 3pcs/Ctn, 28 Ctns/Pallet, 616 Ctns/20’Fcl, 1182.72m2/20’Fcl

Production Line & Package

FAQ

1. For Polished Porcelain Tile, is the 30*60 available?

—— Yes, 30*60 is available. Due to the basic size is 60*60, we need to cut 60*60 tile into 30*60. 6 pcs are packed into one carton.

2. What is the MOQ for this tile?

—— Normally the MOQ is 1382.4 m2 for one 20’ container. To support our clients, we could go with 3 models to fill one container at most.

3. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton or our Carton with our CMAX brand name. But for carton of client’s own design, the MOQ for one size is 5 containers, due to the carton factory can’t arrange production if quantity is below 5000 pcs.

- Q: My kitchen floor tile has a number dings or chips caused by something heavy falling on them. Is there a way to repair these without having to remove/replace the entire tile?

- Sorry to hear that.. Any tile will top chip inexpensive or not.. Just some more easy than others.. This depends on the type of tile..I ve always had people touch them up w/ an enamel touch up that you repair appliances with.. This will depend on colors of course .. Finger nail polish is a tougher touch up product to help too.. Not a cure or a fix but a hide.. Should you get more tile in the future and want to avoid this get a pure porcelain were color go all the way thru and not a porcelain bodied tile there is a difference GL

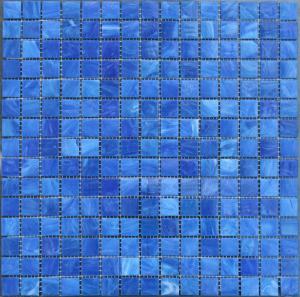

- Q: on this link.. uld someone please tell me what color glass tile is on the first and the second photos of the bathrooms?the top bathroom looks more like a pink base and the second bathroom has the dark gray tiles and the purple walls. also, what kind of walls are these? it looks different than just regular paint. i need a link to the tiles that both of these bathrooms have. i think the first one is more of a pink base and the second is more of a silver base.

- Are these beads seed beads? Really beautiful

- Q: What is the best brand of domestic tiles?

- Domestic tiles brand is better Douglas tiles Marco Polo tiles Dongpeng tiles Nobel tiles are all first-line brand tiles, service and quality are guaranteed!

- Q: I am going to be removing ceramic tile in my kitchen and was wondering what the easiest way to go about it was? I was going to use a hammer and a flat ended screw driver, what do you think?

- Dusty okorder

- Q: My kitchen has ceramic tile already installed and I despise it and have for years. I do not want to put a big investment into this house as I do not plan on living there for much over 2 more years. I just want to cover it up and make it look better. This site seems pretty legit and only deals with self stick tile. Anyone know of pros or cons? Have any suggestions?

- Cons would be that it costs close to $10 a square foot. I also doubt that it looks as good in person as the site claims. I've installed a lot of surface coverings, including tile-textured vinyl wallpaper and a variety of peel and stick material and they rarely look that convincing when they are right under your nose, as a countertop backsplash would be. That's a lot of money for a coverup job, And you don't say where the tile is installed. Walls? Countertop? Floors? That stickandgo is strictly for walls, not any area that would have moisture lying on it or traffic. If it is just your walls it would be a lot cheaper just to hire someone to tear off the ceramic tile and put up something different. It only cost me $6 a square foot for labor and $3 for material to have a real ceramic subway tile back splash installed in my kitchen last year. It would be even less if you did it yourself. If you are thinking of covering a floor, look at the Trafficmaster Allure material at Home Depot -- excellent product and about $2 a square foot. Installs like a dream, completely waterproof, can go over an uneven surface, adheres to itself, not what is behind it (it floats), easy to remove later, and both the tile and wood versions look and feel absolutely real. We did my friend's large bathroom with it in less than 4 hours last winter and it looks like a hardwood floor and holds up to anything. I used the slate-look tiles in my breakfast room of my previous house and everyone who saw it thought it was real stone. If it's your countertops, it is easy and cheap to replace countertops with new laminate and the new laminates are not your Grandma's formica -- many look like high-end granite and even metals.

- Q: I bought 12 x 12 ceramic tile from Lowe‘s branded as SURFACE SOURCE with a PEI rating 4. I bought each tile for $0.58 each. I want to use the tile for the kitchen, bathrooms, laundry room and living room. The tile was made in Mexico. I think the tile was being discontinued at Lowe‘s. Thus, I think that is why the price was so low. Did I make a mistake? The tile looks good and feels good so I do not see a problem with. I need an honest opinion.

- It will not wear as long as more durable higher priced tile, but it will last for many, many years. By the time it needs replaced again you'll probably have moved or want to replace it anyway. So, no, I don't think that you made a mistake if it is installed correctly.

- Q: How do you tile anyway? thank you

- Its much better too remove the old tile, tile requires a special backing board that the mortar adheres to, you would have to put it over the exisitng tile and it would bring your surfaces out another 1/2-1 or so. I would go to Home Depot or book store and buy a book on DIY tile. You will need to rent a wet saw to cut the tiles. You use mortar to adhere the tile, little plastic spacers in between the tile, then you finish off with grout. If you have never laid tile, I would try find a friend/family member who has, or get an estimate from a professional. It is a very labor intensive job, and you need to be meticulous. If anything is off you can get water problems cause cracking, mold, mildew, etc.

- Q: The logistics of maintaining my marble tile should be an important consideration when choosing what kind of tile I wish to install. Acidic cleaners can etch the tile, which will then need to be repaired, so watch out for them.How can I Maintain my tile and keep it clean with the proper solutions once it is installed?

- you need to remove the old grout on the surface and re apply new grout to fix the problem, you can even get grout that is tinted to the colour that you like .

- Q: How the gold fritters tiles

- on the quality of tiles, but also concerned about the sale of goods, such as delivery To teach you some simple identification of brick quality is good or bad way: 1. to see the origin (the general quality of Guangdong brick better); 2 to see flatness; 3 to see if there are pores, particles; The earth tiles 30 to 40 pounds, the heavier the weight of the brick the greater the degree of porcelain, the higher the quality of the higher the quality of the theory is better); 5. listen to sound; 6 to see the water absorption (all ceramic tiles should not absorb the back of the water); Test slip resistance (in the case of water)

- Q: can you tile an old brick fireplacegt;?would it look stupid?

- To do that it is a bit more complicated than it sounds. You would need to make the brick surface smooth, no crevaces. It's expensive time consuming. Consider resurfacing the fireplace

Send your message to us

Full Polished Glazed Porcelain Tile 600 YDL6BB248

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1267.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches