Insulating Fire Bricks | Refractory Bricks Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 800 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Brick

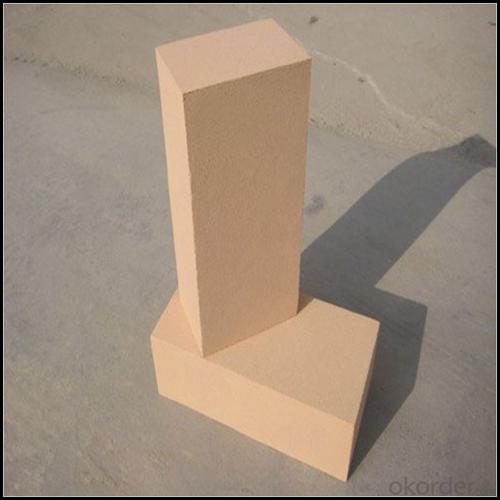

CMAX firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay by mixing, press-forming, drying, sintering and machining. Bricks contain carefully-graded organic fillers which are burned out during sintering to give a uniform controllable pore structure. This technique makes product feature low thermal conductivity and excellent heat insulation

Features

1. The dimensions are more exactly.

2. Low iron content and impurities

3. Good thermal stability;

4. High refractoriness,

5. anti alkaline /acid erosions,

6. Mechanical and chemical properties are very good.

7. Strong thermal shock resistance.

Application

1.Carbon bake furnaces in the aluminium industry

2.Preheat zones and cyclones of rotary cement kilns

3.Insulation for glass tanks

4.Coke ovens

5.Blast furnaces

6.Reheating furnaces

7.Suspended roofs

8.Lime kilns

9.chimney

Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Timely response to your inquiry, multiple choice recommendations based on your demand,quickly respond mails and provide solutions.

Sample and trial order are accepted for the quality evaluation

Arrange production on time and control quality strictly.

Book the earliest vessel or plane to guarantee the delivery time.

Provide all the detailed news and pictures from order to delivery;

Offer relative export documents and original certificate if needed;

Warm and considerable after-sale service

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: What is the typical modulus of rupture of an insulating fire brick?

- The modulus of rupture of an insulating fire brick can differ based on the brick's particular composition and manufacturing method. On average, insulating fire bricks usually have a modulus of rupture ranging from 1 to 10 megapascals (MPa). This indicates that these bricks can endure a bending force or pressure of 1 to 10 MPa before they fracture or break. It should be emphasized that the modulus of rupture can be affected by factors like the density, porosity, and chemical composition of the insulating fire brick.

- Q: Are insulating fire bricks suitable for use in thermal shock applications?

- Insulating fire bricks prove to be appropriate for thermal shock applications. Specifically designed to endure sudden temperature variations without any cracks or breaks, they possess a low thermal conductivity and a high thermal resistance, making them an optimal choice for concerns related to thermal shock. Comprised of lightweight refractory materials, these bricks often contain a significant amount of alumina or silica, which grants them exceptional thermal stability and resistance to thermal shock. Their utilization can be seen in a wide range of high-temperature scenarios, including kilns, furnaces, and fireplaces, where they face extreme temperature fluctuations. Ultimately, insulating fire bricks demonstrate their suitability for thermal shock applications by effectively enduring abrupt temperature changes and maintaining their structural integrity.

- Q: Are insulating fire bricks suitable for applications requiring low thermal conductivity?

- Yes, insulating fire bricks are suitable for applications requiring low thermal conductivity. These bricks are designed to have excellent insulation properties, allowing them to effectively minimize heat transfer and maintain low thermal conductivity. They are commonly used in industries such as metallurgy, ceramics, and glass manufacturing, where thermal insulation is crucial for efficient and controlled processes.

- Q: Are insulating fire bricks suitable for use in high-temperature chimneys?

- Indeed, high-temperature chimneys can indeed benefit from the utilization of insulating fire bricks. These bricks are purposefully crafted to endure drastic temperatures and offer superb insulation characteristics. With their elevated melting point and reduced thermal conductivity, they possess the ability to proficiently retain heat and obstruct its escape through the chimney walls. Consequently, this aids in maintaining a desirable temperature within the chimney, a pivotal factor for optimal combustion and efficient chimney operation. Furthermore, insulating fire bricks possess the advantageous qualities of being lightweight and long-lasting, rendering them an impeccable selection for constructing chimneys that are subjected to elevated temperatures.

- Q: Do insulating fire bricks have a high insulating capacity?

- Insulating fire bricks possess a remarkable capacity for insulation. Crafted with utmost precision, these bricks exhibit exceptional thermal insulation characteristics, rendering them exceptionally proficient in obstructing heat transfer. Their composition entails lightweight materials like ceramic fibers, known for their minimal thermal conductivity. Consequently, insulating fire bricks adeptly capture and maintain heat, effectively thwarting its escape and ensuring adequate insulation of the surrounding space. Owing to their superior insulating capacity, these bricks find extensive utilization in domains that prioritize heat retention and energy efficacy, including furnaces, kilns, and fireplaces.

- Q: What is the cost of insulating fire bricks?

- The price range for insulating fire bricks can differ depending on several factors, including the required quantity, brick quality, and supplier. Typically, these bricks can cost anywhere between $2 and $5 per brick. Nevertheless, the price may increase for specialized bricks with unique attributes like enhanced insulation or greater durability. To guarantee the best value for money, it is advisable to obtain quotes from multiple suppliers and compare prices.

- Q: Can insulating fire bricks be used in the construction of metal smelting molds?

- Yes, insulating fire bricks can be used in the construction of metal smelting molds. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for use in metal smelting molds where heat retention is crucial.

- Q: What is the water absorption of insulating fire bricks?

- Insulating fire bricks possess the capacity to absorb water when submerged or in contact with it. This characteristic holds significance when employing these bricks in situations involving exposure to moisture or water. Typically, insulating fire bricks exhibit a low water absorption rate, varying between 2% and 8% depending on their specific type and composition. The bricks' dense and compact structure restricts the infiltration and absorption of water molecules, thus accounting for this low water absorption. The advantage of insulating fire bricks' low water absorption manifests in various applications. Firstly, it prevents moisture from permeating the bricks and causing damage or deterioration. Secondly, it ensures that the bricks do not retain excessive moisture, which could lead to increased weight, diminished insulation properties, or even the formation of cracks or fractures when subjected to high temperatures. Due to their low water absorption, insulating fire bricks manage to retain their structural integrity and insulation performance even in wet or humid environments. This quality makes them suitable for deployment across a diverse range of industries and applications, including kilns, furnaces, ovens, and other high-temperature processes that necessitate resistance to moisture. In summary, the water absorption of insulating fire bricks constitutes a vital characteristic that contributes to their durability, thermal insulation properties, and ability to withstand moisture-related challenges.

- Q: What material is good for indoor thermal insulation?

- Now the main building to do insulation, and generally use benzene board, we do indoor heat preservation is generally used, glass cotton is glass fiber, contact the skin after particularly uncomfortable

- Q: Can insulating fire bricks be used in the construction of steam boilers?

- Insulating fire bricks are ideal for use in steam boiler construction. They are crafted from lightweight refractory materials that offer outstanding thermal insulation capabilities. These bricks are specifically designed to endure high temperatures and provide insulation in industries where heat retention is crucial, such as steam boiler construction. The advantage of using insulating fire bricks lies in their low thermal conductivity, which allows for effective heat loss reduction and enhanced energy efficiency in steam boilers. When these bricks are incorporated into the construction of steam boilers, the overall heat transfer efficiency increases, resulting in reduced fuel consumption and lower operating costs. In addition, insulating fire bricks possess exceptional resistance to thermal shock. This means they can withstand sudden temperature fluctuations without cracking or breaking. This quality is particularly significant in steam boiler applications, where the temperature can vary greatly during operation. To summarize, insulating fire bricks are an excellent choice for steam boiler construction due to their remarkable thermal insulation properties, low thermal conductivity, and resistance to thermal shock. They contribute to improved energy efficiency, decreased fuel consumption, and the long life of the boiler.

Send your message to us

Insulating Fire Bricks | Refractory Bricks Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 800 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords