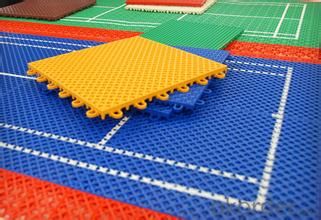

football field artificial floor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100吨 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Category athletics track

Num sk-304A Material PP Applications football field

Blocky shape

The number of cartons 100

Specifications 304 * 304 * 13,250 * 250 * 13

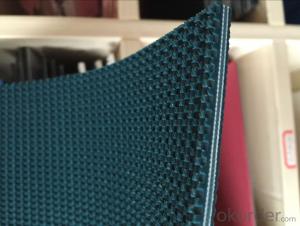

Fast assembly sports flooring, also known as suspension assembly floor, is one currently on the market is becoming a popular fourth-generation sports flooring.

1974 originated in the United States, 2002 to enter China. The main use of modified PP (polypropylene) as raw material, by the belt buckle monolithic floor lap assembled together as a movement of the use of the floor. It uses floating structure design with enhanced support legs sturdy structure, create superior vertical damping effect, non-slip surface can effectively prevent sports injuries. Environmentally friendly, durable, convenient, portable, cold thermal aging, comfort, safety and health, sports performance and other characteristics, sub leisure and sport, is a new environmental health sports flooring, widely used in the United States and Europe currently more than 100 countries around the world more than one hundred thousand sites using this floor, has 30 years of cooperation with the NBA, currently used in a variety of sports venues and domestic kindergarten elementary school playground and sports venues, and gradually developed into a stadium renovation and new laying and nursery sports venues of choice timber.

Yiwu Excellencies fast assembly characteristics and advantages of the floor

First, the environmental protection:

Yiwu Excellencies quickly assembled sports flooring mainly modified polypropylene (PP) as the main raw material, non-toxic, tasteless, non-parasitic bacteria, green, without using any adhesive, installation personnel during construction no longer tolerate those who harm the human body binder odor. Polypropylene recyclable materials, such as plastic pots can be manufactured, plastic buckets and other supplies.

Second, healthy comfort:

Achieve a good vertical shock absorption and energy return delivery, provide lateral buffer function, anti-sprain, ankle injuries and other sports injuries, spinal movement effectively protect the health, and ensure the healthy growth of young bones; latest wear layer design, so always bear sole the ground, non-slip and can deliver a strong movement arbitrary power. Floor surface special treatment, with the light levels, non-reflective glare, to better protect athletes eye, easy to produce fatigue. Low heat reflection, moisture-free, no odor retention;

- Q: Do olive nets affect the ripening process of olives?

- Yes, olive nets can affect the ripening process of olives. The nets provide shade and protection to the olives, which can slow down the ripening process by reducing direct exposure to sunlight and air circulation. This can result in slower color change, softer texture, and delayed maturation. However, nets also shield the olives from birds and pests, preventing damage and ensuring a higher yield. Therefore, the impact of olive nets on ripening depends on the specific goals and priorities of the olive grower.

- Q: Can olive nets be used for olive tree root protection?

- Yes, olive nets can be used for olive tree root protection. Olive nets are often used to cover the soil around the base of olive trees to prevent erosion, weed growth, and to retain moisture in the soil. This can help protect the roots of olive trees and promote their healthy growth.

- Q: Can olive nets be used for both mechanical and hand harvesting?

- Yes, olive nets can be used for both mechanical and hand harvesting.

- Q: Do olive nets affect the growth of beneficial flora and fauna?

- Yes, olive nets can have an impact on the growth of beneficial flora and fauna. The nets provide a physical barrier that can limit access to sunlight, moisture, and airflow, affecting the overall ecosystem dynamics. Additionally, they may disrupt pollination processes and alter the nutrient cycling within the soil. However, the extent of this impact can vary depending on the netting material, duration of use, management practices, and specific characteristics of the local environment.

- Q: Can olive nets be used in combination with tree spacing techniques?

- Yes, olive nets can be used in combination with tree spacing techniques. Olive nets are commonly used to protect olive trees from bird damage and to collect fallen olives during harvesting. By utilizing tree spacing techniques, such as planting trees at specific distances apart, it is possible to optimize the use of olive nets and ensure effective coverage and protection for the entire olive orchard.

- Q: Can olive nets be used for both traditional and modern irrigation methods?

- Yes, olive nets can be used for both traditional and modern irrigation methods. Olive nets are versatile and can be adapted to different irrigation techniques such as drip irrigation, sprinkler irrigation, or even flood irrigation. They can help distribute water evenly across the olive trees, preventing water wastage and promoting efficient water usage. Additionally, olive nets can also protect the soil from erosion and conserve moisture, which is beneficial for both traditional and modern irrigation approaches.

- Q: How do you prevent olive nets from sagging or drooping?

- One effective way to prevent olive nets from sagging or drooping is by properly tensioning them. This can be achieved by ensuring that the nets are securely fastened and tightened around the trees or posts they are attached to. Additionally, using supporting structures such as poles or stakes at regular intervals can help maintain the desired tension and prevent sagging. Regular inspection and adjustment of the nets may also be necessary to ensure they stay taut and in place throughout the harvesting season.

- Q: Can olive nets be used in both irrigated and non-irrigated olive farms?

- Yes, olive nets can be used in both irrigated and non-irrigated olive farms. Olive nets are primarily used to collect the fallen olives during harvest, regardless of the irrigation system used in the farm.

- Q: How do olive nets help in reducing the risk of nutrient leaching?

- Olive nets help in reducing the risk of nutrient leaching by acting as a physical barrier that prevents excessive rainfall or irrigation water from carrying away valuable nutrients from the soil. The nets trap the water and allow it to slowly percolate into the ground, allowing the roots to absorb the necessary nutrients while minimizing their loss through leaching.

- Q: How do I see if the plastic cup is qualified?

- They attach triangular recovery marks to plastic products and use figures 1 to 7 and English abbreviations to refer to the type of resin used in plastics.

Send your message to us

football field artificial floor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100吨 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords