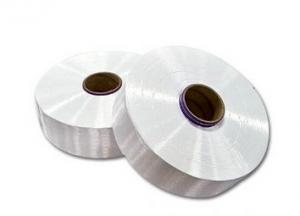

FDY polyester filament yarn raw white semi-dull

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of FDY Yarn

Material | 100% polyester |

Type | FDY (Fully Drawn Yarn), semidull |

Structure | Multifilament Yarn, Continuous Filament |

Color | White and Black |

Feature | Eco-Friendly, High Strength, |

Application | Knitting, Weaving, Sewing, Embroidery |

Specification | 11-167dtex, 12-144F |

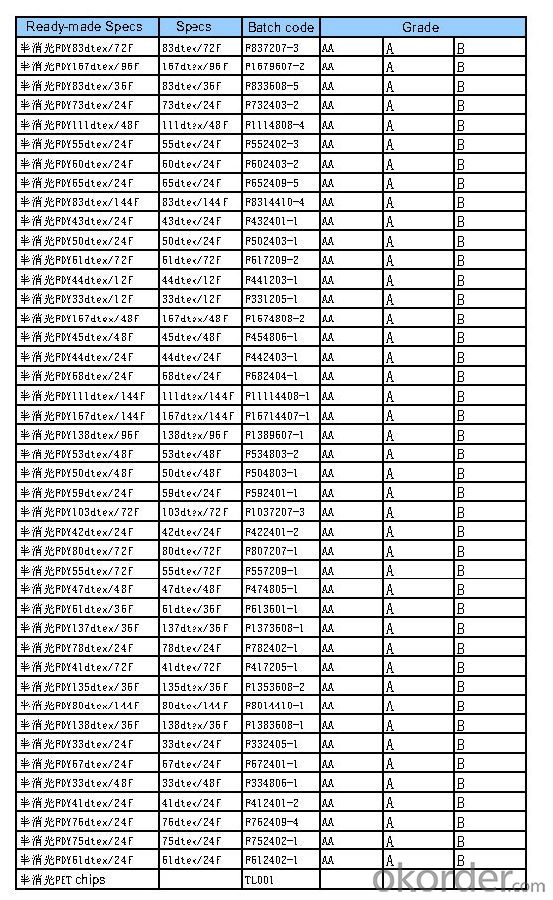

Regular Specifications

Structure:

1). sheath-core structure: low melting polyester+polyester, Low melting polyester content:30%~40%

2). 100 pure low melting polyester

Feature:

Low melting polyester will be melted at 110/180 degree Celsius and be endowed with adhesive property.

Use low melting polyester is harmless, and enhances the strength of the fabric.

The fabric made with low melting polyester yarn is with high strength, washable, stiff and smooth, easy care.

Low melting polyester yarn owns good adhesiveness and stability, adhesive quickly.

The processing is simple, low energy consumption, nonhazardous, no pollution, Eco-friendly.

Application and suggestion:

1. The adhesive of two layers of sports shoe Upper material —FDY 50D/75D

2. Soft curtain, Zebra curtain, Roman curtain—FDY 75D/150D

3. Vertical blinds—FDY 250D

4. Filter net for air condition—FDY 30D/50D/75D/150D

5. Electromagnetic wire: PET-Glass fiber blended fiber—FDY 50D/75D

6. Garment lining cloth for suit, tie, hat, etc. —FDY 150D/50D/420D

7. Warp knitting fabric such as: Stiff mesh fabric, medical/food filter net, inner car decoration.

8. Top-grade eco-friendly filter material

9. Other applications: protective gloves, dust gauze, top-grade window screen, invisible screen, etc.

- Q: Why in general the yarn in the woven fabric strength coefficient of use greater than 1

- (2) combed yarn: cotton yarn is combed by the spinning system spinning yarn. Combing yarn selection of high-quality raw materials, yarn in the fiber straight parallel, knot less, good gloss, dry, high strength, this type of cotton yarn used for weaving high-grade fabric

- Q: How does textile twist yarn identify?

- Therefore, in the detection of the composition of the textile, we can extract several from the fabric edge of the warp and weft, untwisted to form a loose as a sample, on the fire burning

- Q: What is the textile bobbin?

- The textile bobbin is a tubular body whose inner hole is matched with the spinning machine spindle, characterized in that the bobbin tube wall has a plurality of holes.

- Q: In the textile fabric, mesh cloth and the difference between the Bali yarn is what

- In the textile fabric, the mesh cloth and the difference between the Bali yarn if the mesh-shaped small holes in the fabric can be used cotton or chemical fiber blended yarn (line) weaving, but also useful yarn and thread intertwined. There are white weave or yarn-dyed, but also a large jacquard, can be woven out of different patterns. Good ventilation, the dyeing and dyeing processing, cloth body very cool, in addition to summer clothing, especially suitable for curtains, mosquito nets and other supplies.

- Q: Textile spinning yarn should be done first what to do

- Merchandiser refers to the company in the course of operation, customer orders as the basis, tracking products, tracking the flow of services to the full-time staff. (Not part-time, alternative) all around the order to work, the delivery of the person responsible for the delivery, are Merchandiser.

- Q: What is the reason why the textile yarns are yarn

- Fine is the most widely used wool varieties, whether it is infants, children, women or men's clothing can be used for such rough wool weaving, weaving pattern fine and elegant.

- Q: How to choose the twist of the roving?

- Roving twist factor is too small, easy to produce accidental drawing, increase the broken, so that the product is not uniform.Therefore, the roving twist coefficient is the same as the drafting factor, roller pressure, roller gauge, etc. The roving twist factor is mainly based on The length of the fiber, the spinning varieties, the thickness of the roving, the post-spinning process and the temperature and humidity factors to choose to control:

- Q: What is the yarn inside the textile industry is what kind of yarn?

- Direct dye can be stained, is the natural fiber. And then go to the performance of the fiber, the dissolution test, to come to a certain type.

- Q: What is the diameter of a yarn of 40 yarns?

- Where 0.040 is the common diameter coefficient of the medium cotton yarn; if the high diameter cotton yarn (fine cotton yarn) is the common diameter coefficient is 0.037; this coefficient can be based on the yarn volume specific gravity (g / C㎡) formula.

- Q: What is the yarn in the textile

- Usually in two or more loom to work together, the distance and the yarn used is not the same when there may be gripping yarn appears, and high-twist combed yarn generally do not produce gripping yarn.

Send your message to us

FDY polyester filament yarn raw white semi-dull

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches