Food Grade PVC Flat Belting Conveyor/Potato Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Food Processing Conveyor Belt

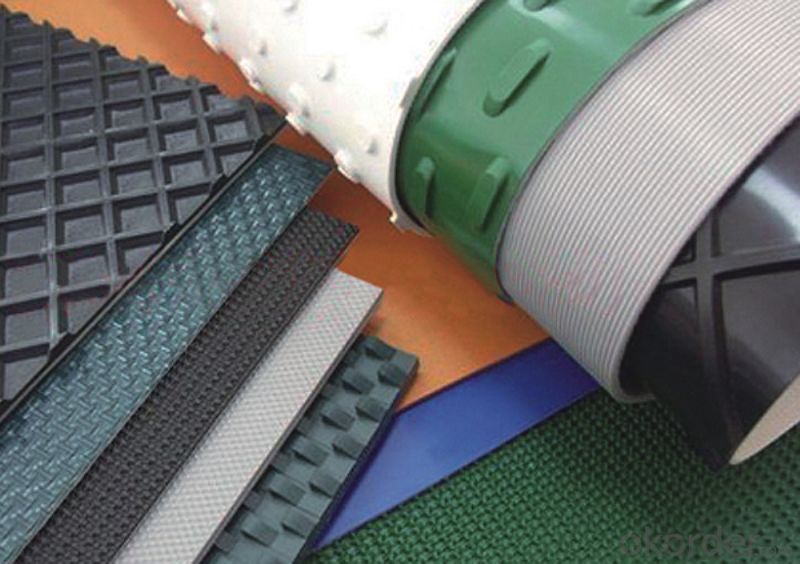

Food Processing Conveyor Belt Introduction

Food processing conveyor belt choose high quality high strength polyester fabric are the core, coated with PU or PVC as loading surface. With advantages of good flexibility, material environmental friendly, light duty, high tensile strength, anti oil, easy learning, our food processing conveyor belt meet EU and USA market requirements.

Food Processing Conveyor Belt Application

Food processing conveyor belt is widely used in food industry, such as vegetables, snack food, beer, sea food, etc.

Food Processing Conveyor Belt Advantage

Food processing conveyor belt is made of harmless material, no toxicity, no smell, anti-oil, easy cleaning, high tensile strength, good flexibility, light weight, solid and durable.

Food Processing Conveyor Belt Specifications

Total thickness(mm) 0.8~5.0 | Top coating hardness( Shore A) 55~92 |

Total weight(kg/m2) 0.9~5.4 | Belt tension 1% elongation(N/mm) 5~ 30 |

Minimum production width(mm) 15~180 | Working temperature range(℃) -20/+90 |

Type of support R=expansion cylinder, S=flat, T=groove shape | Max production width(mm) 3000 |

Lateral stability Yes | Food grade Yes |

Low noise | Fire resistance |

Surface antis tatic |

Food Processing Conveyor Belt Photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

Quality is the first priority, we have strict quality control system.

1) All raw material we used are environmental freindly

2) Quality Control Department specially responsible for quality checking in each process. We make testing on incoming raw material and finished products. Your third party testing is also welcomed.

3) Skillful workers care every details in handling the producing and packing processes.

Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: Why should I granulate before injection? What's the advantage of granulation?

- The purpose of granulation is to consider from the quality, complete use of broken material injection molding can be completely. Some products, however, have problems with injection molding of fully cracked materials and have to use granulation materials.

- Q: How do you dye plastics?

- Dry staining dye and a certain proportion of plastic pellets into the rotating drum, and adding 0.01%~0.1% zinc stearate or white mineral oil as a wetting agent to make plastic and easy to dye binding, rotating drum to make plastics and dye mixing.

- Q: Can olive nets damage the olive trees?

- Yes, olive nets can potentially damage olive trees if they are not properly installed or maintained. If the nets are too tight or rub against the branches, they can cause abrasions or breakages. Additionally, if the nets are left on for an extended period, they can hinder air circulation, leading to moisture buildup and increased risk of diseases. Therefore, it is crucial to use olive nets correctly and regularly inspect them to prevent any damage to the olive trees.

- Q: Can plastics be recycled?

- Become soft when heated so as to flow and become hardened by cooling. The process is reversible and can be repeated. Polyethylene, polypropylene, PVC, polystyrene, POM, polycarbonate, etc.. Thermoplastics can be recycled, while thermosetting plastics cannot be recycled.

- Q: What is the average cost of an olive net?

- The average cost of an olive net can vary depending on various factors such as size, material, and quality. It is recommended to research and compare prices from different suppliers to get an accurate estimate.

- Q: How do you understand the level of engineering plastics?

- HDPE (HDPE): common white bottles, cleaning products, bath products. High temperature resistant, but not easy to clean, easy to breed bacteria, do not recycle.

- Q: How do you dispose of an old or damaged olive net?

- To dispose of an old or damaged olive net, it is recommended to check with your local waste management facility or recycling center for specific instructions. In some cases, these nets can be recycled as plastic or disposed of as non-recyclable waste. It is important to follow proper disposal methods to minimize environmental impact and promote sustainability.

- Q: Can olive nets be repaired if they become damaged?

- Yes, olive nets can be repaired if they become damaged. The repair process typically involves mending tears or replacing damaged sections of the net to ensure its effectiveness in harvesting olives.

- Q: Can olive nets be used for other fruit trees as well?

- Yes, olive nets can also be used for other fruit trees. Olive nets are commonly used to protect olive trees from birds and other animals that may damage the fruit. However, they can also be used for other fruit trees to serve the same purpose of preventing birds and animals from accessing and damaging the fruit.

- Q: How do olive nets prevent damage from strong sunlight?

- Olive nets prevent damage from strong sunlight by providing shade and reducing the direct exposure of the olive trees to the intense rays of the sun. This helps to regulate the temperature and moisture levels around the trees, minimizing the risk of sunburn and dehydration. Additionally, the nets act as a barrier, blocking harmful ultraviolet (UV) rays that can cause damage to the leaves and fruits.

Send your message to us

Food Grade PVC Flat Belting Conveyor/Potato Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords