Fiberglass Over Fabric Silica Glass Fiberglass Cloth with Vermiculite Coated

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

Vermiculite coated silica Fiberglass cloth is high-temperature resistant products, made by silica glass fiber cloth coat with vermiculite.

Application:

Widely use as heat resistant and ablation-resistant material for rocket, missile and space vehicle;

High-temperature resistant, thermal insulation, refractory material;

Dust collect for high temperature gas;

Liquid filtration & Sound absorbing and thermal insulation for vehicle, motor bicycle;

The thermal insulation protective materials for molten liquid filtration.

Product Capability:

Higher temperature resistant, higher thermal insulation, low thermal conductivity;

Thermal stability and chemical stability;

Good dielectric performance;

High strength and easy to manufacture;

Nontoxic and harmless to the environment.

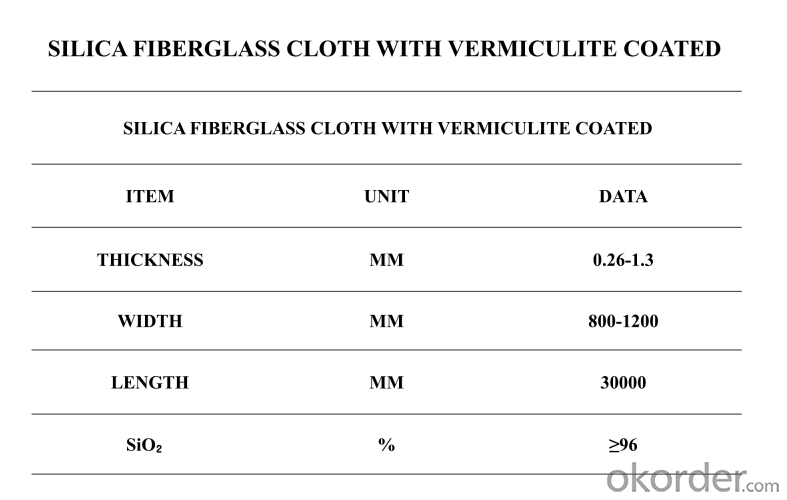

Data Sheet:

Silica fiber products: A kind of inorganic high temperature resistance fiber with the content of SiO₂ higher than 95%, its soften temperature can nearly reach to 1700℃.It can be used in high temperature environment below 900℃ for a long time.

- Q: Is fiberglass fabric resistant to chemicals used in oil and gas industry?

- Generally, fiberglass fabric is resistant to the chemicals typically used in the oil and gas industry. It is well-known for its exceptional chemical resistance, which makes it well-suited for a variety of industrial uses, including oil and gas applications. It can withstand exposure to a wide array of chemicals, such as acids, alkalis, solvents, and hydrocarbons commonly found in the oil and gas sector. The reason behind this resistance lies in the inert nature of the fiberglass material, as it does not react or deteriorate when exposed to these chemicals. Furthermore, the fabric's non-porous structure prevents the absorption of chemicals, thereby enhancing its resistance even further. In summary, fiberglass fabric is an excellent choice for applications that require chemical resistance in the oil and gas industry. Nonetheless, it is always advisable to consult with manufacturers or suppliers to ensure that the specific type of fiberglass fabric being used is suitable for the intended chemical environment.

- Q: Can fiberglass fabric be used for making aircraft parts?

- Yes, fiberglass fabric can be used for making aircraft parts. It is often used in the construction of lightweight and durable components such as fairings, radomes, and interior panels. Fiberglass fabric offers excellent strength-to-weight ratio and is resistant to corrosion, making it a suitable material for aviation applications.

- Q: What is the "three proof cloth"? How to correctly use the three proof cloth?

- Three cloth is coated on the surface of PVC, PTFE refractory fiber, flame retardant silicone and other refractory materials, make fire waterproof mildew proof function, refractory fiber with fire, PVC, PTFE, silica gel has a waterproof function.

- Q: Is fiberglass fabric easy to work with?

- Fiberglass fabric is generally acknowledged as being easy to handle. Its lightweight and flexible nature make it more manageable and malleable compared to other materials. It can be effortlessly cut into desired shapes and sizes using basic tools such as scissors or a utility knife. Moreover, fiberglass fabric is recognized for its exceptional strength and durability, making it suitable for a wide range of applications. It can be easily attached to various surfaces using adhesives or resin, and it can also be sewn or molded to create diverse forms. Nonetheless, like any material, working with fiberglass fabric may necessitate some practice and caution, especially when dealing with the microscopic glass fibers that can cause skin irritation or respiratory issues if not handled properly.

- Q: How is fiberglass fabric stored and transported?

- Fiberglass fabric is typically stored and transported in a way that ensures its protection and preservation. Firstly, it is important to keep the fabric in a dry and temperature-controlled environment to prevent moisture absorption and mold growth. The fabric rolls are usually stored vertically, on pallets or racks, to avoid any unnecessary pressure that may lead to deformation or damage. When it comes to transportation, fiberglass fabric is typically shipped in rolls. These rolls are often packaged in protective plastic wrap or bags to shield them from dust, dirt, and potential water damage during transit. Additionally, the rolls may be placed in sturdy cardboard boxes or placed on pallets to provide further support and prevent any shifting or movement during transportation. During transit, it is crucial to handle the fabric rolls with care to avoid any unnecessary stress or impact that may lead to tears or damages. This includes securing the rolls in the transportation vehicle using straps or other securing mechanisms to prevent movement and potential damage. Overall, proper storage and transportation of fiberglass fabric involve maintaining a suitable environment and taking precautions to protect the fabric from external elements and physical stress. By following these guidelines, the integrity and quality of the fiberglass fabric can be preserved, ensuring it arrives at its destination in optimal condition.

- Q: Can fiberglass fabric be used for reinforcement in underground storage tanks?

- Yes, fiberglass fabric can be used for reinforcement in underground storage tanks. Its high strength, corrosion resistance, and durability make it a suitable material for reinforcing the structure of underground storage tanks, ensuring their structural integrity and preventing leaks or failures.

- Q: Is fiberglass fabric resistant to salt spray in coastal areas?

- Indeed, in coastal areas, fiberglass fabric demonstrates resistance to salt spray. Renowned for its corrosion resistance and durability, fiberglass proves to be an exceptional option for marine-related purposes. Over time, salt spray, comprising corrosive salt particles, can inflict harm upon numerous materials. Nevertheless, fiberglass fabric is specifically engineered to endure the unforgiving conditions prevalent in coastal regions, including exposure to salt spray. It neither corrodes nor deteriorates when subjected to saltwater, rendering it an optimal selection for diverse marine applications like boat covers, sails, and awnings.

- Q: How does fiberglass fabric handle moisture and humidity?

- Fiberglass fabric is known for its excellent resistance to moisture and humidity. Unlike other materials, it does not absorb water or become weakened or damaged by exposure to moisture. This makes it highly durable and suitable for applications in high-humidity environments or areas prone to moisture.

- Q: How does fiberglass fabric perform in cryogenic temperatures?

- Due to its inherent properties, fiberglass fabric is able to perform exceptionally well in cryogenic temperatures. Cryogenic temperatures, which are defined as extremely low temperatures below -150°C (-238°F), are commonly encountered in applications such as aerospace, medical, and scientific research. One of the main reasons for the effectiveness of fiberglass fabric in cryogenic temperatures is its remarkable thermal insulation properties. This allows the fabric to effectively endure and safeguard against extreme fluctuations in temperature. Consequently, the structural integrity and performance of the fiberglass fabric remain intact even when subjected to cryogenic conditions. Moreover, fiberglass fabric exhibits a low level of thermal conductivity, meaning that it does not readily transfer heat. This characteristic is of utmost importance in cryogenic applications as it helps to minimize the transfer of heat between the extremely cold environment and the surrounding components. In addition to its exceptional thermal properties, fiberglass fabric also possesses high tensile strength, durability, and resistance to chemical corrosion. These qualities make it well-suited for use in cryogenic environments, where materials must endure extreme conditions and maintain their mechanical properties over an extended period of time. To summarize, fiberglass fabric offers dependable performance and protection in cryogenic temperatures, thus making it a favored choice in various industries that require materials capable of withstanding such harsh conditions.

- Q: Glass fiber cloth, heat conduction double sided adhesive tape and no material heat conduction double sided adhesive tape difference? Which is better?

- Fiberglass cloth thermal double-sided tape (www.glpoly ): it is made of glass fiber cloth, PET, PVC film, non-woven material, double-sided evenly coated elastomer pressure-sensitive adhesive or resin adhesive, acrylic pressure-sensitive adhesive, adhesive made in the substrate roll or sheet belt, is composed of a substrate, adhesive, isolation of paper (film) parts.

Send your message to us

Fiberglass Over Fabric Silica Glass Fiberglass Cloth with Vermiculite Coated

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords