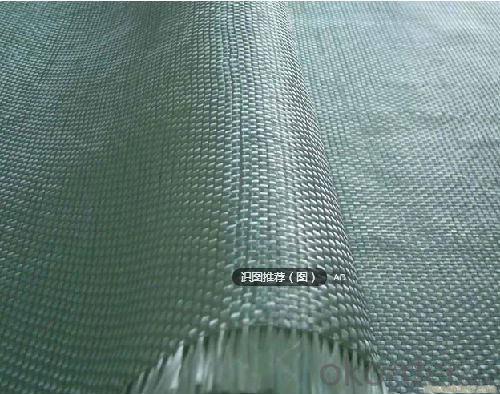

Fiberglass Roofing Fabric with Medium Silica Fiberglass Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction:

Medium silica fabrics can be used for a long period of time without changing their properties perat the temperature of 800℃ as it contains more than 70%±5% silica.

2.Properties

No asbestos orceramic,no harm to human

Low thermal conductivity,excellent thermal insulation

Superb electric insulation

Inert to majority of chemical reagents

Good flexibility

3.Application

Fire fighting

High temperature gas filtration

Thermal insulation

4.Specification

| Type | Weave Type | Area Weight | Width cm | Thickness | Warp Yarns/cm | Weft yarns/cm |

| RS-600 | Satin 8HS | 600±50 | 100 | 0.75±0.1 | 18±1 | 13±1 |

| RS-1100 | Satin 12HS | 1100±50 | 100 | 1.35±0.1 | 18±1 | 13±1 |

5.Package and Delivery Time.

Packed with carton and pallets.The products will be ready in 15-20 days after the order confirmation.

FAQ:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: Can fiberglass fabric be used for heat-resistant gloves?

- Yes, fiberglass fabric can be used for heat-resistant gloves. Fiberglass has excellent thermal resistance properties, making it suitable for applications that require protection against high temperatures.

- Q: Is fiberglass fabric suitable for use in aerospace composites?

- Yes, fiberglass fabric is suitable for use in aerospace composites. Fiberglass is a widely used material in the aerospace industry due to its excellent strength-to-weight ratio, durability, and resistance to corrosion. It offers high tensile strength and stiffness, making it ideal for applications that require structural integrity and load-bearing capabilities. Additionally, fiberglass fabric can be easily molded into complex shapes, allowing for the production of intricate aerospace components. Furthermore, fiberglass composites exhibit good thermal and electrical insulation properties, which are essential in aerospace applications where temperature fluctuations and electrical conductivity need to be controlled. Overall, fiberglass fabric is a reliable and proven material that has been successfully employed in the construction of various aerospace components, such as aircraft wings, fuselages, and interior panels.

- Q: How is fiberglass fabric used in the production of insulation papers?

- Fiberglass fabric is commonly used in the production of insulation papers due to its excellent thermal properties and durability. The fabric is usually made from fine strands of glass fibers that are woven together to form a strong and flexible material. In the production of insulation papers, fiberglass fabric is often used as a reinforcement layer. It is placed between layers of paper or other insulating materials to provide added strength and stability. The fabric helps to prevent tearing or ripping of the insulation papers, ensuring their longevity and effectiveness. Moreover, fiberglass fabric is also highly resistant to heat, making it an ideal choice for insulation applications. It can withstand high temperatures without melting or degrading, allowing it to effectively retain and reflect heat within the insulation system. This property is crucial in preventing heat loss or gain, leading to energy efficiency and cost savings. Furthermore, the use of fiberglass fabric in insulation papers enhances their fire resistance capabilities. Fiberglass is inherently non-combustible and does not contribute to the spread of flames. When incorporated into insulation papers, it acts as a barrier against fire, helping to contain and limit its spread. Overall, fiberglass fabric plays a vital role in the production of insulation papers by providing strength, thermal insulation, and fire resistance. Its use ensures that the insulation materials are durable, energy-efficient, and safe, making it a preferred choice in various industries such as construction, automotive, and aerospace.

- Q: Can fiberglass fabric be used for insulation sleeves?

- Yes, fiberglass fabric can be used for insulation sleeves. It has excellent thermal insulation properties, is fire-resistant, and can withstand high temperatures, making it an ideal choice for insulating sleeves.

- Q: What's the difference between double faced fiberglass clad laminate and double faced copper clad laminate?

- Epoxy paper substrate epoxy paper substrate is a paper based copper-clad laminate with epoxy resin as adhesive. It is slightly better than FR-l in electrical and mechanical properties. Its main product model is FR-3, and the market is mostly in europe.

- Q: What are the different finishes available for fiberglass fabric rolls?

- Some of the different finishes available for fiberglass fabric rolls include plain weave, leno weave, satin weave, twill weave, and herringbone weave. These finishes determine the pattern and texture of the fabric and can impact its strength, flexibility, and durability. Additionally, there are finishes that can be applied to fiberglass fabric rolls to enhance properties such as fire resistance, water repellency, and chemical resistance.

- Q: How does fiberglass fabric perform in terms of moisture absorption?

- Known for its exceptional resistance to moisture absorption, fiberglass fabric does not readily absorb water or moisture due to its non-porous and hydrophobic nature. This characteristic renders it highly suitable for situations where exposure to moisture or humidity is a concern. Moreover, the low moisture absorption of fiberglass fabric aids in preserving its structural integrity and dimensional stability, even in environments with elevated moisture levels. Consequently, fiberglass fabric's outstanding performance in terms of moisture absorption establishes it as a dependable choice across various industries and applications.

- Q: Is fiberglass fabric suitable for making tents and awnings?

- Yes, fiberglass fabric is suitable for making tents and awnings. Fiberglass fabric is known for its durability, strength, and resistance to various weather conditions, making it an excellent choice for outdoor applications like tents and awnings. It is lightweight, yet provides excellent protection from the elements such as rain and wind. Additionally, fiberglass fabric has good UV resistance, which helps to prevent fading and damage from prolonged exposure to the sun. Its inherent fire-resistance properties also make it a safe choice for outdoor structures. Overall, fiberglass fabric is a suitable material for making tents and awnings as it offers a combination of strength, durability, and weather resistance necessary for these applications.

- Q: How does fiberglass fabric perform in durability?

- Fiberglass fabric is highly renowned for its exceptional durability. Due to its composition of woven glass fibers, it possesses excellent strength and resistance to wear and tear. This fabric is not easily deformed or stretched, allowing it to maintain its shape over time. Additionally, fiberglass fabric exhibits remarkable resistance to chemical and environmental factors, such as moisture, UV radiation, and extreme temperatures. These qualities make it highly durable and suitable for a wide range of applications, including automotive, aerospace, marine, and construction industries. Furthermore, fiberglass fabric's durability is enhanced by its low maintenance requirements and long lifespan, making it a cost-effective and reliable choice for various projects.

- Q: What are the different widths available for fiberglass fabric rolls?

- Fiberglass fabric rolls typically come in various widths to accommodate different applications and preferences. The available widths can vary depending on the manufacturer, but some common options include 1 inch, 2 inches, 3 inches, 4 inches, 6 inches, 12 inches, and 24 inches. These widths are designed to provide flexibility and versatility for a range of projects, from small repairs and patching to larger-scale applications such as boat construction or automotive repairs. It is important to check with the specific supplier or manufacturer to determine the exact widths available for fiberglass fabric rolls, as they may offer additional or customized options to cater to specific needs.

Send your message to us

Fiberglass Roofing Fabric with Medium Silica Fiberglass Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords