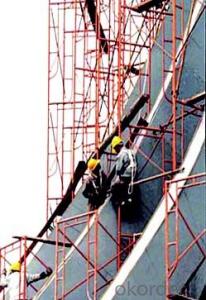

Frame Scaffolding Formwork Thickness of Scaffolding Pipe Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Frame Scaffolding Formwork Thickness of Scaffolding Pipe Made in China

Plastic Formwork Concrete Formwork Scaffolding Manufacturer Scaffolding Spanners with New Design

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Frame Scaffolding Formwork Thickness of Scaffolding Pipe Made in China

Frame Scaffolding Formwork Thickness of Scaffolding Pipe Made in China

Frame Scaffolding Formwork Thickness of Scaffolding Pipe Made in China

Frame Scaffolding Formwork Thickness of Scaffolding Pipe Made in China

- Q: Does steel frame formwork require any specific surface preparation?

- Yes, steel frame formwork generally requires surface preparation before use. This involves removing any dirt, rust, or debris from the surface of the steel frame to ensure proper adhesion and prevent any potential issues during the concrete pouring process.

- Q: Can steel frame formwork be used for both temporary and permanent column construction?

- No, steel frame formwork is typically used for temporary column construction as it can be easily assembled and dismantled. For permanent column construction, other materials like reinforced concrete are commonly used.

- Q: What are the common sizes of steel frame formwork panels?

- The common sizes of steel frame formwork panels vary depending on the specific construction project and the requirements of the concrete structure being built. However, there are a few standard sizes that are commonly used in the industry. One of the most common sizes for steel frame formwork panels is 1.2 meters by 2.4 meters (4 feet by 8 feet). This size is widely used and readily available, making it a popular choice for many construction projects. These panels are typically lightweight and easy to handle, making them suitable for a wide range of applications. Another common size for steel frame formwork panels is 1.5 meters by 3 meters (5 feet by 10 feet). These larger panels are often used for bigger concrete structures or projects that require a larger surface area to be covered. Despite their larger size, these panels are still relatively easy to handle and install. In addition to these standard sizes, custom sizes of steel frame formwork panels can also be manufactured to meet the specific needs of a construction project. This allows for greater flexibility and adaptability, ensuring that the formwork system can be tailored to the unique requirements of the concrete structure being built. It is important to note that the sizes mentioned above are just some of the common options available for steel frame formwork panels. The actual sizes used in a construction project will depend on various factors such as the design and dimensions of the concrete structure, the available space on the construction site, and the preferences of the construction team.

- Q: What are the different types of formwork bracing used with steel frame formwork?

- There are several different types of formwork bracing that can be used with steel frame formwork. These bracing systems are designed to provide support and stability to the formwork during the concrete pouring process. 1. Adjustable Steel Props: Adjustable steel props are commonly used as vertical bracing elements. They consist of a steel tube with a threaded end and a base plate. The props can be adjusted to different heights and are secured in place using locking pins. 2. Horizontal Steel Bracing: Horizontal steel bracing is used to provide lateral stability to the formwork. This type of bracing consists of steel tubes that are connected to the vertical props and secured using clamps or couplers. The bracing is typically installed at regular intervals along the length of the formwork. 3. Diagonal Bracing: Diagonal bracing is used to provide diagonal support to the formwork. This type of bracing is made up of steel tubes that are connected to the vertical props and secured using clamps or couplers. Diagonal bracing is typically installed at different angles to provide maximum stability. 4. Tie Rods: Tie rods are used to provide additional strength and stability to the formwork. They consist of steel rods that are threaded at both ends and are used to connect the formwork panels together. The tie rods are tightened using nuts and washers to hold the formwork in place. 5. Cross Bracing: Cross bracing is used to provide additional lateral stability to the formwork. This type of bracing consists of steel tubes that are connected diagonally between the vertical props. Cross bracing is typically installed at regular intervals to prevent any shifting or movement of the formwork. Overall, the different types of formwork bracing used with steel frame formwork are designed to provide support, stability, and strength to the formwork system during the concrete pouring process. These bracing systems ensure that the formwork remains in place and can withstand the pressure exerted by the concrete.

- Q: How is a steel frame formwork system assembled and disassembled?

- A steel frame formwork system is assembled by connecting prefabricated steel frames together in the desired configuration. The frames are then secured in place using clamps or pins. Once the concrete is poured and set, the system is disassembled by removing the clamps or pins and dismantling the steel frames, allowing for easy removal of the formwork.

- Q: Can steel frame formwork be used in projects with limited construction site supervision or management?

- Steel frame formwork is a versatile and durable solution for creating concrete structures, making it suitable for projects with limited construction site supervision or management. Its robustness allows it to withstand heavy loads and extreme weather conditions, ensuring stability even without constant supervision. Moreover, the ease of assembly and disassembly of steel frame formwork facilitates quick installation and removal, reducing the need for skilled labor and speeding up the construction process. Additionally, its adjustability and customization capabilities enable construction teams to modify the formwork system without extensive supervision or guidance. Furthermore, the high reusability of steel frame formwork minimizes the need for constant supervision or management in terms of material procurement. This means that even with limited supervision on-site, the formwork system can be reused multiple times. However, it is important to note that proper installation and usage of steel frame formwork still require some level of expertise and knowledge. Therefore, it is advisable to have at least some level of supervision or management to ensure correct implementation. In conclusion, steel frame formwork is a suitable option for projects with limited construction site supervision or management. Its durability, ease of assembly, flexibility, and reusability make it a reliable choice. However, it is crucial to ensure that there is still some level of expertise or guidance to ensure proper installation and usage.

- Q: Are there any limitations on the size and shape of structures that can be constructed using steel frame formwork?

- Steel frame formwork imposes restrictions on the size and shape of structures that can be built. The main limitation is the strength and stability of the steel frame itself. Although steel is renowned for its strength and durability, it has a maximum load capacity. Consequently, engineers and architects must evaluate the weight and distribution of the load during the design process to ensure it does not surpass the steel frame formwork's capacity. Furthermore, the form and intricacy of the structure can also present limitations. Steel frame formwork primarily employs standardized panels and components to construct the desired shape. Consequently, structures with complex curves or unconventional shapes may pose challenges when using steel frame formwork. In such situations, alternative formwork systems like custom-made wooden or flexible formwork may be more suitable. Additionally, the size of the structure can impact the viability of employing steel frame formwork. Larger structures may require additional reinforcement and support to maintain stability and prevent deformation. These supplementary measures can augment the complexity and cost of construction. To summarize, while steel frame formwork is a versatile and extensively used construction method, there are limitations on the size and shape of structures that can be built using this technique. Engineers and architects must carefully consider load capacity and shape intricacy when deciding between steel frame formwork and alternative formwork systems.

- Q: How does steel frame formwork differ from other types of formwork?

- Steel frame formwork differs from other types of formwork in that it is made up of steel panels and frames, providing higher strength and durability compared to traditional timber or plywood formwork. It offers greater resistance to bending and deformation, allowing for larger concrete pours and higher concrete pressures. Additionally, steel frame formwork can be easily assembled, adjusted, and reused, resulting in cost savings and increased efficiency in construction projects.

- Q: How does steel frame formwork contribute to the overall durability of a structure?

- Steel frame formwork contributes to the overall durability of a structure by providing a strong and rigid framework that supports the weight of the concrete during construction. This ensures that the structure is built with precision and accuracy, minimizing any potential for structural weaknesses or defects. Additionally, the steel frame formwork is highly resistant to warping, bending, and corrosion, which helps maintain the integrity and longevity of the structure over time.

- Q: What are the different types of formwork joints used with steel frame formwork?

- There are several types of formwork joints that can be used with steel frame formwork. These joints are designed to ensure the stability and strength of the formwork system during the concrete pouring process. Some of the different types of formwork joints commonly used with steel frame formwork include: 1. Butt Joint: This is the simplest form of joint where two formwork panels are joined together end to end. It is typically used for straight walls or columns. 2. Corner Joint: This joint is used to connect two formwork panels at a corner. It provides stability and helps maintain the desired shape of the structure. 3. T-Joint: As the name suggests, this joint forms a T-shape where three formwork panels meet. It is commonly used for connecting walls that intersect at right angles. 4. L-Joint: Similar to the T-joint, the L-joint is used to connect two formwork panels at a 90-degree angle, forming an L-shape. It is typically used for forming walls or columns. 5. Y-Joint: This joint is used for forming walls or columns that branch out, creating a Y-shape. It provides stability and ensures that the concrete is properly contained. 6. Slip Joint: A slip joint is used to allow for movement between formwork panels. It is typically used in situations where thermal expansion or contraction may occur. 7. Key Joint: This joint is used to create a keyway in the concrete, which helps to transfer loads between adjacent pours. It is commonly used in large-scale projects where multiple pours are required. Each of these formwork joints serves a specific purpose and is used based on the requirements of the structure being constructed. The proper installation and use of these joints are crucial for ensuring the stability and integrity of the formwork system and the resulting concrete structure.

Send your message to us

Frame Scaffolding Formwork Thickness of Scaffolding Pipe Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords