Filament Geotextile in Dams Construction - Geotextile Malaysia

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

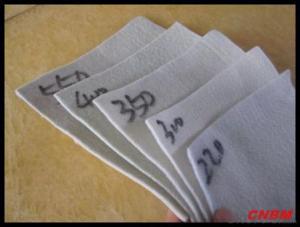

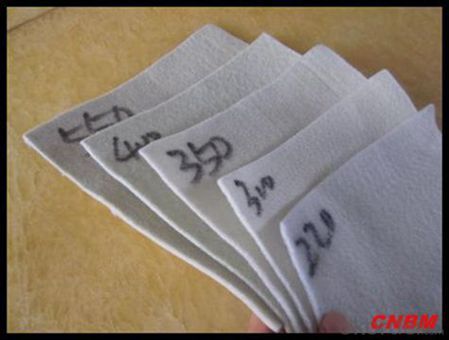

Specification

Advantage Pp Woven Geotextile For Railway Construction

1.High Strength

2.Low Elongation

3.Optimum Permeability Characteristics

Application Woven Polypropylene (Pp) Geotextile

1. Roadway Separation

2. Railroad Stabilization

3. Subsurface Drainage

4. Containment

5. Temporary Liners

Function

1. Isolation

2. protection

3. Filtration and drainage

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the key differences between woven and nonwoven geotextiles?

- The key differences between woven and nonwoven geotextiles lie in their manufacturing processes and physical properties. Woven geotextiles are created by interlacing individual yarns or fibers in a crisscross pattern, resulting in a stable and strong fabric. On the other hand, nonwoven geotextiles are manufactured by bonding or felting fibers together using mechanical, thermal, or chemical processes, resulting in a fabric with random fiber orientation. Woven geotextiles typically have higher tensile strength and puncture resistance due to their interlocked yarns, making them suitable for applications that require structural stability and load distribution. They are commonly used in road construction, erosion control, and soil stabilization projects. Nonwoven geotextiles, while generally having lower strength properties compared to their woven counterparts, offer advantages such as filtration, drainage, and separation functions. They are commonly used for filtration and separation in drainage systems, as well as in erosion control, landscape fabric, and geocomposite applications. Overall, the choice between woven and nonwoven geotextiles depends on the specific project requirements, such as load-bearing capacity, filtration needs, and budget considerations.

- Q: How do geotextiles help with sediment control in construction sites?

- Geotextiles are used in construction sites to help with sediment control by acting as a barrier that traps sediment and prevents it from being washed away by water runoff. These permeable fabrics allow water to pass through while retaining the sediment, reducing erosion and preventing pollution of nearby water bodies.

- Q: Can geotextiles be used in underground gas storage projects?

- Yes, geotextiles can be used in underground gas storage projects. Geotextiles are often used as a lining material in gas storage projects to provide separation, filtration, and reinforcement. They help to prevent the migration of soil particles, maintain the integrity of the storage structure, and ensure the overall stability of the project.

- Q: How do geotextiles affect soil erosion rates?

- Geotextiles can significantly reduce soil erosion rates by acting as a protective barrier. They prevent soil particles from being washed away by water or blown away by wind, while still allowing water to pass through. This helps to stabilize the soil, improve its structural integrity, and promote vegetation growth, ultimately leading to a reduction in erosion rates.

- Q: 200g geotextile how much money a square

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: How are geotextiles classified?

- Geotextiles are classified based on their manufacturing process, material composition, and intended application.

- Q: Cement concrete bridge is a film curing or geotextile maintenance

- Commodity concrete pouring is completed, should be in the slurry after grinding as soon as possible to cover and sprinkler conservation. Commodity concrete bridge deck with full coverage of sprinkler conservation methods, covering materials with two sticky one geotextile, every 1t sprinkler once, to ensure the quality of conservation, to prevent cracks.

- Q: How do geotextiles contribute to environmental sustainability?

- Geotextiles contribute to environmental sustainability by preventing soil erosion, improving water quality, promoting vegetation growth, and reducing the need for harmful chemicals and excessive water usage in agriculture.

- Q: Can geotextiles be used in retaining wall drainage systems?

- Yes, geotextiles can be used in retaining wall drainage systems. Geotextiles are commonly used as a filter to prevent soil erosion while allowing water to pass through. In retaining wall drainage systems, geotextiles can be installed behind the wall to prevent the clogging of drainage pipes and promote efficient water flow, reducing hydrostatic pressure and preventing damage to the wall.

- Q: What are the environmental considerations of geotextiles?

- Geotextiles have several environmental considerations, including their potential to release microplastics into the environment, their impact on soil and water quality, and their potential for improper disposal. Additionally, the production and manufacturing processes of geotextiles may contribute to carbon emissions and energy consumption, further affecting the environment. Therefore, proper usage, disposal, and monitoring of geotextiles are essential to minimize their environmental impact.

Send your message to us

Filament Geotextile in Dams Construction - Geotextile Malaysia

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords