Fin Tube Aluminum Coils - Alloy 3003 PVDF Aluminum Coil for Roofing/Ceiling/Gutter/Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

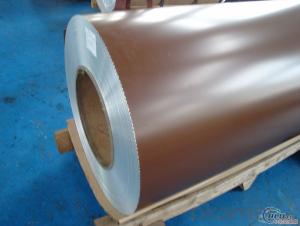

Alloy 3003 PVDF Aluminium Coil for Roofing/Ceiling/Gutter/Decoration

Specification

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.05~10mm |

Width | <1600mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~25micron(EN ISO-2360:1995) PVDF25 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

Packing

FAQ

Q: How can I request a product sample? A: The samples are free but freight should be collected. Please send sample list and courier account number by email.

Q: How can I request a product catalog? A: The hard copies of catalogs are free but freight should be collected. Please send courier account number by email. You are suggested to request a PDF catalog.

Q: Wha's your payment terms? A: One is T/T 30% before production and 70% against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q: What's your trade terms? A: FOB, CNF(CFR), CIF, EXW.

Q: How long is the quality guarantee? A: All of our products have a period of quality guarantee since time of shipment. Please contact your salesman for more details, as different products enjoy different time of guarantee

- Q: Is it possible to recycle aluminum coils in various countries around the world?

- <p>Yes, aluminum coils can be recycled in many countries around the world. Recycling aluminum is a global practice due to its high value and the energy savings associated with recycling compared to producing aluminum from raw materials. Different countries have their own recycling programs and facilities that handle aluminum waste, including coils. However, the specific regulations and processes for recycling aluminum coils can vary by country, and it's important to check local recycling guidelines to ensure proper disposal and recycling.</p>

- Q: Can aluminum coils be used in the production of automotive body panels?

- Yes, aluminum coils can be used in the production of automotive body panels. Aluminum is a lightweight and durable material that offers excellent corrosion resistance, making it ideal for automotive applications. The use of aluminum coils helps to reduce the weight of the vehicle, resulting in improved fuel efficiency and overall performance.

- Q: How do I deal with too much aluminum powder when the aluminum strips are divided?

- For example, the wind speed control did not meet the requirements, or not in accordance with the explosion-proof ventilation system requirements set, including pipeline setting, setting, filter series parallel is the selection of explosion-proof, whether Mars and extinguishing measures.

- Q: What is the role of aluminum coils in the construction of power plants?

- Aluminum coils are commonly used in power plants for the construction of heat exchangers and condensers. These coils play a crucial role in facilitating the transfer of heat and efficiently cooling fluids within the power plant system. The lightweight and corrosion-resistant nature of aluminum makes it an ideal material choice for these applications, ensuring optimal performance and longevity of the power plant equipment.

- Q: How do aluminum coils compare to brass coils in terms of corrosion resistance?

- In terms of corrosion resistance, aluminum coils generally outperform brass coils due to the presence of a natural oxide layer on aluminum's surface. This layer acts as a protective barrier, shielding the metal from moisture and other corrosive elements. On the other hand, brass coils, made from copper and zinc, are more vulnerable to oxidation and corrosion. Although brass coils may develop a protective patina over time, it is not as effective as the oxide layer found on aluminum coils. As a result, aluminum coils are commonly chosen for applications that require high corrosion resistance, such as in marine or coastal environments.

- Q: How do aluminum coils perform in cryogenic environments?

- Aluminum coils generally perform well in cryogenic environments due to their low thermal expansion coefficient and high thermal conductivity. When exposed to extremely low temperatures, aluminum coils exhibit minimal contraction and expansion, making them suitable for use in cryogenic applications. The low thermal expansion coefficient ensures that the coils maintain their structural integrity and do not deform or crack under extreme temperature fluctuations. Additionally, aluminum's high thermal conductivity allows for efficient heat transfer, enabling the coils to dissipate excess heat and maintain a stable temperature within the cryogenic environment. Overall, aluminum coils are a reliable choice for use in cryogenic environments and can effectively withstand the challenges posed by extremely low temperatures.

- Q: Can aluminum coils be used in high-humidity environments?

- Indeed, high-humidity environments can accommodate the use of aluminum coils. Due to its corrosion-resistant nature, aluminum proves to be a fitting material for areas with elevated humidity levels. The formation of a natural oxide layer on the aluminum surface acts as a safeguard against moisture, effectively warding off rust and corrosion. Hence, aluminum coils are widely favored for HVAC systems, as they encounter regular exposure to moisture and humidity. Moreover, the lightweight, durable, and exceptional heat transfer properties of aluminum coils render them an optimum selection for a multitude of industrial and commercial applications in high-humidity settings.

- Q: How do aluminum coils contribute to the electrical conductivity of products?

- Aluminum coils contribute to the electrical conductivity of products due to their excellent electrical conductivity property. When electrical current is passed through aluminum coils, they allow the flow of electrons with minimal resistance, enabling efficient transmission of electricity and enhancing the overall conductivity of the product.

- Q: What are the ideal materials for crafting a lampshade and why are they preferred?

- <p>The best material for making a lampshade depends on the desired aesthetic and functional requirements. Fabric is often preferred for its ability to diffuse light and provide a warm glow, with materials like cotton or linen being popular choices for their durability and texture. For a more modern look, materials like acrylic or glass can be used, offering a sleek appearance and the potential for more direct light. Paper is also a good option for its cost-effectiveness and the variety of textures and colors available. Ultimately, the best material is one that complements the lamp's design and the room's d茅cor while fulfilling the necessary light diffusion and safety requirements.</p>

- Q: Can aluminum coils be used for nameplates and labels?

- Indeed, nameplates and labels can utilize aluminum coils. Aluminum, being a versatile material, presents numerous benefits in this regard. Notably, its lightweight nature coupled with its durability renders it suitable for diverse applications. Furthermore, aluminum boasts exceptional resistance to corrosion, making it an excellent choice for outdoor usage or environments with high humidity levels. Moreover, aluminum lends itself easily to stamping, embossing, or engraving, thereby facilitating the creation of intricate designs and detailed text. Additionally, it is feasible to apply coatings or anodize aluminum coils to augment their visual appeal or provide added protection. All in all, aluminum coils offer a dependable and cost-efficient solution for nameplates and labels.

Send your message to us

Fin Tube Aluminum Coils - Alloy 3003 PVDF Aluminum Coil for Roofing/Ceiling/Gutter/Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords